Method for measuring local geometric initial defects of steel member with box-shaped section

A technology of local geometry and measurement method, applied in the field of structural engineering steel structure, can solve the problems of unsuitable construction site measurement, unsuitable for on-site measurement, and low operability, etc. The method is simple and practical, easy to prepare, and reduces errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

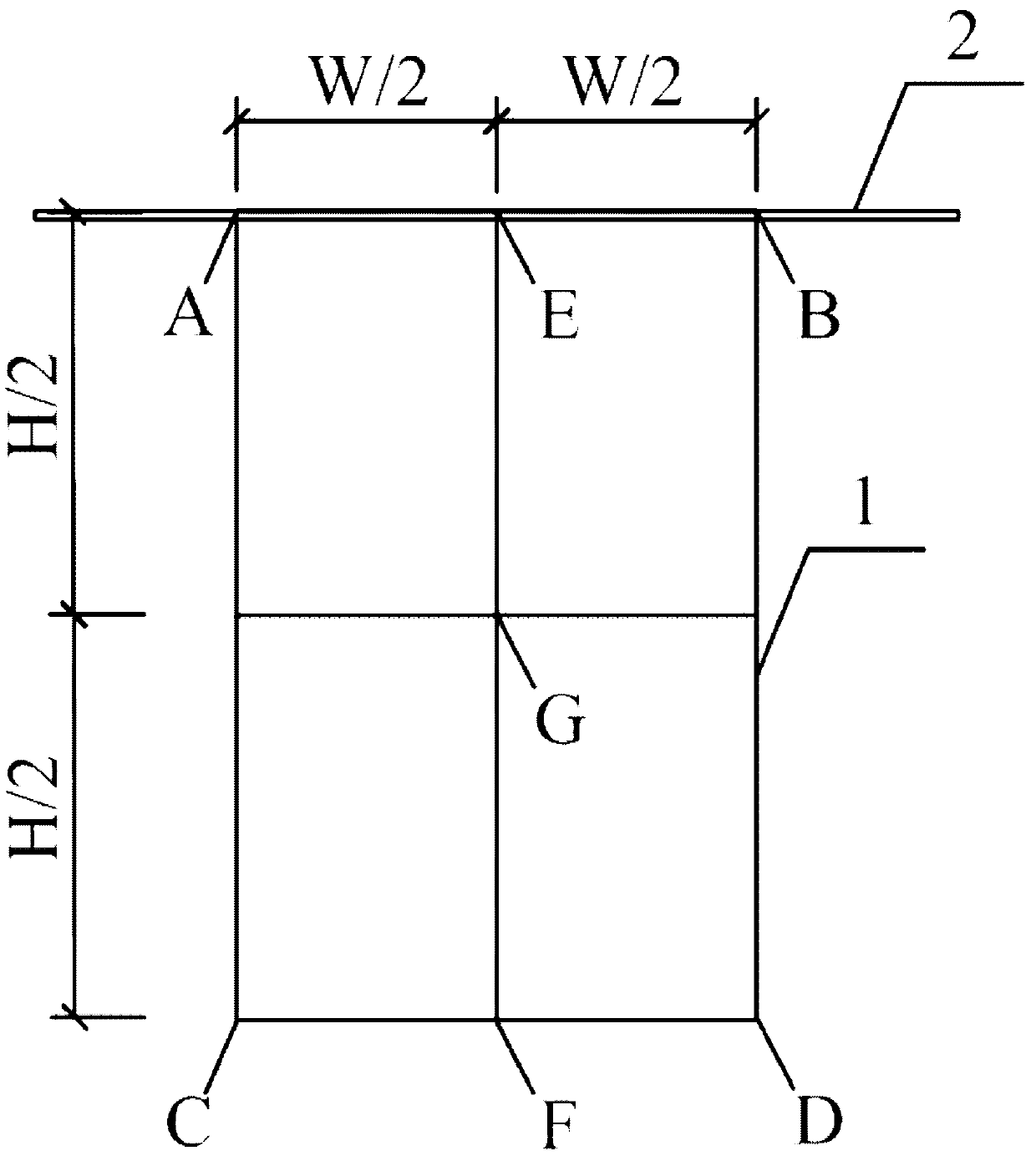

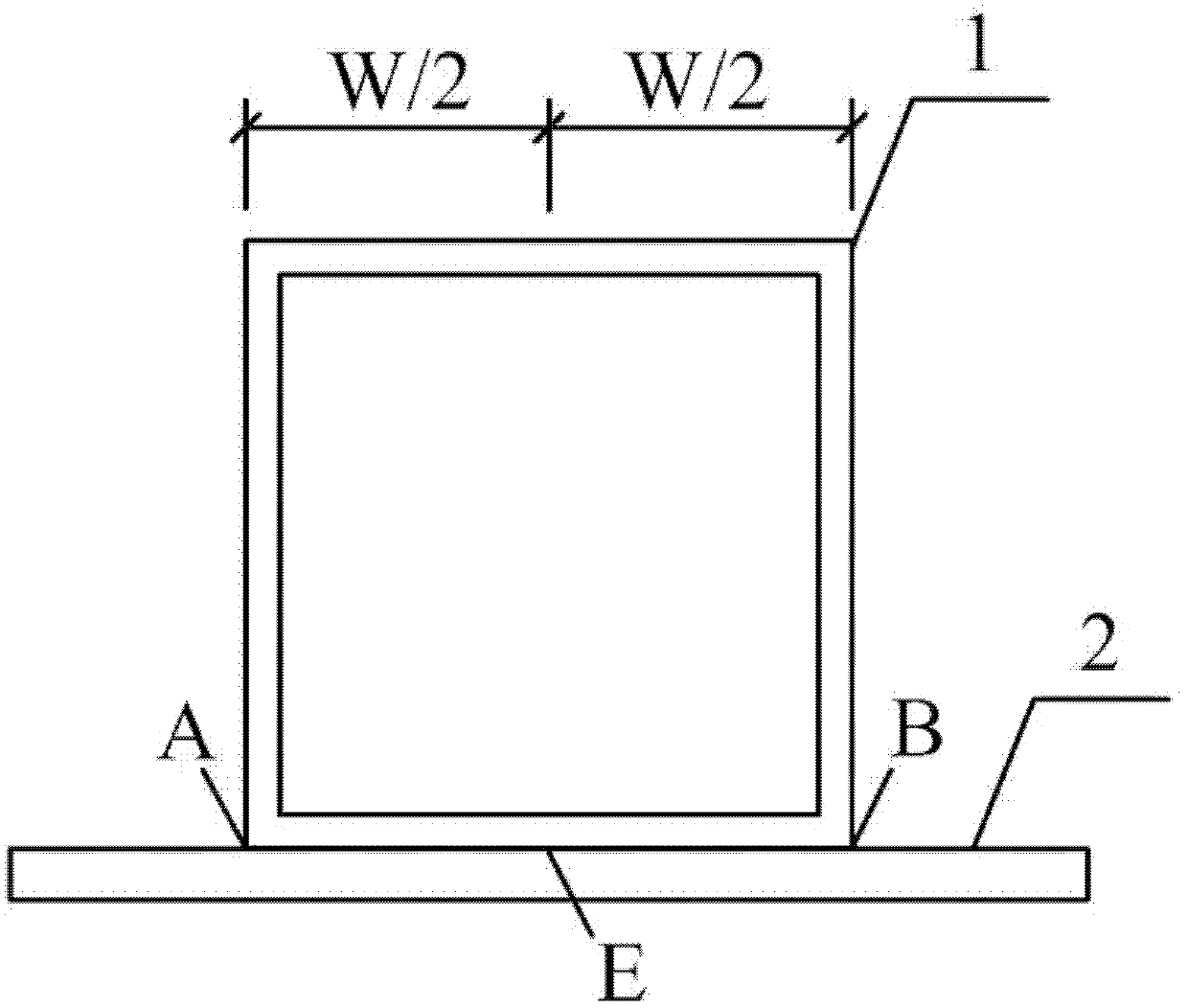

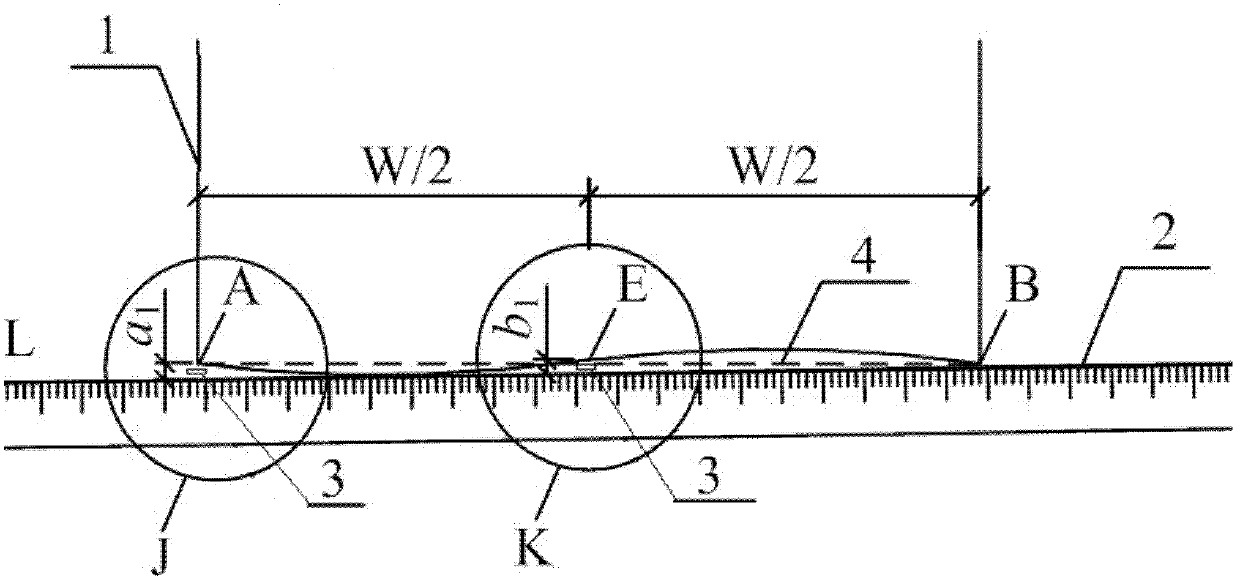

[0049] In this embodiment, steel rulers and feeler gauges are used to measure local geometric initial defects of box-section steel members, and a total of 4 members are measured. Among them, the height H of the four steel plates of the numbered B-1 component is 302.3mm, and the width W is 241.6mm, and the height H of the four steel plates of the numbered B-2 component is 502.6mm, and the width W is 433.9mm. The height H of the 4 steel plates of the member numbered B-3 is 603.0mm, and the width W is 522.3mm. The height H of the 4 steel plates of the member numbered B-4 is 802.4mm, and the width W is 682.3mm. Using a steel ruler with a specification of 1m and a feeler gauge with a specification of 0.1mm, the measurement steps are:

[0050] Step 1: Fix the box-section steel component to be tested, referred to as component 1, vertically on the ground, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com