Adjustment method for pinch roll of double-sided shears

An adjustment method and technology of pinch rollers, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem that the installation and adjustment accuracy of pinch rollers is difficult to achieve the desired effect, influence, installation and adjustment accuracy, pinch roller deviation, etc. problems, to achieve the effect of reducing poor shearing quality, avoiding deviation, and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment this method is described further:

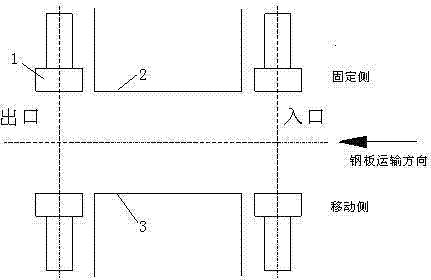

[0015] See attached figure 1 , in the schematic diagram of pinch roller distribution, there are 8 pinch rollers 1 (16 for some double-sided shears), of which there are two on the fixed side of the entrance (one on the upper and one on the lower), and two on the moving side of the entrance (one on the upper and lower) 1 for each), two on the fixed side of the exit (1 each on the upper and lower sides), two on the moving side of the exit (1 each on the upper and lower sides); the double-sided shear racks are divided into fixed side racks 2 and mobile side racks 3 .By moving the side frame 3, the width of the two frames can be adjusted between 1400mm-3700. The steel plate transportation direction is from the entrance to the exit.

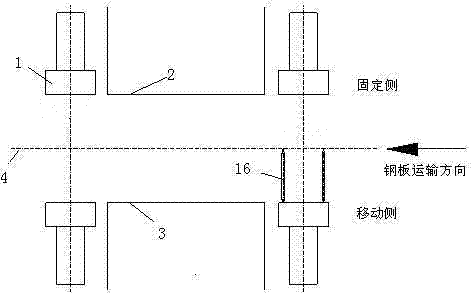

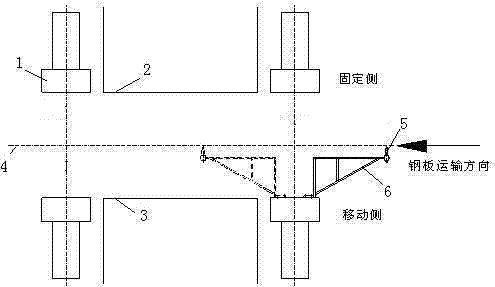

[0016] See attached figure 2 , in the schematic diagram of parallelism adjustment, pull a steel wire 4 parallel to the trimming scissors betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com