Method for inspecting complex space integration position of steering knuckle type part

An inspection method and steering knuckle technology, applied in the inspection field of complex space comprehensive location, can solve the problems of inability to realize inter-process inspection, low requirements on the skill quality of operators, low inspection efficiency, etc., and meet the requirements of difficult measurement and worker quality. The effect of not high and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

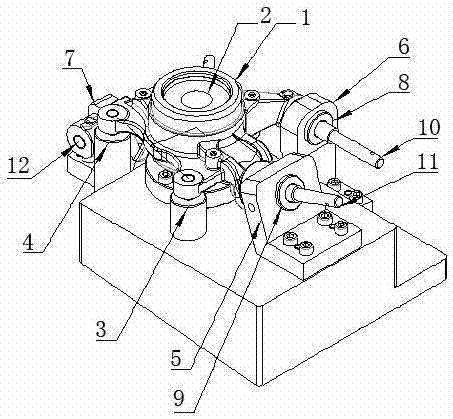

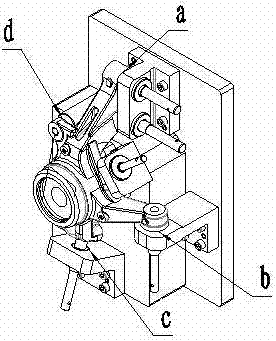

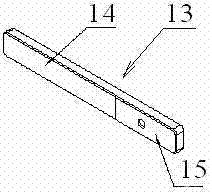

[0025] Combine figure 1 , figure 2 with image 3 , The inspection method of the complex spatial integrated position of the steering knuckle parts of the present invention, firstly, the main positioning hole of the inspected part 1 is correspondingly placed on the positioning shaft 2 fixedly connected to the base, and the other positioning of the inspected part 1 The holes correspond to the positioning pins fixed on the base 3 and positioning pins 4 on, so as to realize positioning axis 2, positioning pin 3 and positioning pins 4 Determine the only position of the inspected part 1 to fix the inspected part 1. If necessary, a movable pressing plate can be used to press the inspected part; secondly, the latch 10. Bolt 11 and latch 12 Insert the bushes separately 8 and bushing 9 in the guide hole, bolt 10. Bolt 11 and latch 12 is divided into the support on the base of the fixed connection 5. Support 6 and support 7 on; latch 10. Bolt 11 and latch 12 Slide in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com