Device for replacing traction friction type anchoring hanger rod and method for replacing steel tube arch bridge hanger rod by using device

An anchoring device and friction-type technology, applied in the field of bridge construction equipment, can solve the problems of high construction cost, steel structure arch rib and coating damage, complicated construction procedures, etc., and achieve low construction cost, high work efficiency, and easy standardized construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

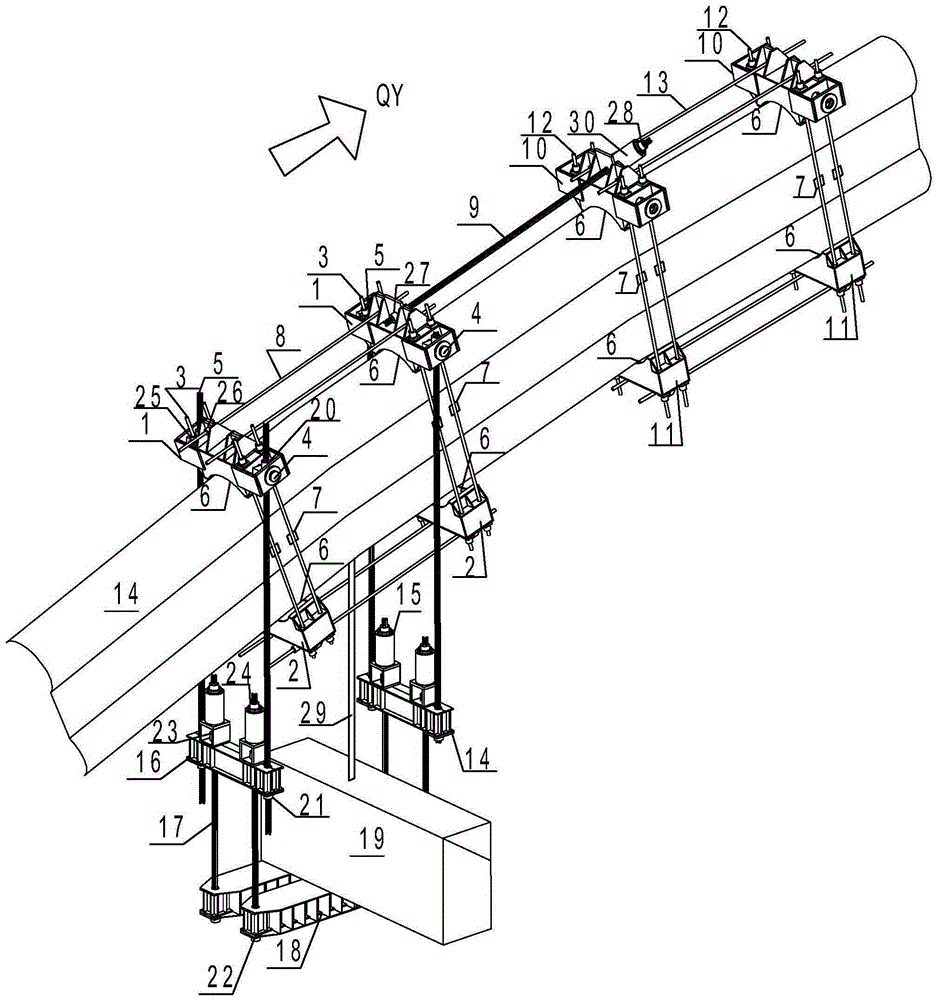

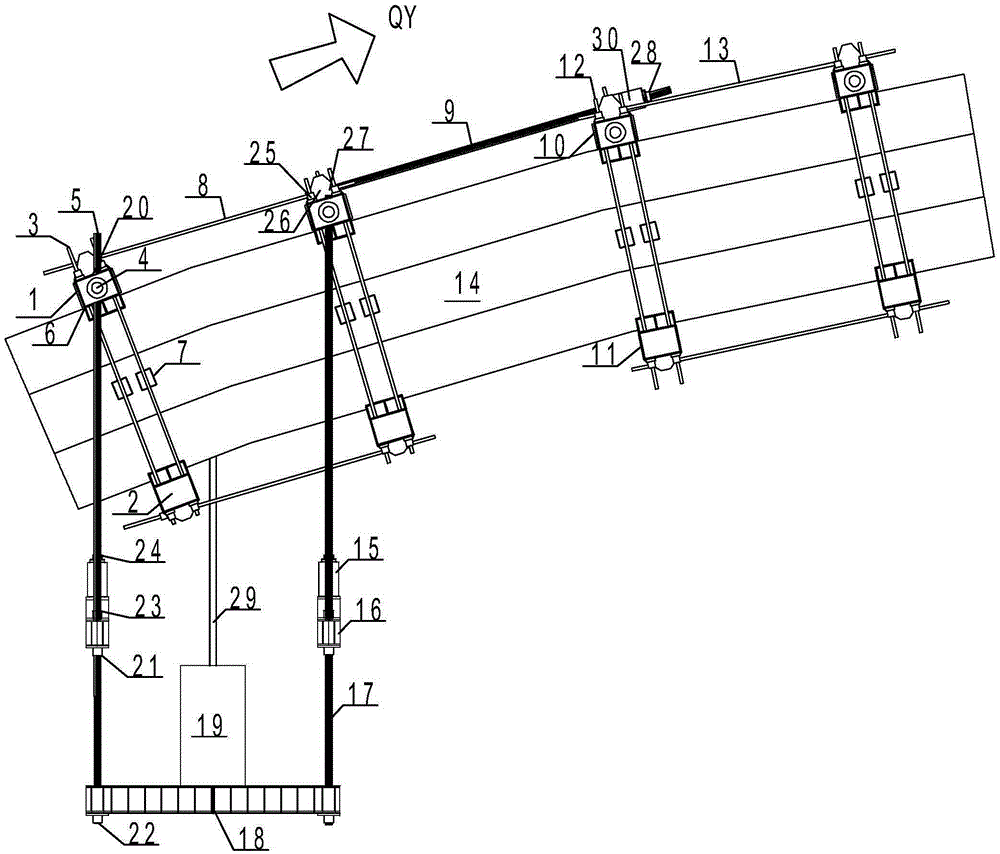

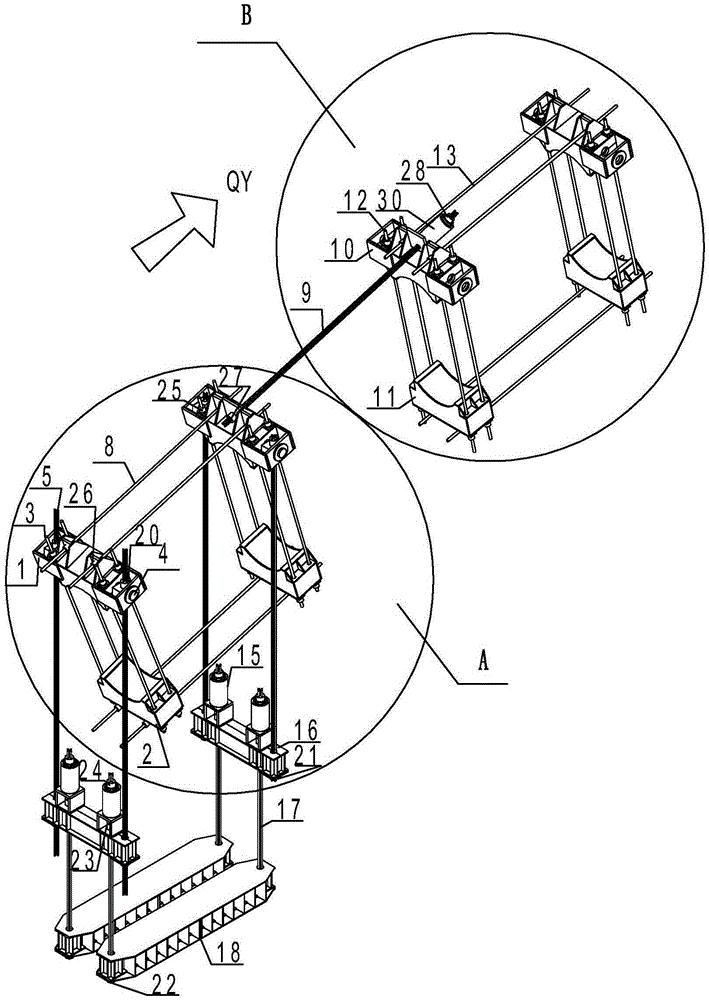

[0049] A traction friction type anchor boom replacement device, such as figure 1 , 2 As shown, the device for replacing the traction friction anchor boom includes steel strand fixed end anchors I, II, III, steel strand tension end anchors I, II, upper conversion beam 16, upper steel strand 5 1. In addition to the lower steel strand wire 17 and the lower joist 18, it also includes a traction friction anchorage arch anchorage anti-skid system installed on the arch bridge arch of steel pipe concrete;

[0050] like image 3 , Figure 4 As shown, the traction friction anchoring arch anchoring anti-skid system consists of a traction cable 9, a traction cable fixed end anchor 27, a traction cable tension end anchor 28, a horse-riding upper clamping device I1, a horse-riding lower clamping device Ⅰ2, rotary spreader 4, pre-tightened threaded steel Ⅰ3, tie rod Ⅰ8, saddle-style upper clamping device Ⅱ10, saddle-riding lower clamping device Ⅱ11, pre-tightened rebar Ⅱ12, tie rod Ⅱ13 、...

Embodiment 2

[0056] A method for replacing the suspension rod of a steel pipe arch bridge, which is a method for replacing the suspension rod of a steel pipe arch bridge using the device for replacing the traction friction anchor suspension rod described in Embodiment 1, and it includes the following steps:

[0057] A. Install the device for replacing the traction friction anchor boom: (see Figure 1-Figure 6 )

[0058] A1. The steel pipe arch 14 is longitudinally symmetrical to the original suspender 29 and the traction friction anchoring arch anchoring anti-skid system is installed on the steel pipe arch 14:

[0059] The traction friction anchoring arch anchoring anti-skid system consists of a traction cable 9, a traction cable fixed end anchor 27, a traction cable tension end anchor 28, a horse-riding upper clamping device I1, a horse-riding lower clamping device I2, a rotating Type spreader 4, pre-tightened rebar Ⅰ3, pull rod Ⅰ8, saddle-type upper clamping device Ⅱ10, equestrian-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com