Traction-type tool derrick rig for replacing derricks of steel tube truss-concrete arch bridge

A steel tube truss and concrete technology, applied in arch bridges, bridge forms, erection/assembly of bridges, etc., can solve the problems of high engineering work intensity, high construction cost, complicated construction procedures, etc., and achieve fast construction installation and dismantling. The effect of low strength and convenient standardized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

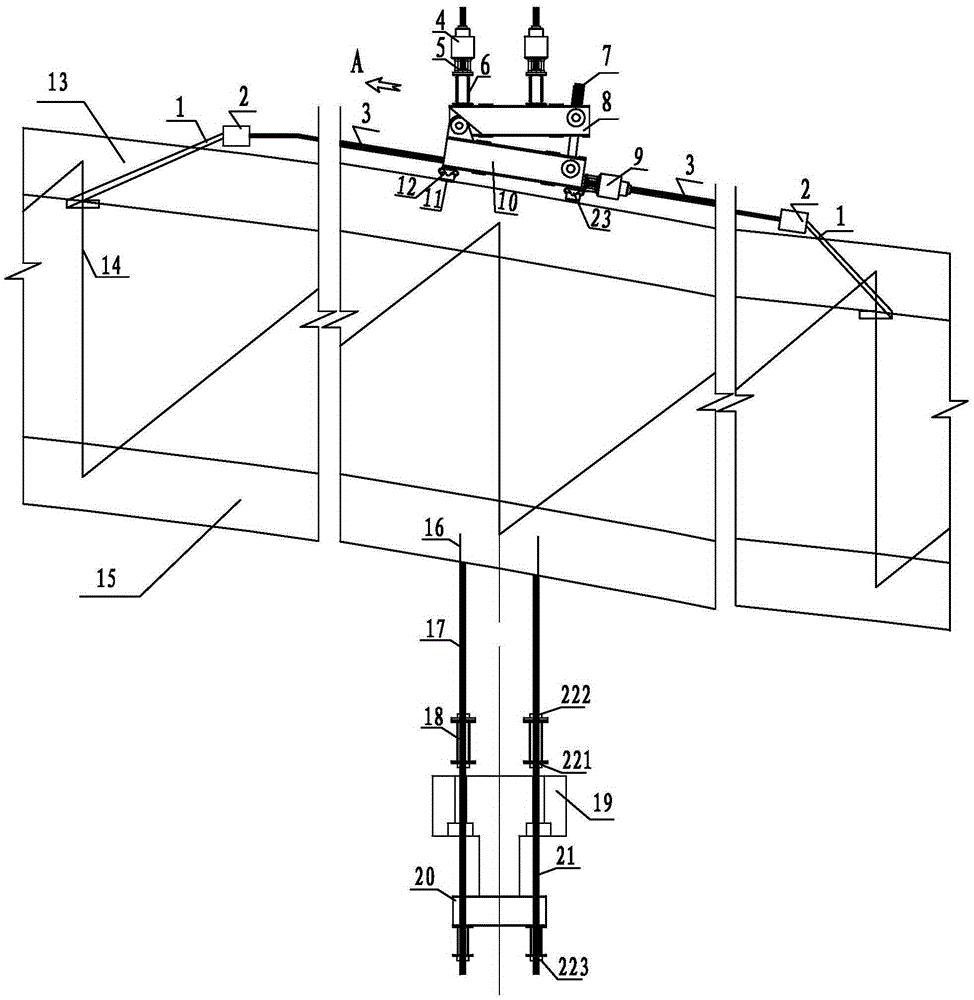

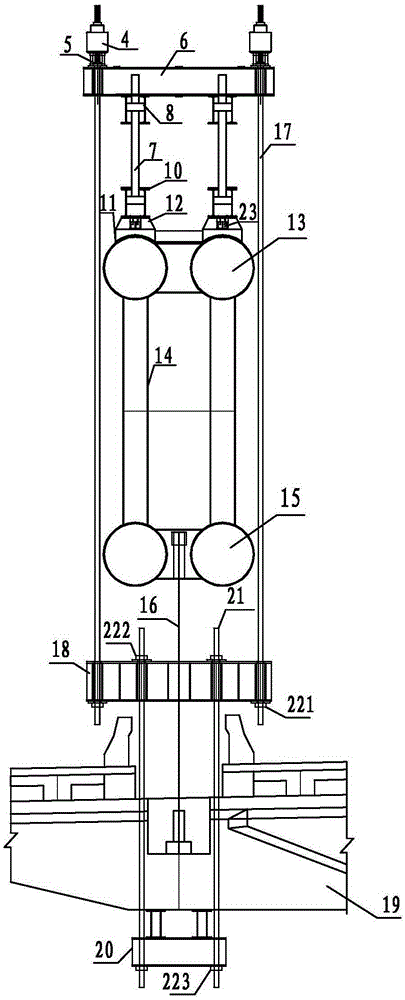

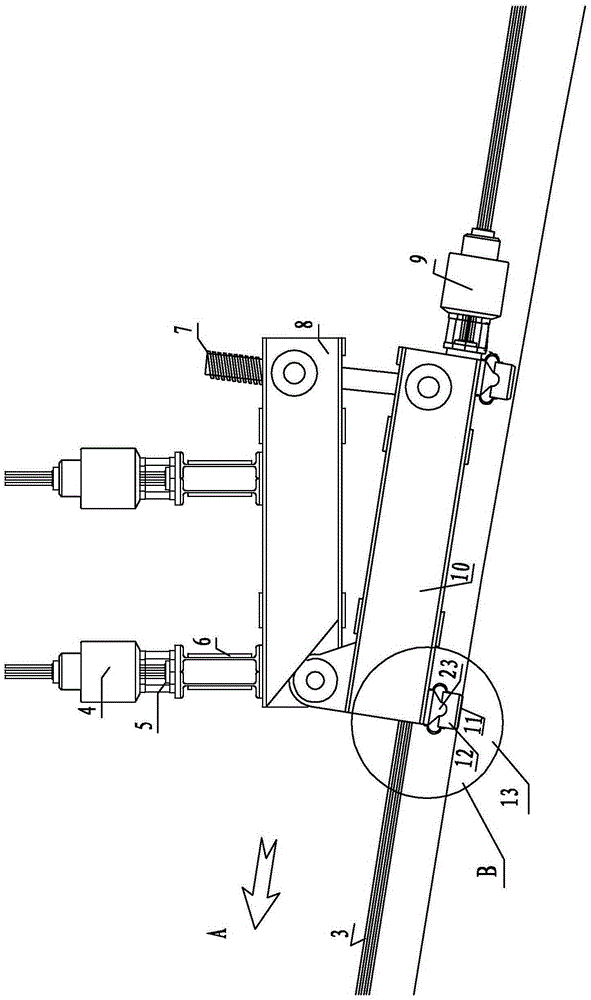

[0023] The utility model relates to a traction tool hanger device for replacing the hanger of a steel pipe truss concrete arch bridge.

[0024] Such as figure 1 , figure 2 As shown, the traction tool boom device for replacing the boom of the steel pipe truss concrete arch bridge includes a fixed end anchor, a tension end anchor 5, an upper conversion beam 18, a temporary boom 16 and a hanging device, namely: the lower Joist 20;

[0025] The difference from the existing tool hanger device is that the traction tool hanger device for replacing the hanger rod of the steel pipe truss concrete arch bridge of the present invention also includes a traction type vault anchorage anti-skid system installed on the arch of the steel pipe truss concrete arch bridge , the traction vault anchorage anti-skid system is composed of a sling 1, an anchor beam 2, a traction cable 3, a traction jack 9, a sliding shoe 12, a skateboard 11, a walking mechanism 10, a leveling mechanism 8, a beam 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com