Phase difference transmission system of engine fuel injection pump

A transmission system, fuel injection pump technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as inability to inhale or be extruded, slow opening time of the oil outlet valve, incomplete combustion of diesel oil, etc., to achieve Reduce emissions and pollution, improve fuel injection efficiency, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

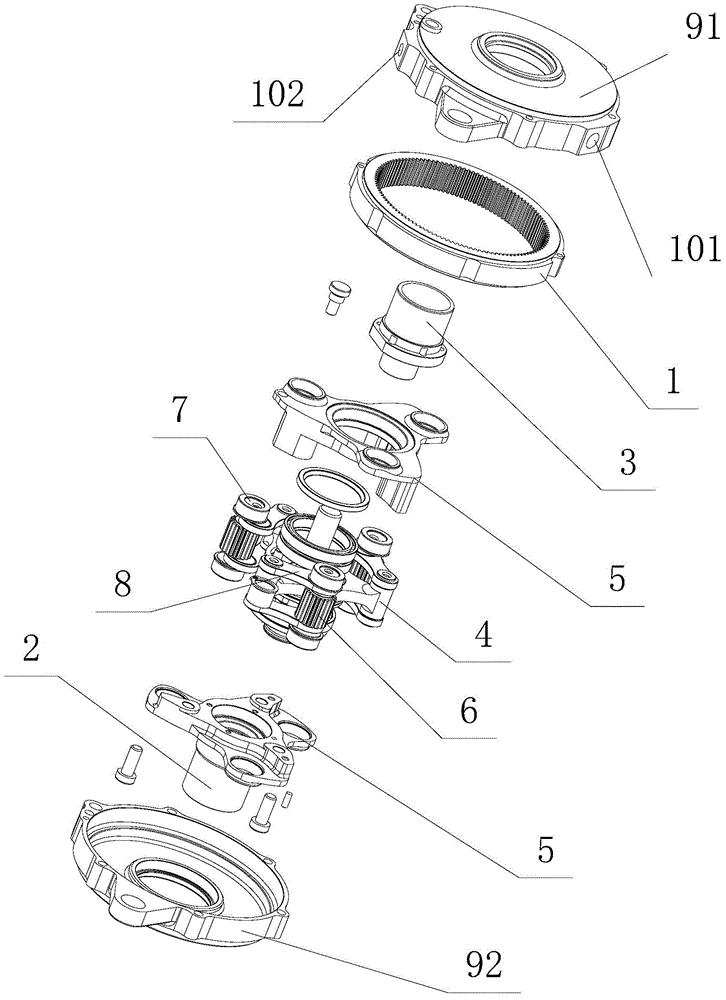

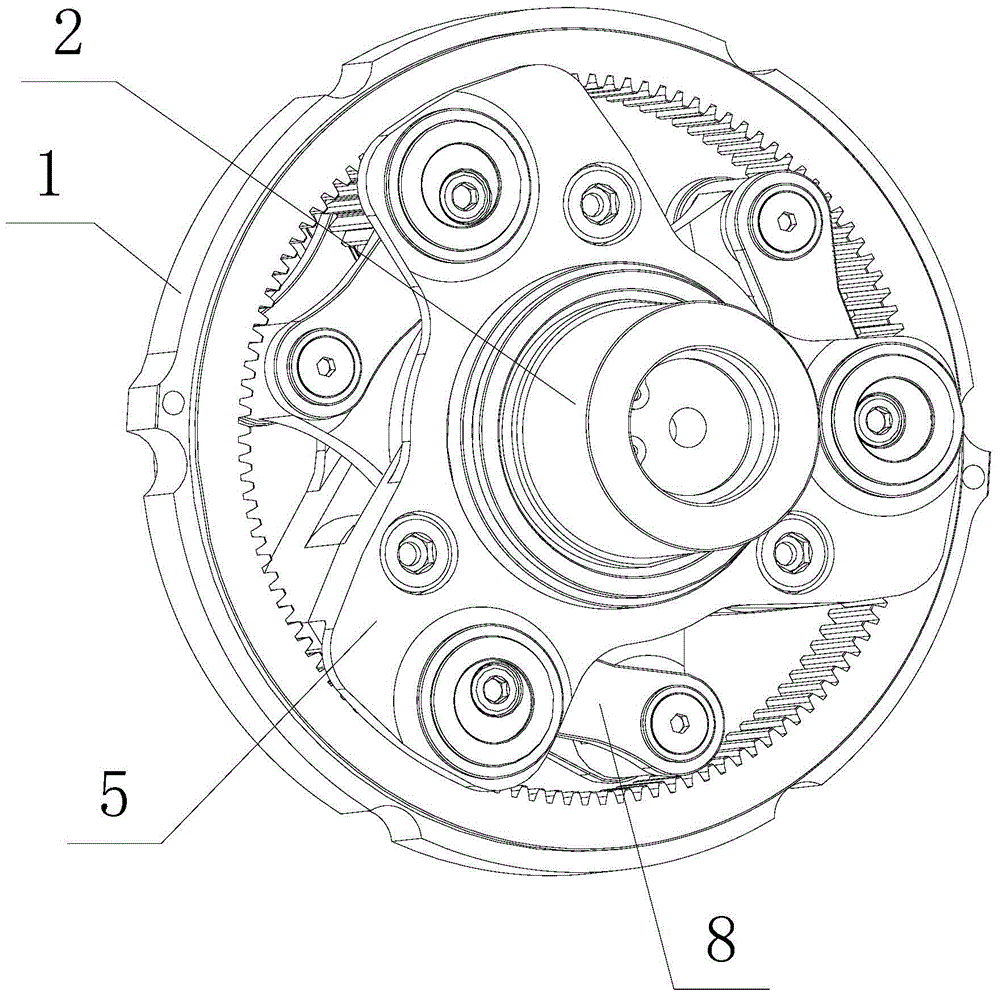

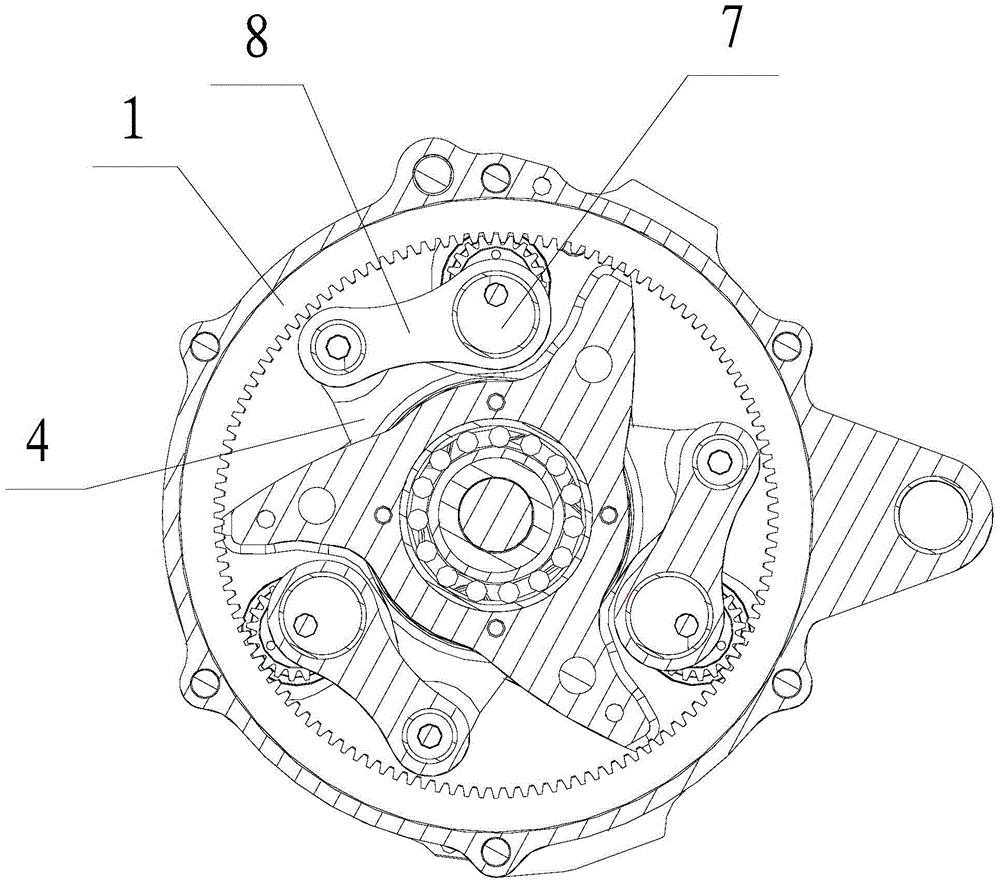

[0026] refer to Figure 1 to Figure 9 , the present invention provides a phase difference transmission system of an engine fuel injection pump, which is used to control the fuel injection time of the fuel injection pump, which includes: a housing, a clutch flange 2, a main shaft adapter 3, a main shaft flange 4, a planetary gear carrier 5, The eccentric wheel 7 and the connecting rod 8; the housing includes a left end cover 91 and a right end cover 92 connected by bolts, and the sealing connection is realized by a sealing ring between the left end cover 91 and the right end cover 92, and there is a cooling valve on the side wall of the housing. The oil inlet 101 and the oil outlet 102 of the housing are fixedly installed with the ring gear 1; the clutch flange 2 for power input is rotatably installed at one end of the housing through a bearing; the main shaft for power output The adapter 3 is rotatably installed on the other end of the housing through a bearing, and is coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com