Tile-type combined roller cover

A combination of roller and tile technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of long hot charging process, scrapped roller skin, high requirements for site and tools, reduce the risk of cracking, and be easy to process and manufacture , Easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

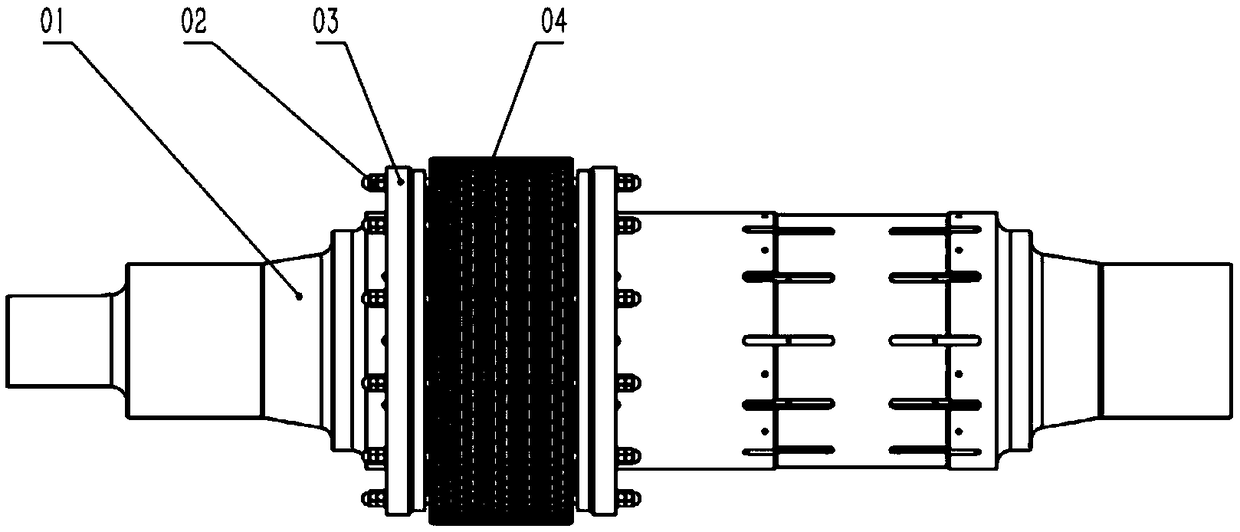

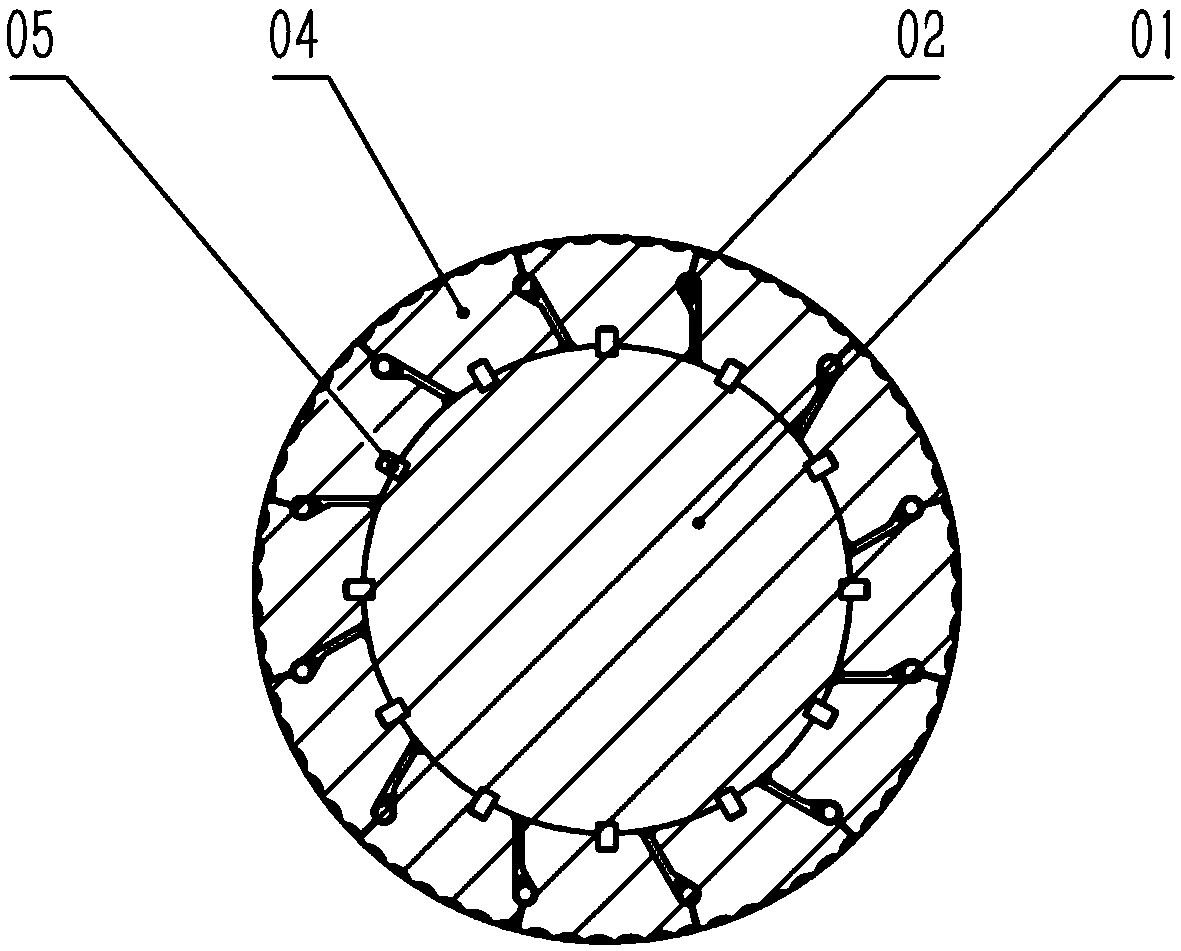

[0018] As an embodiment of the tile-type combined roll skin of the present invention, such as figure 1 and figure 2 As shown, it includes a roller leather block 04, a roller leather hoop 03, a screw fastener 02, a roller leather key 05, and a roller shaft 01. The roller leather block 04 has pillow-shaped concave pockets in a honeycomb arrangement, with tapered bosses on both sides, a concave-convex mortise and tenon structure on the inner arc surface, and key grooves on the inner arc surface; the roller leather hoop 03 has a tapered boss, and the inner arc surface is slotted corresponding to the position of the roller skin key 05; the screw fastener 02 is composed of a full-length screw that runs through the roller skin and the roller hoops at both ends, and hexagonal nuts at both ends and Composed of cap nuts; the roller skin key 05 has a stepped hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com