Turbine steam seal clearance adjustment method

A technology of steam seal clearance and adjustment method, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc. It can solve the problems of complicated process, inability to measure, and burrs on the back arc of the steam seal, so as to achieve simple process, convenient operation, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0029] Examples.

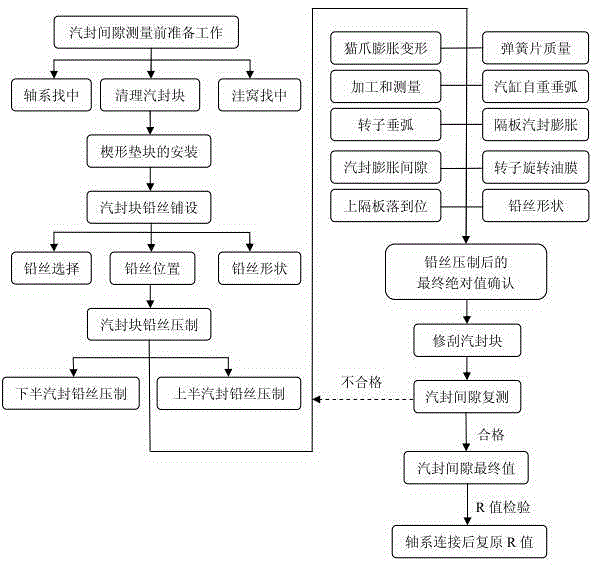

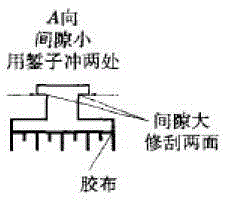

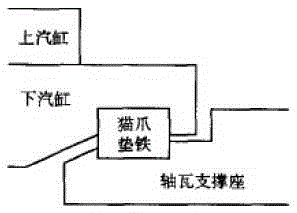

[0030] See Figure 1 to Figure 6 The method for adjusting the gap of the steam turbine seal in this embodiment adopts the method of pressing the lead wire in equal divisions on the circumference. The gap between the lower half of the cylinder and the horizontal joint surface is measured by a feeler gauge, and the gap of the other parts of the steam seal is glued to the corresponding specifications of the lead wire. Put it on the steam seal tooth, the end is fixed, hoist the rotor in the working position, the lead wire stuck on the steam seal tooth is pressed out a groove mark, hang out the rotor, and measure the remaining lead wire groove mark with the seal gap measurement ruler Part of the thickness, this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com