Ballastless track plate seam depth non-destructive detection method and equipment based on vibration

A ballastless track and non-destructive testing technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve problems that are difficult to meet the actual detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

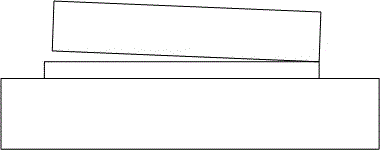

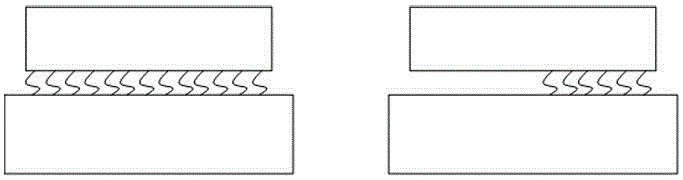

[0056] like Figure 9 , a vibration-based non-destructive detection method for the separation depth of ballastless track slabs. Departure depth detection, the detection method includes the following steps in order:

[0057] S1, fixing the excitation recording element on the track plate to be detected;

[0058] S2. Using an excitation device to vibrate the track plate, so that the track plate generates a vibration signal;

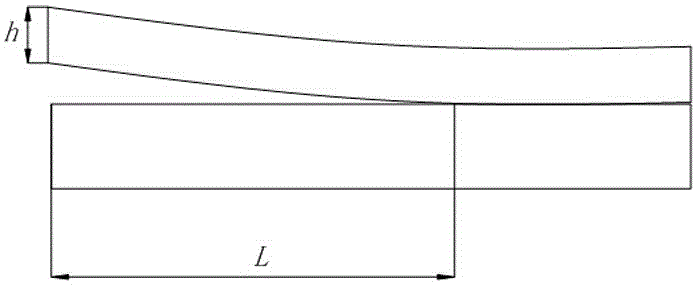

[0059] S3. Obtain the first-order natural frequency f in the vibration signal on the spectrum diagram obtained by the excitation signal processing element 1 or the second-order natural frequency f 2 , and the depth of the track slab gap is obtained by the following formula: Among them, L is the depth of the track slab, ρ is the density of the track slab, h is the thickness of the track slab, E is the dynamic elastic modulus of the track slab, A is the area of the vibration section of the track slab, and I is the moment of inertia of the track slab sec...

Embodiment 2

[0070] This embodiment is further limited on the basis of Embodiment 1, as a further technical solution of the vibration-based non-destructive detection method for the separation depth of ballastless track slabs:

[0071] In order to simplify the calculation of the above formula and improve the detection accuracy of the gap, the value of E or the value of E / ρ is obtained in the following way:

[0072] E=E c / 0.83, where E c is the elastic modulus of track slab concrete, and 0.83 is the corrected value obtained through data fitting. For C55 concrete, it can be 35.5GPa; for C60 concrete, it can be 36.0GPa;

[0073] As a technical solution that can be directly tested on site:

[0074] Among them, f d is the natural frequency f on the spectrogram 1 The reflection frequency corresponding to the longitudinal wave resonance in the corresponding period is also called the excellent frequency.

[0075] Since different track plates have different E values and ρ values, f d It i...

Embodiment 3

[0081] This embodiment further defines the device on the basis of Embodiment 1: As a further technical solution of the vibration-based ballastless track plate separation depth non-destructive testing device, the data connection is a wire electrical connection, wireless Any of the signal data connections. The above data connection forms can be freely selected according to the detection conditions or cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com