Electric gate valve

A plug-in valve, electric technology, applied in sliding valves, valve details, valve devices and other directions, can solve the problems of polluted materials, large friction resistance, heavy weight, etc., to achieve low energy consumption, low friction resistance, high load-bearing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

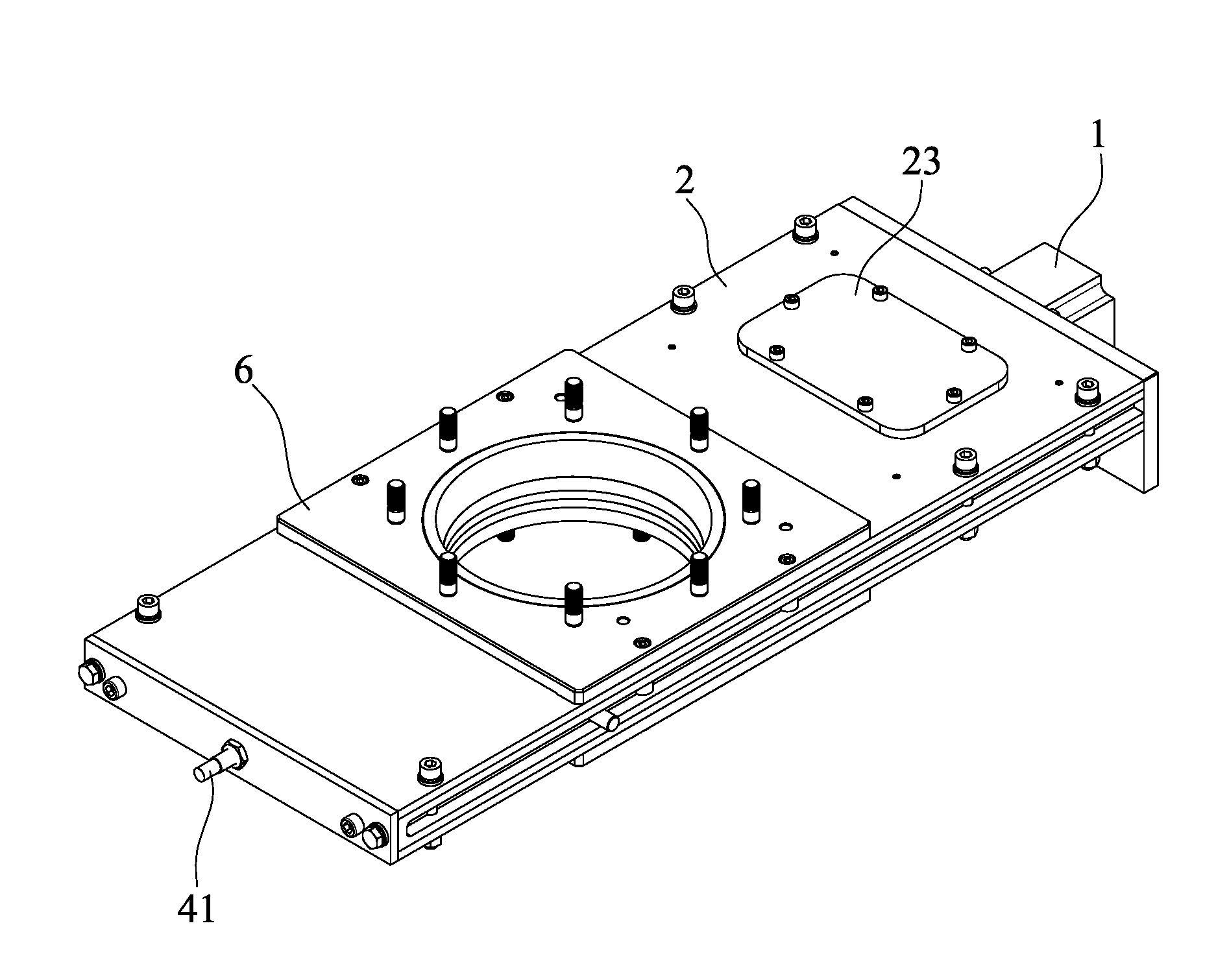

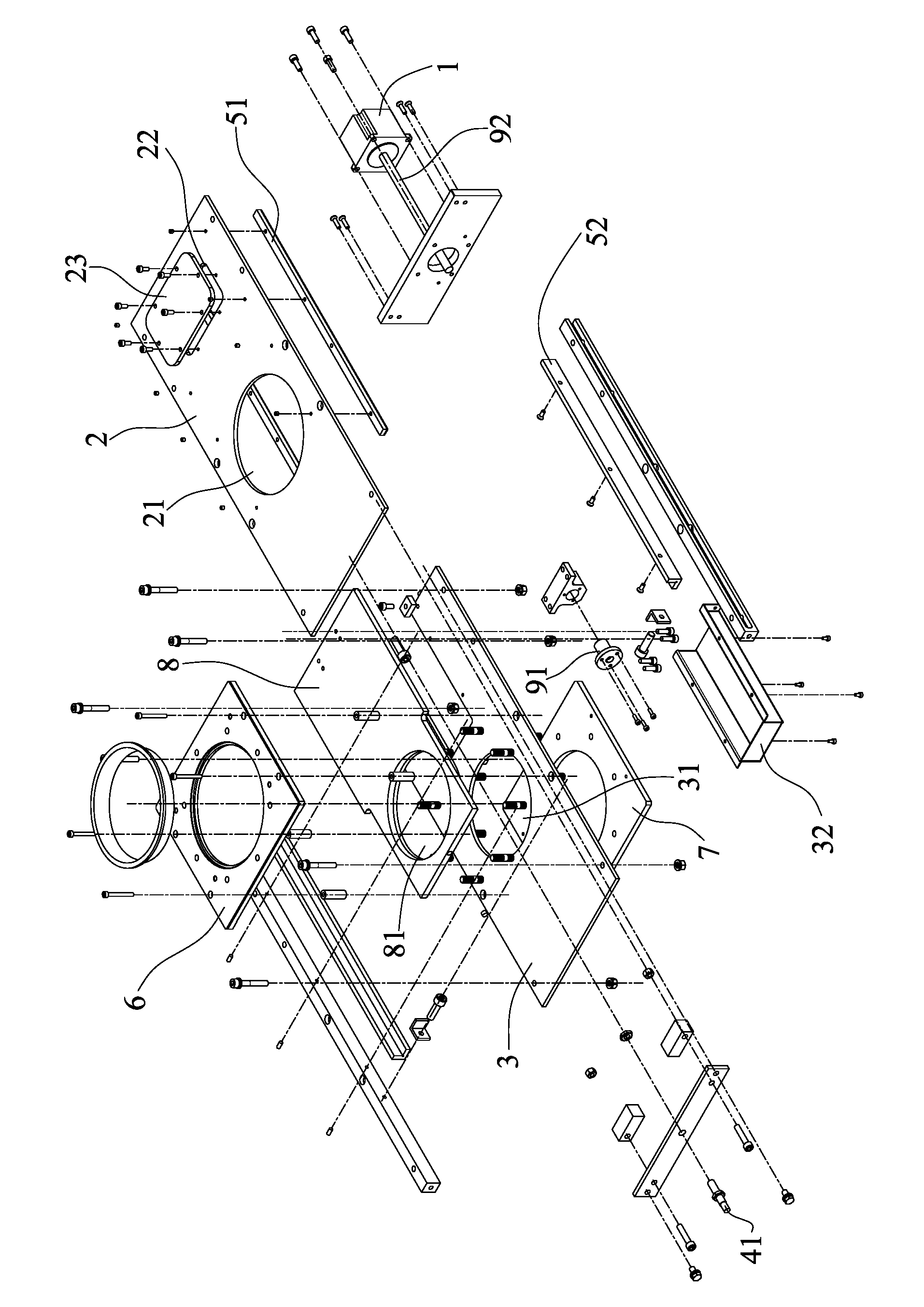

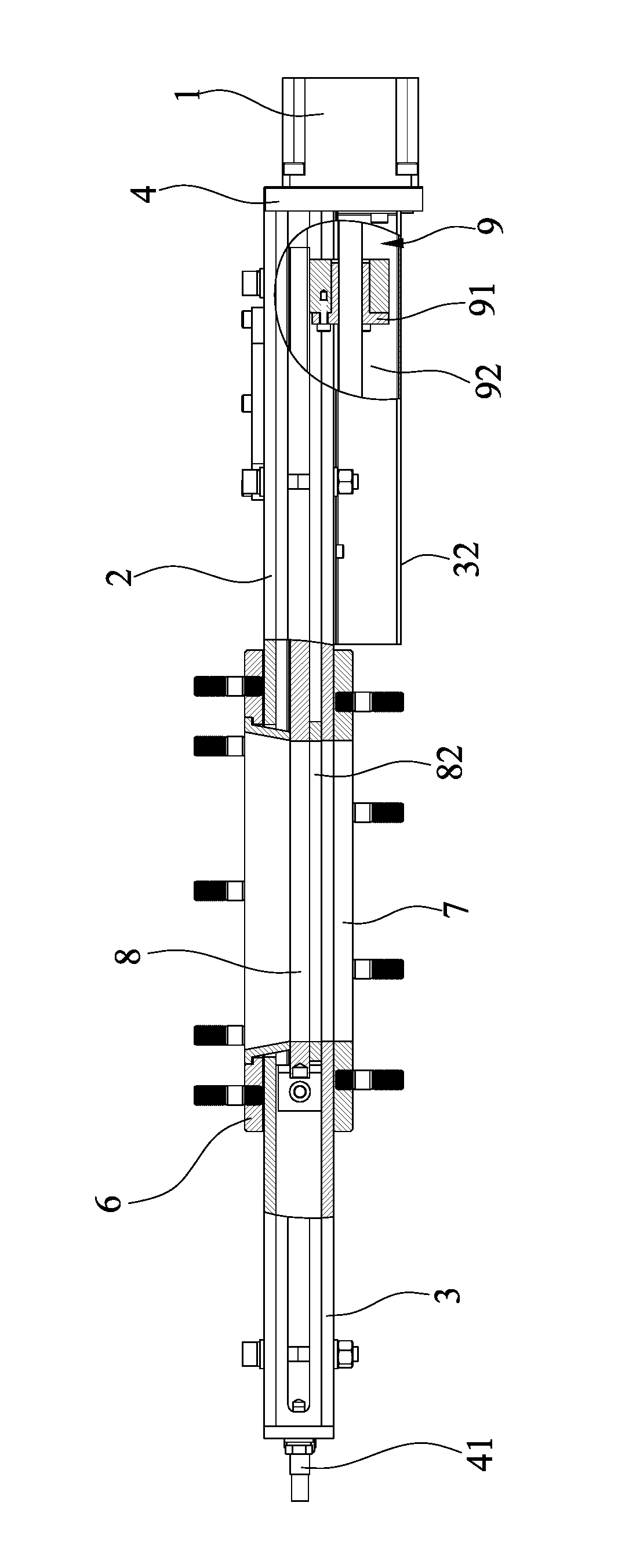

[0049] refer to Figure 1 to Figure 4 As shown, an electric gate valve disclosed by the present invention includes a motor 1 , an upper end cover 2 , a lower end cover 3 , a valve body frame 4 , a slide rail 5 , an inlet flange 6 , an outlet flange 7 and a valve plate 8 .

[0050] The upper end cover 2 is installed on the valve body frame 4, and the upper end cover 2 has a material inlet 21, and the inlet flange 6 is installed on the upper end cover 2 material inlet 21; the valve body frame 4 can be composed of the front valve body frame, the rear The valve body frame, the left valve body frame and the right valve body frame are assembled, and this structure can better ensure the airtightness of the present invention; it can also be integrally formed.

[0051] The lower end cover 3 is installed on the valve body frame 4 , the lower end cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com