Prevention device and method for seal integrality failure of casing annulus of gas well

A casing annulus and integrity technology, applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the lack of solutions and control means, casing annulus sealing failure, cement sheath damage, etc. problems, to achieve the effect of preventing casing annulus seal integrity failure, avoiding failure damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

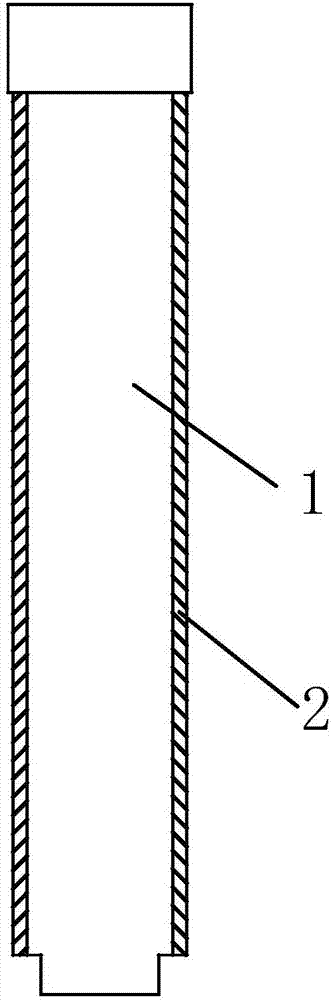

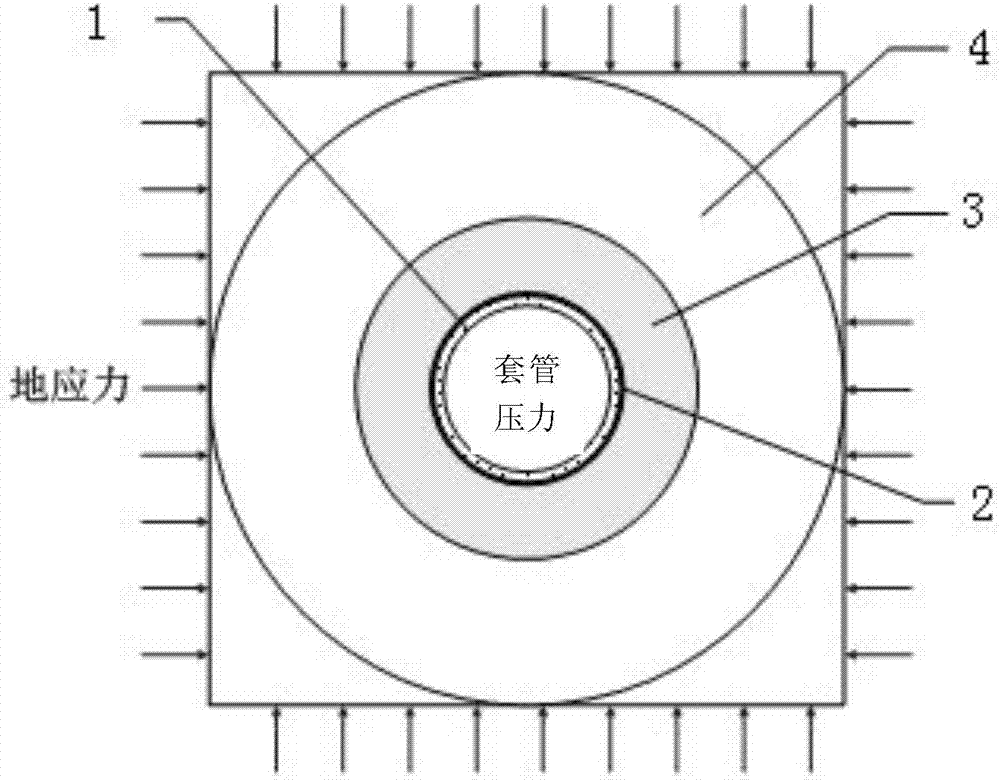

[0044] A gas well casing annulus sealing integrity failure prevention device includes a sleeve 2 adhered to the outer periphery of the casing 1 and used to protect the cement sheath 3 under force. Wherein, the elastic modulus of the sleeve is 5MPa, the Poisson's ratio is 0.25, and the thickness is 4mm.

[0045] The material used to prepare the sleeve includes the following components in parts by weight: 100 parts of nitrile rubber; 5 parts of vulcanizing agent DCP; 0.45 parts of vulcanizing agent sulfur; 25 parts of high wear-resistant carbon black; 5 parts of semi-reinforcing carbon black ; 2 parts of anti-aging agent 445; 0.5 part of accelerator zinc oxide; 0.4 part of accelerator active magnesium oxide.

[0046] The present invention also provides a method for preventing the failure of gas well casing annulus sealing integrity, comprising the following steps:

[0047] S1: Perform dust removal, cleaning, sandblasting, and degreasing treatment on the outer periphery of the c...

Embodiment 2

[0052] A gas well casing annulus sealing integrity failure prevention device includes a sleeve 2 adhered to the outer periphery of the casing 1 and used to protect the cement sheath 3 under force. Wherein, the elastic modulus of the sleeve is 10MPa, the Poisson's ratio is 0.5, and the thickness is 8mm.

[0053] The material used to prepare the sleeve includes the following components in parts by weight: 100 parts of nitrile rubber; 7 parts of vulcanizing agent DCP; 0.9 parts of vulcanizing agent sulfur; 60 parts of high wear-resistant carbon black; 15 parts of semi-reinforcing carbon black ; 3 parts of anti-aging agent 445; 1 part of accelerator zinc oxide; 0.8 part of accelerator active magnesium oxide.

[0054] The method for preventing the failure of the gas well casing annulus sealing integrity is the same as that in Embodiment 1.

Embodiment 3

[0056] A gas well casing annulus sealing integrity failure prevention device includes a sleeve 2 adhered to the outer periphery of the casing 1 and used to protect the cement sheath 3 under force. Wherein, the elastic modulus of the sleeve is 7MPa, the Poisson's ratio is 0.35, and the thickness is 6mm.

[0057] The material used to prepare the sleeve includes the following components in parts by weight: 100 parts of nitrile rubber; 6 parts of vulcanizing agent DCP; 0.65 parts of vulcanizing agent sulfur; 45 parts of high wear-resistant carbon black; 10 parts of semi-reinforcing carbon black ; 3 parts of anti-aging agent 445; 0.7 part of accelerator zinc oxide; 0.6 part of accelerator active magnesium oxide.

[0058] The method for preventing the failure of the gas well casing annulus sealing integrity is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com