Flexible checking implement for large complicated carved punched thin-wall workpiece

A technology for complex curved surfaces and thin-walled parts, applied in the field of flexible inspection tools, can solve the problems of only applicable inspection tools, long production cycle, complex workpiece shape, etc., achieve good accuracy consistency, improve processing quality, and meet process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

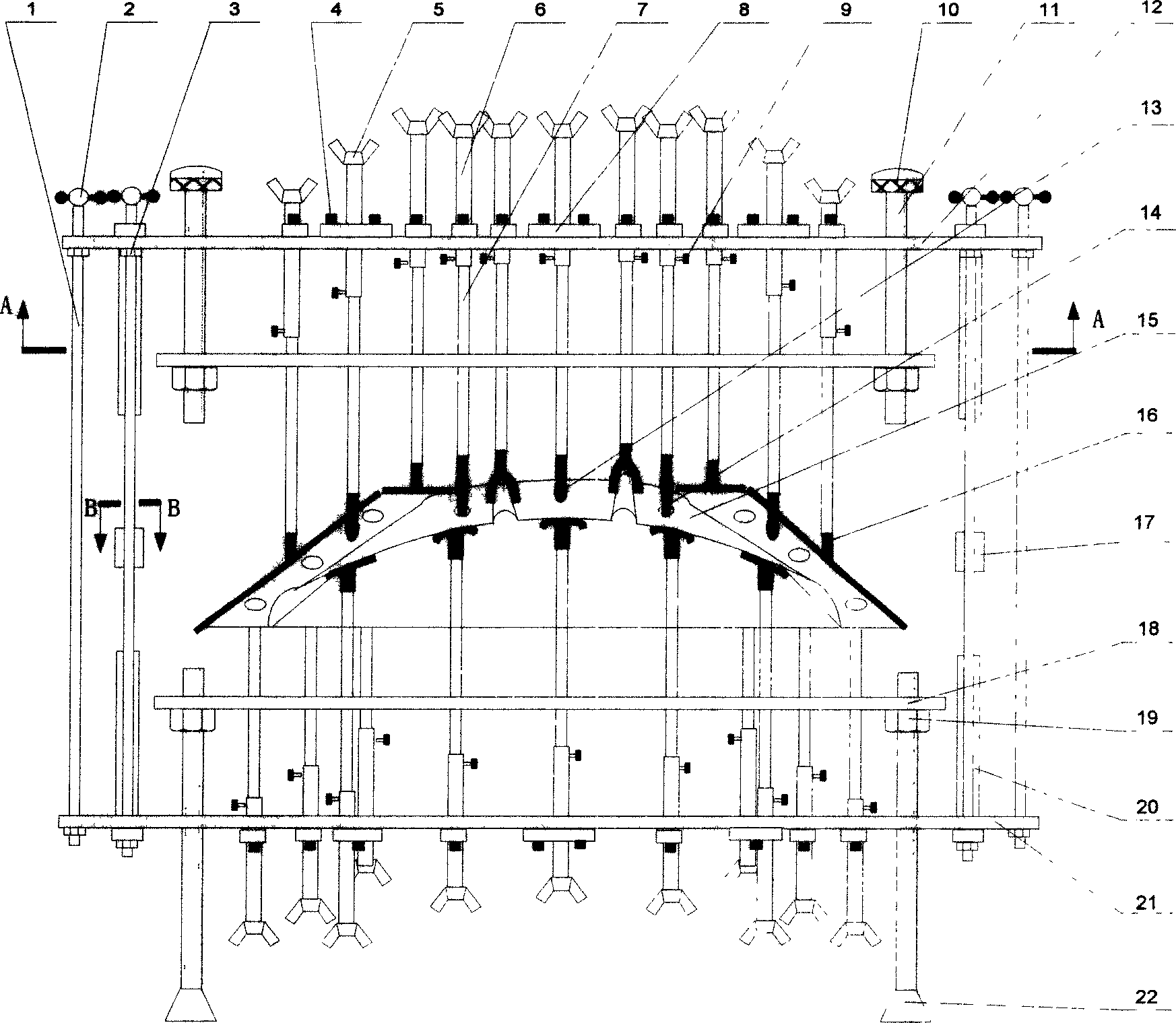

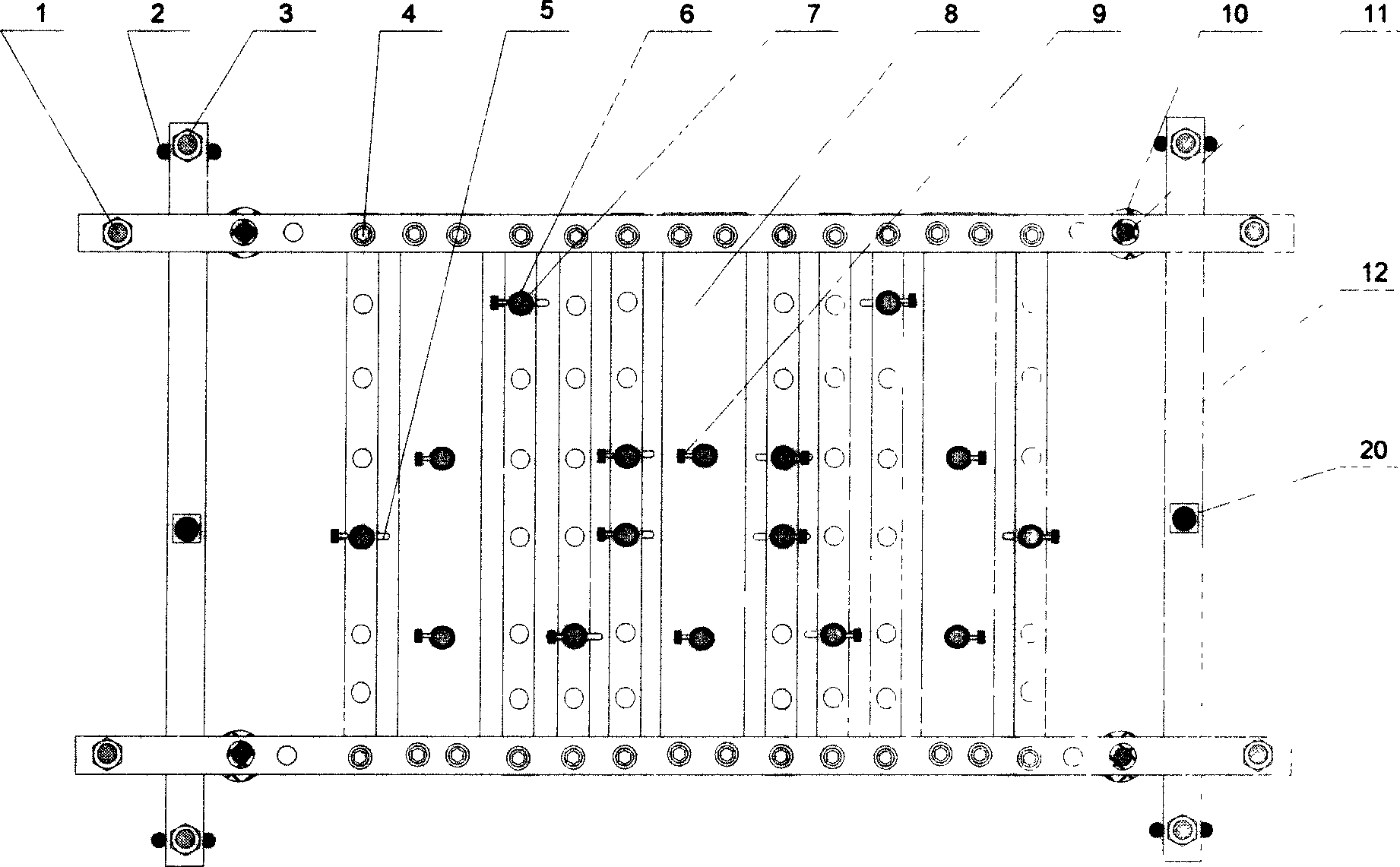

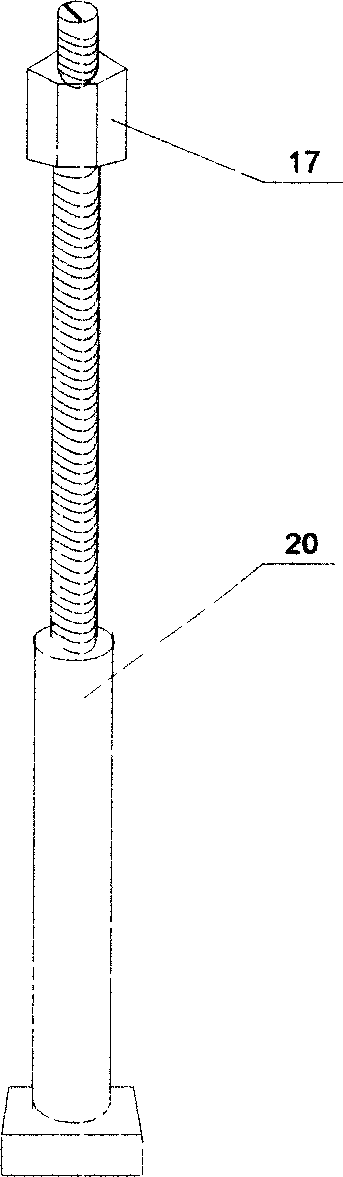

[0024] Such as figure 1 As shown, the present invention is made up of two sets of symmetrically arranged frames up and down. The uppermost and the lower ends are two "well" shaped frames, i.e. the upper frame 12 and the lower frame 21. Eight of the two frames There is a through hole at the end point, and the upper frame body 12 is fixedly connected with the lower frame body 21 with the hex nut 3 through the through hole with a long-legged screw rod 1 with a handle 2 . There are two square blind holes in the center of the two width directions of the upper and lower "well" frame bodies, which are respectively used to fit the internally threaded sleeve 20 with a square prism at the bottom and a hexagonal prism in the middle. The double-ended adjusting screw 17 of the body penetrates into the middle of the upper and lower two internally threaded sleeves 20; threaded holes are evenly and symmetrically opened in the middle of the two long sides of the upper frame body 12 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com