Orthotropic steel bridge deck structure with HRP cover plate

A steel bridge deck, orthotropic technology, used in bridges, bridge construction, bridge parts, etc., can solve problems such as high welding process requirements, poor fatigue resistance, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

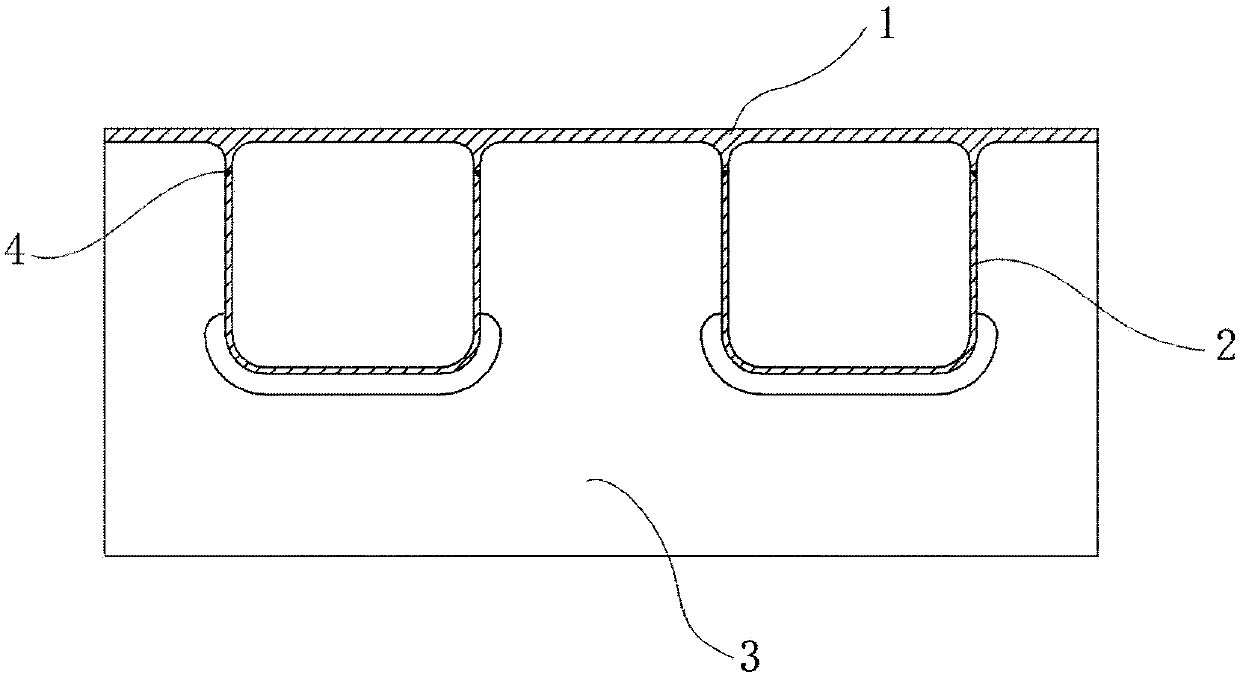

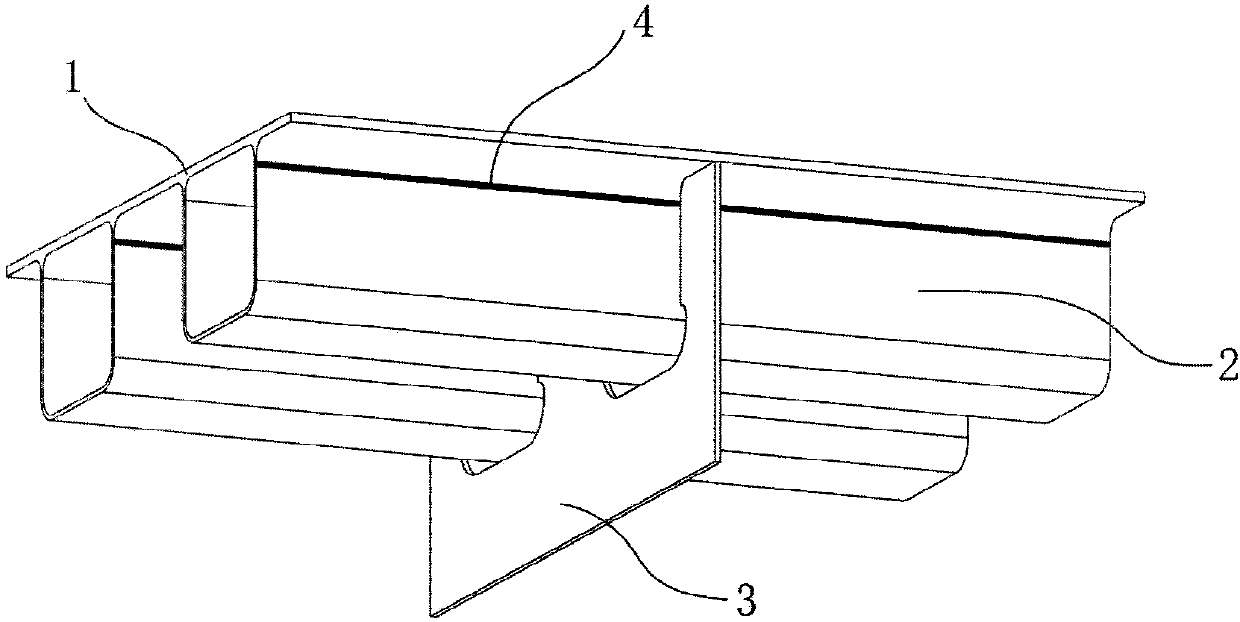

[0039] This embodiment discloses an HRP orthotropic steel bridge deck structure, which includes an HRP cover plate 1 , longitudinal ribs 2 and transverse ribs 3 .

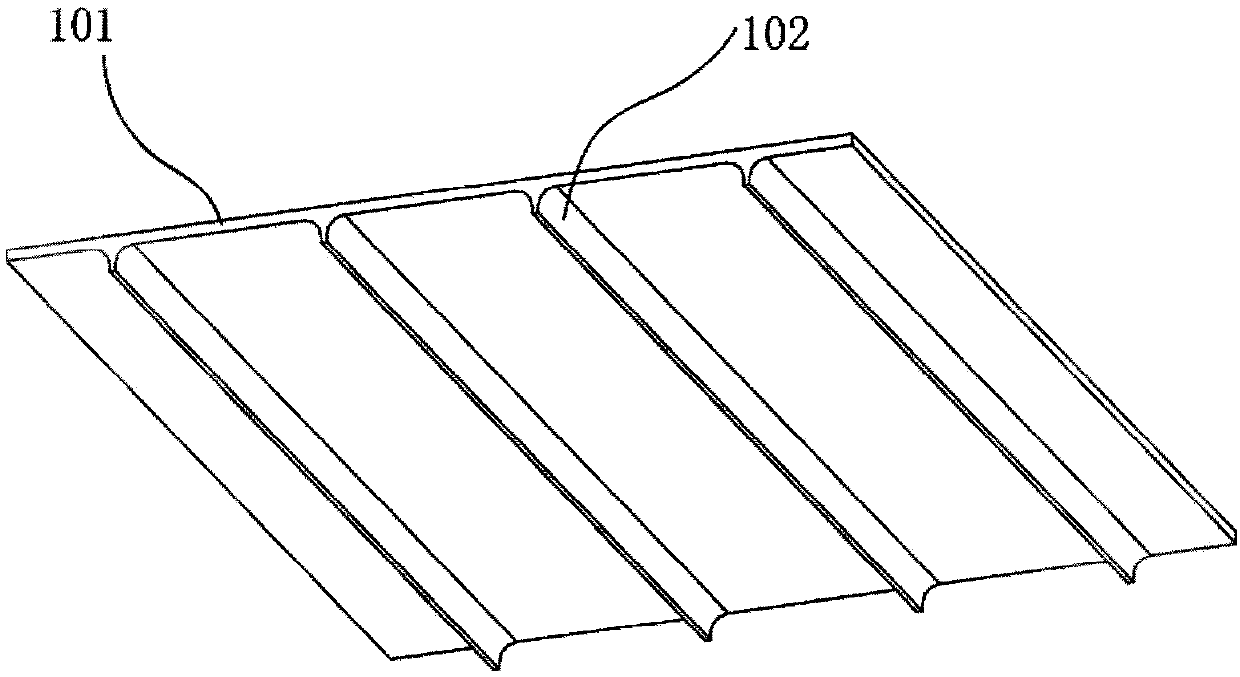

[0040] see figure 1 , the HRP cover plate 1 is a hot-rolled ribbed steel plate with four ribs 102 rolled on a flat plate 101 . The HRP cover plate 1 is continuously rolled and integrally formed. The ribs 102 appear on the lower surface of the plate 101 at intervals along the direction of the transverse bridge. The connecting portion between the flat plate 101 and the rib 102 adopts a circular arc-shaped gradual transition, which effectively reduces the stress concentration of the component at this position and improves fatigue resistance.

[0041] see Figure 4 , the longitudinal rib 2 is a closed rib with a U-shaped cross section. The plate thicknesses of the plate 101 and the rib 102 are different. The two ends 201 of the longitudinal rib 2 are respectively welded to two adjacent ribs 102 . The longitudinal...

Embodiment 2

[0045] This embodiment discloses an HRP orthotropic steel bridge deck structure, which includes an HRP cover plate 1 , longitudinal ribs 2 and transverse ribs 3 .

[0046] see Figure 5 and Figure 6 , the HRP cover plate 1 is a hot-rolled ribbed steel plate with eight ribs 102 rolled on a flat plate 101 . The HRP cover plate 1 is rolled by special rolls 5 . The ribs 102 appear on the lower surface of the plate 101 at intervals along the direction of the transverse bridge. The smooth transition between the flat plate 101 and the rib 102 can effectively reduce the stress concentration of the component at this position and improve fatigue resistance.

[0047] The longitudinal rib 2 is a closed rib with a trapezoidal cross section. The plate thicknesses of the plate 101 and the rib 102 are different. The two ends 201 of the longitudinal rib 2 are respectively welded to two adjacent ribs 102 . The longitudinal rib 2 is welded to the rib 102 through a butt full penetration we...

Embodiment 3

[0051] This embodiment discloses an HRP orthotropic steel bridge deck structure, which includes an HRP cover plate 1 , longitudinal ribs 2 and transverse ribs 3 .

[0052] see Figure 7, the HRP cover plate 1 is a hot-rolled ribbed steel plate with five ribs 102 rolled on a flat plate 101 . The HRP cover plate 1 is rolled by special rolls 5 . The ribs 102 appear on the lower surface of the plate 101 at intervals along the direction of the transverse bridge. The smooth transition between the flat plate 101 and the rib 102 can effectively reduce the stress concentration of the component at this position and improve fatigue resistance.

[0053] The longitudinal rib 2 is an open rib, which adopts the cross section form of unequal angle steel. The plates 101 and ribs 102 have the same plate thickness. The longitudinal rib 2 is welded to the rib 102 through a butt full penetration weld 4 . In this embodiment, the longitudinal rib 2 is integrally formed by hot-rolled section ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com