Rhombus plug gauge processing method

A processing method, diamond-shaped technology, applied in the processing field of diamond-shaped plug gauges, can solve problems such as lack of precision, high processing difficulty, and scrapped workpieces, so as to reduce processing difficulty, ensure processing accuracy and product quality requirements, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

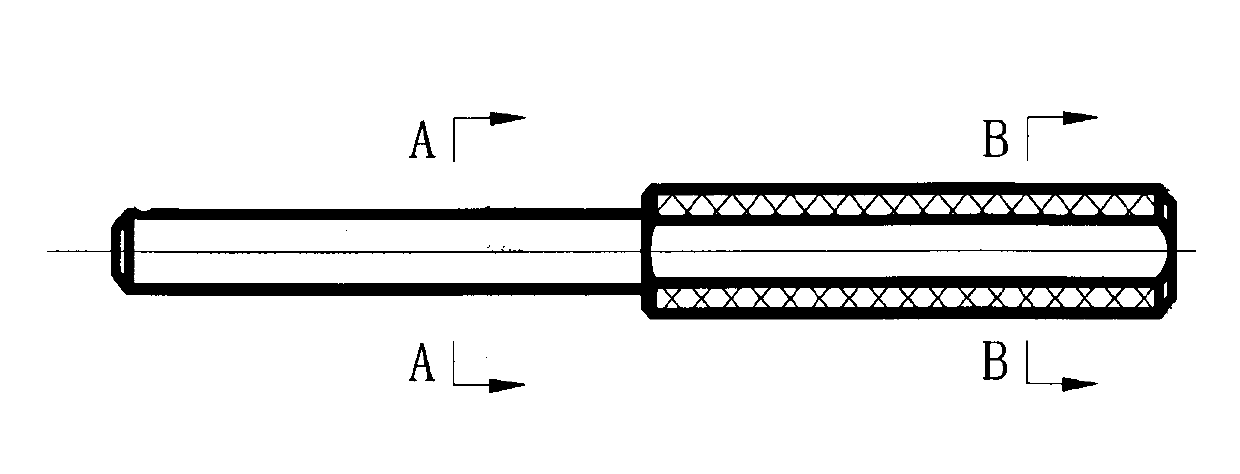

[0027] Such as Figures 4 to 6 As shown, taking a diamond-shaped plug gauge with a handle part diameter of Φ8mm, a diamond-shaped side length of 4.8mm in the working part, and a diamond-shaped angle of 82° as an example, the processing method includes the following specific steps:

[0028] (1) Preparation of materials: select forgings with intact materials, no cracks, and no blisters;

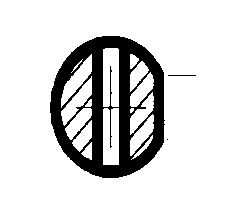

[0029] (2) Turning process: the working part and the handle part are pushed into shape, first calculate the lengths of the two diagonals of the rhombus of the working part as 7.32mm and 6.36mm respectively, and carry out the outer circle to Φ8 according to the length of the longest diagonal .5mm, knurling on the handle part, such as Figure 7 shown;

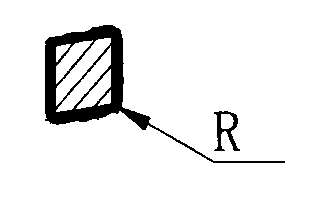

[0030] (3) Milling process: Milling the marked surface, that is, the flat part of the B-B section, is used to write the product specification, drawing number, year, month, etc., and then according to the size requirements of the diamond plug gau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com