Setter plate applied to low-temperature co-sintering ceramic sintering

A technology of low temperature co-fired ceramics and setter plates is applied in the field of setter plates sintered by low temperature co-fired ceramics. Short, optimized electrical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

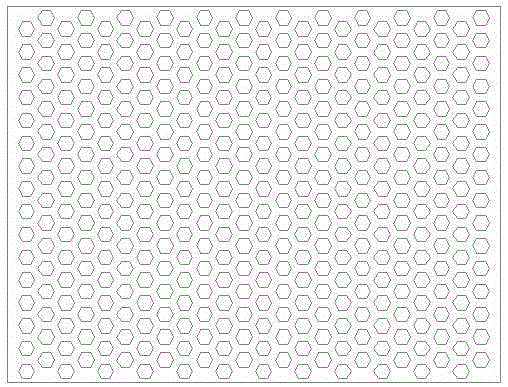

[0014] Referring to the accompanying drawings, the setter plate used in the sintering of low-temperature co-fired ceramics is a flat plate with a cavity structure; it is formed by high-temperature ceramics, and the specific implementation method includes the use of conventional multi-layer ceramic manufacturing processes, and the use of conventional blanking and grinding processes; The surface roughness is less than 1.6, the surface flatness is less than 15μm, and the upper and lower flatness is less than 1°; it can meet the sintering of existing types of low-temperature co-fired ceramics.

[0015] The setter plate is a flat plate with a cavity structure, and a cylindrical cavity with a plane geometric figure is formed on the surface, and the design is simple, such as a grid-like columnar cavity, a circular column-like cavity, and an irregular figure-like columnar cavity, etc. , The minimum wall thickness between the cavities is 0.3mm.

[0016] The setter plate has a simple st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com