A kind of water-soluble antibacterial monocarboxyl chitosan and its preparation method and application

A single carboxyl group, chitosan technology, applied in textile and papermaking, fiber processing, animal fiber and other directions, to achieve the effect of simple process, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

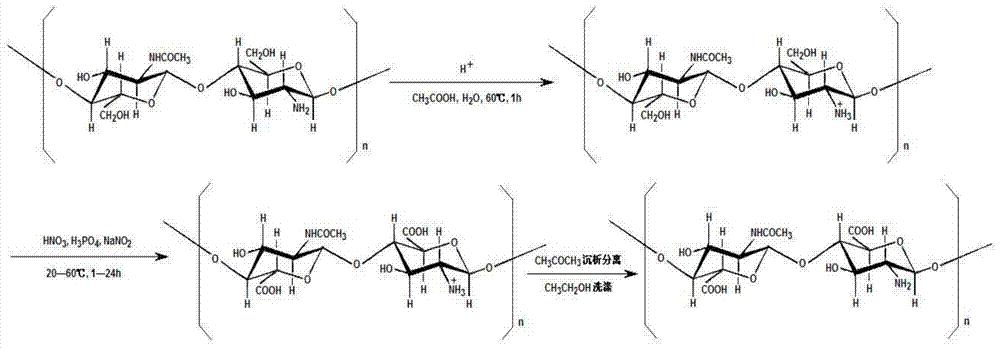

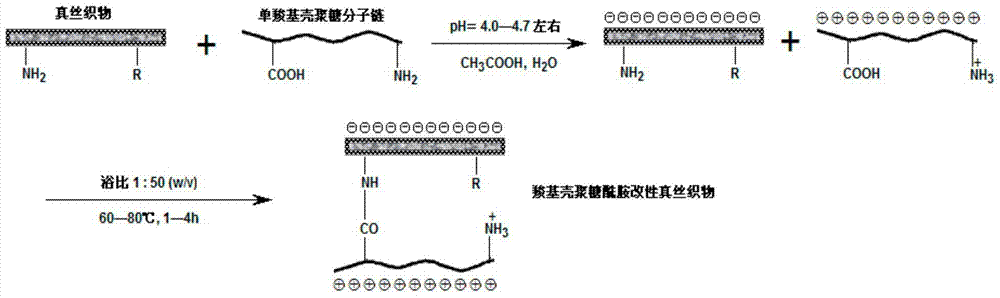

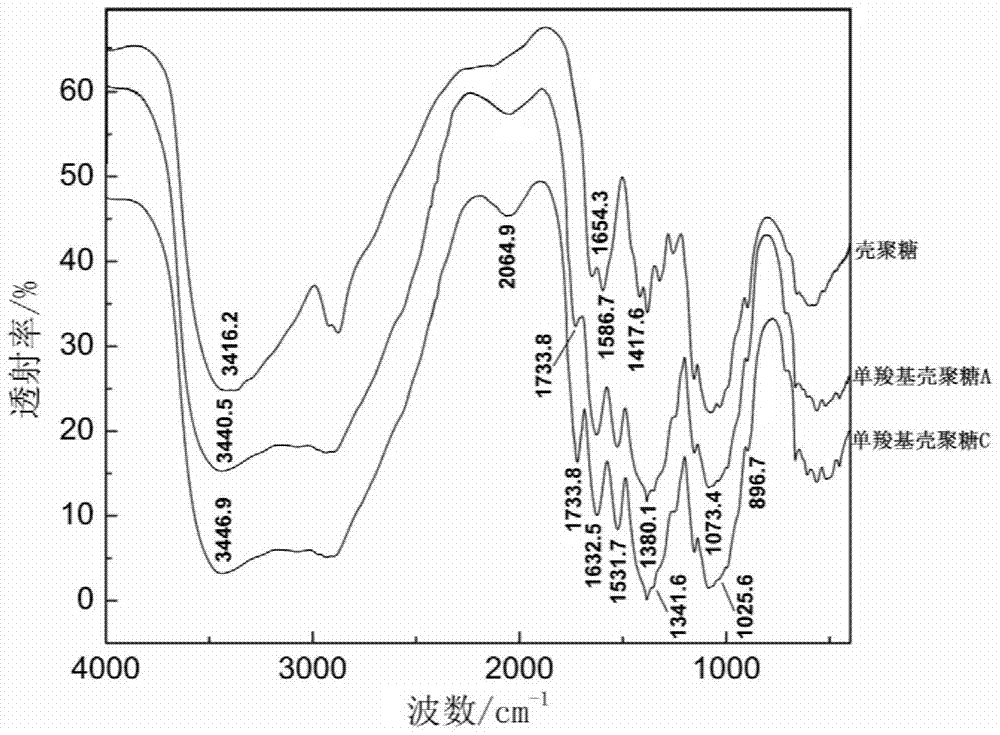

[0037] Embodiment 1: monocarboxy chitosan preparation

[0038] Weigh 4.0g of chitosan with a viscosity-average molecular weight of 800,000 and a deacetylation degree of 85% and place it in a 2% (v / v) dilute acetic acid solution at a bath ratio of 1:25 (w / v), stir at 60°C Dissolve in 1 hour, cool to 40°C and add 15mL of mixed acid (V 浓硝酸 :V 浓磷酸 =1:1), then add sodium nitrite with a mass volume ratio of 0.007g / mL to the mixed acid in a light-proof airtight container, and slightly shake it at 40°C for 2 hours, and immediately add 230mL of absolute ethanol after the reaction Terminate the oxidation reaction, the oxidation product is precipitated with acetone, vacuum filtered until the pH of the filtrate is about 6, washed with absolute ethanol, vacuum dried and refined to obtain a light yellow monocarboxyl group with a molecular weight of 180,000 and a carboxyl degree of 29.72%. Chitosan A, stored at 4°C for later use. After testing, the degree of deacetylation of the monocarbo...

Embodiment 2

[0040] Weigh 4.0g of chitosan with a viscosity-average molecular weight of 800,000 and a deacetylation degree of 85% and place it in a 4% (v / v) dilute acetic acid solution at a bath ratio of 1:25 (w / v), stir at 60°C Dissolve in 1 hour, cool to 25°C and add 15mL of mixed acid (V 浓硝酸 :V 浓磷酸 =2:1), then add sodium nitrite with a mass volume ratio of 0.014g / mL to the mixed acid in a light-proof airtight container, and slightly shake it at 25°C for 3 hours, and immediately add 230mL of absolute ethanol after the reaction The oxidation reaction was terminated, the oxidation product was precipitated with acetone, filtered under reduced pressure until the pH of the filtrate was about 6, washed with absolute ethanol, dried in vacuum and refined to obtain a yellow single carboxyl shell with a molecular weight of 110,000 and a carboxyl degree of 40.36%. Glycan B, stored at 4°C for later use. After testing, the degree of deacetylation of the monocarboxychitosan B obtained in this exampl...

Embodiment 3

[0042] Weigh 4.0g of chitosan with a viscosity-average molecular weight of 800,000 and a deacetylation degree of 85% and place it in a 4% (v / v) dilute acetic acid solution at a bath ratio of 1:25 (w / v), stir at 60°C Dissolve in 1h, cool to 25°C and add 21mL of mixed acid (V 浓硝酸 :V 浓磷酸 =2:1), then add sodium nitrite with a mass volume ratio of 0.014g / mL to the mixed acid in a light-proof airtight container, and slightly shake it at 25°C for 8 hours, and immediately add 242mL of absolute ethanol after the reaction Terminate the oxidation reaction, the oxidation product is precipitated with acetone, vacuum filtered until the filtrate pH is about 6, washed with absolute ethanol, vacuum dried and refined to obtain a dark yellow single carboxyl shell with a molecular weight of 60,000 and a carboxyl degree of 53.57%. Glycan C, stored at 4°C for later use. After testing, the degree of deacetylation of the monocarboxychitosan C obtained in this example is 85.3%, the solubility in wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com