Corrugated steel web temporary fixation structure independent of template

A corrugated steel web and temporary fixing technology, which is applied in construction, bridge construction, bridges, etc., can solve problems such as difficult adjustments and changes, and achieve the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

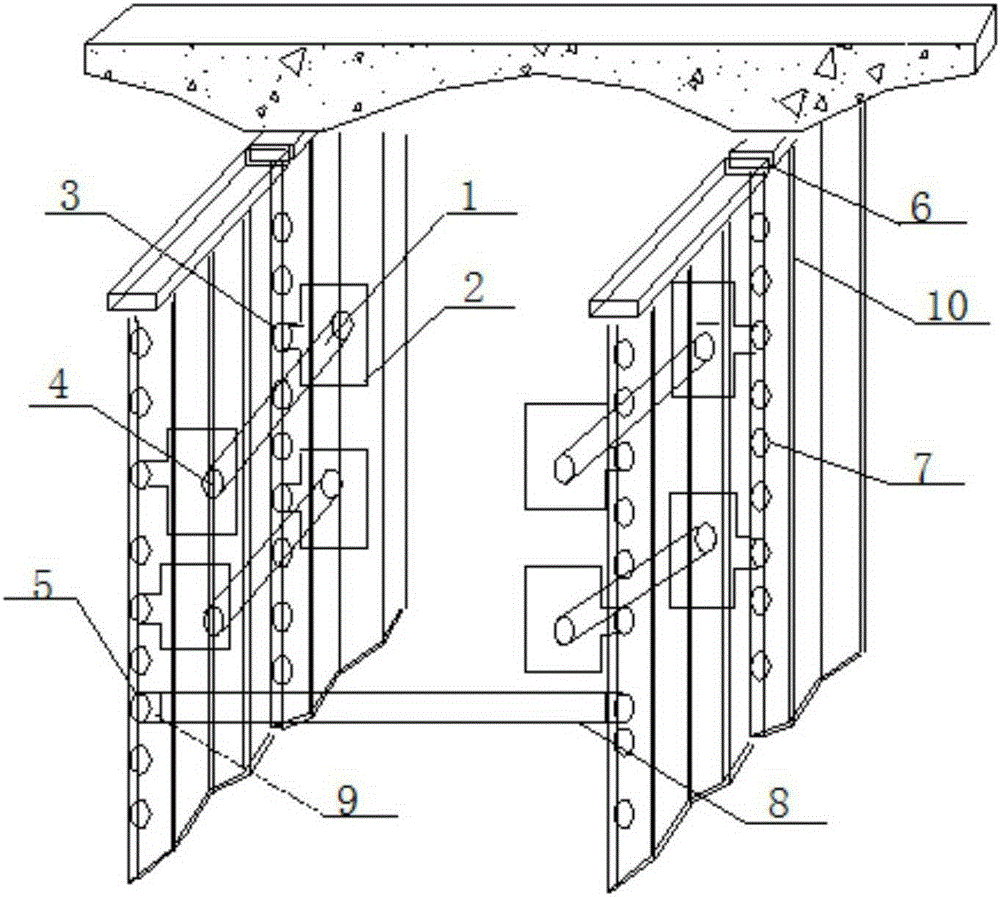

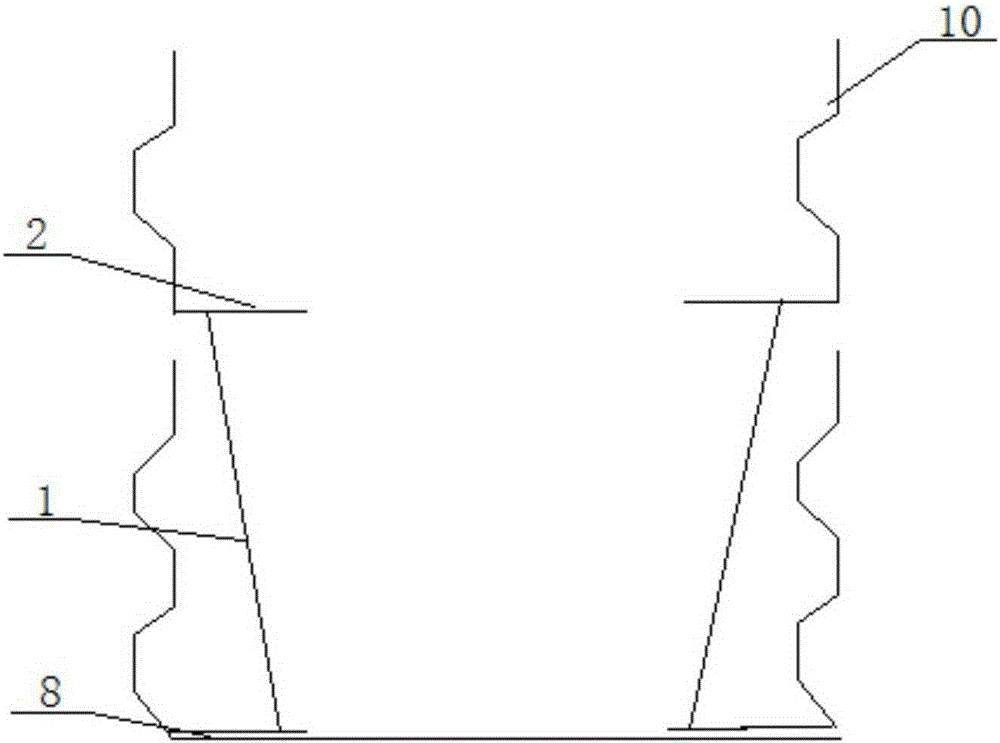

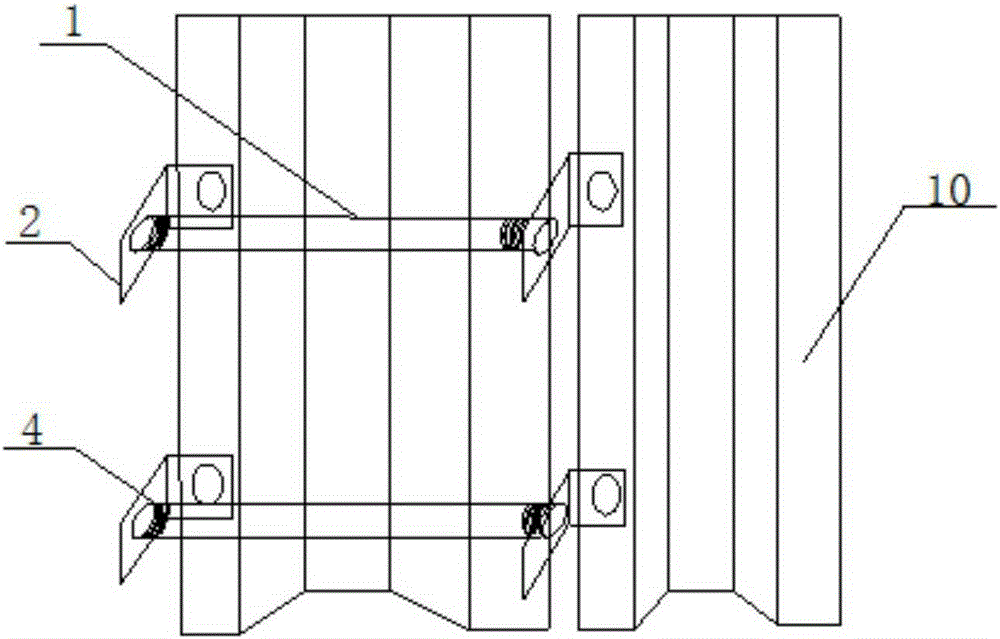

[0026] Such as Figure 1~4 The schematic diagram of the temporary fixing structure of the corrugated steel web independent of the formwork shown in the present invention respectively includes a longitudinal steel brace 1, a first bent steel plate 2, a first reserved hole 3, a second reserved hole 4, a third reserved Retained holes 5, welded steel bars 6, fourth reserved holes 7, transverse steel braces 8, second bent steel plates 9 and corrugated steel web segments 10.

[0027] Taking a group of adjacent corrugated steel web segments 10 as an example, the specific structure of the present invention is described as follows:

[0028] Two corrugated steel web segments 10 are arranged adjacently, and two adjacent corrugated steel web segments 10 are arranged opposite to the two adjacent corrugated steel web segments 10 . Two adjacent corrugated steel web segments 10 are fixedly connected by longitudinal steel braces 1, and two opposite corrugated steel web segments 10 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com