Leakage control device for ball valve telescopic joint of pump storage group

A technology for pumped storage units and leak-proof devices, which is applied to mechanical equipment, flange connections, passing components, etc., and can solve problems such as no obvious improvement, inability to fully open, and increased bolt tightening torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

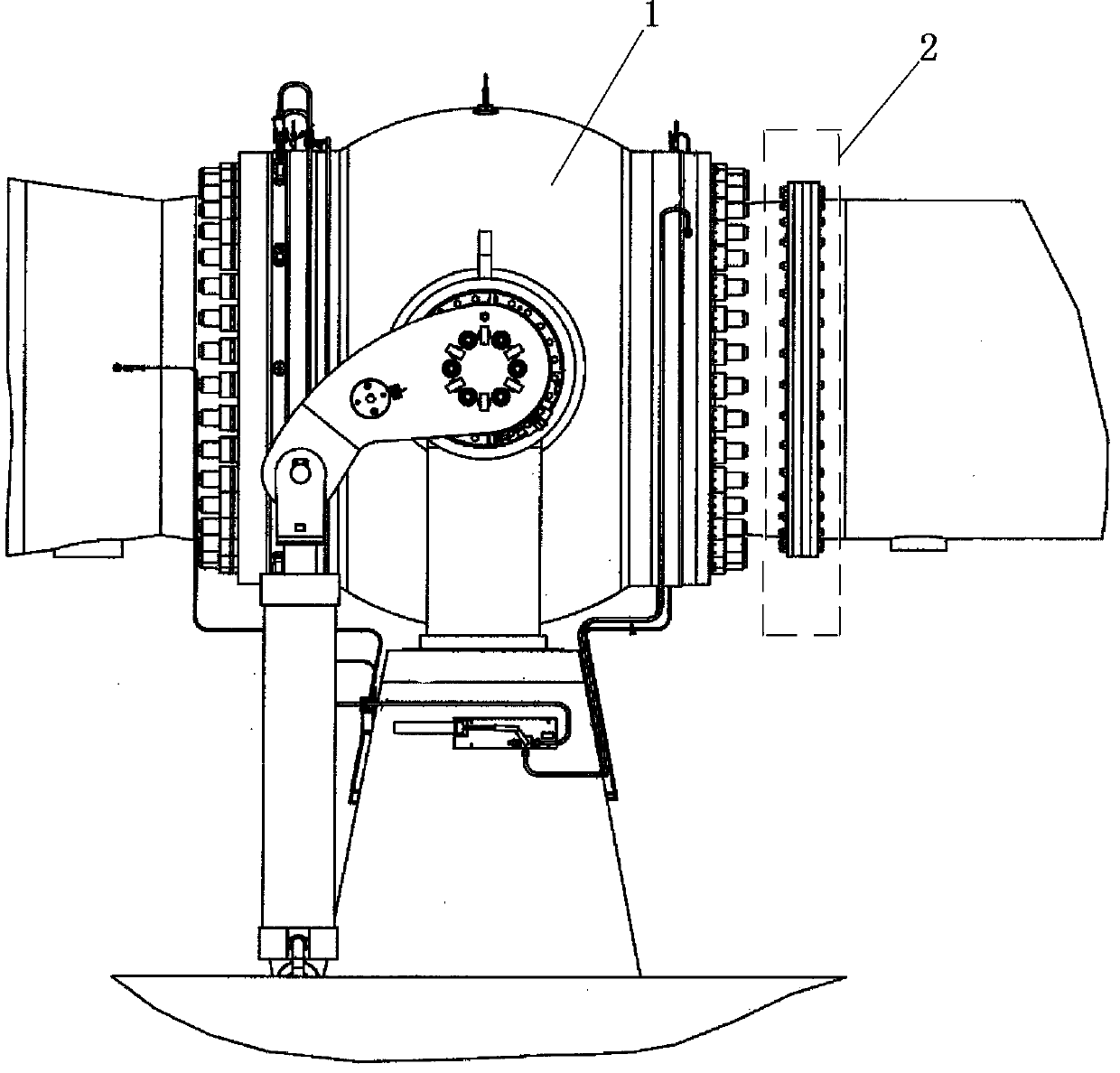

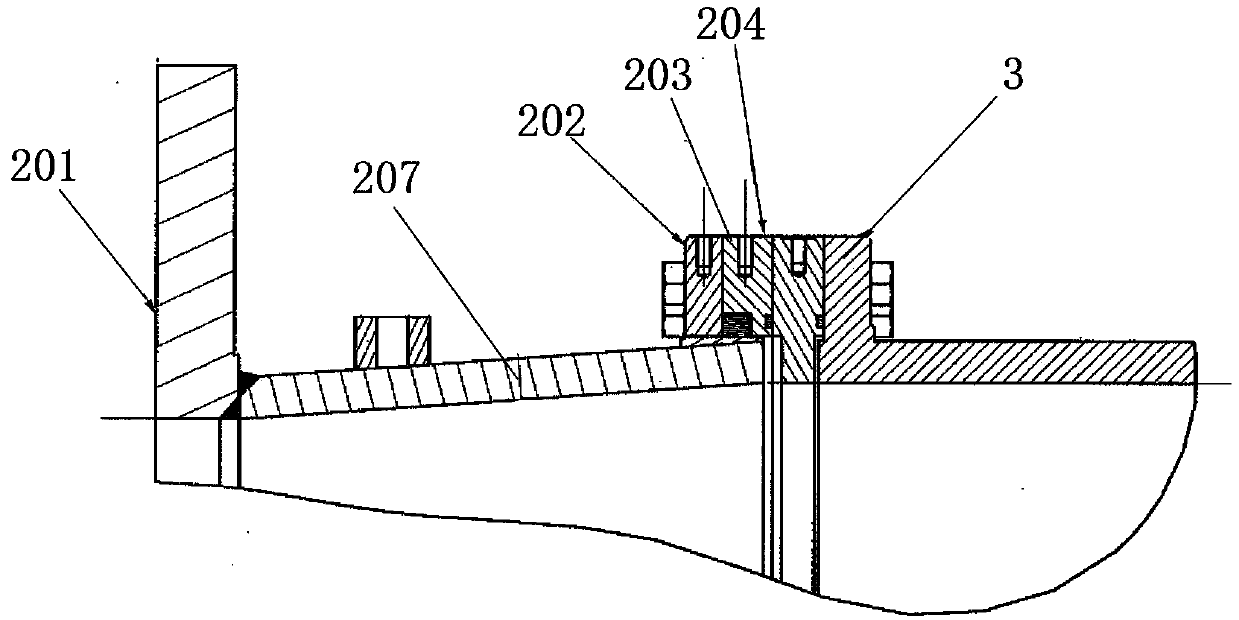

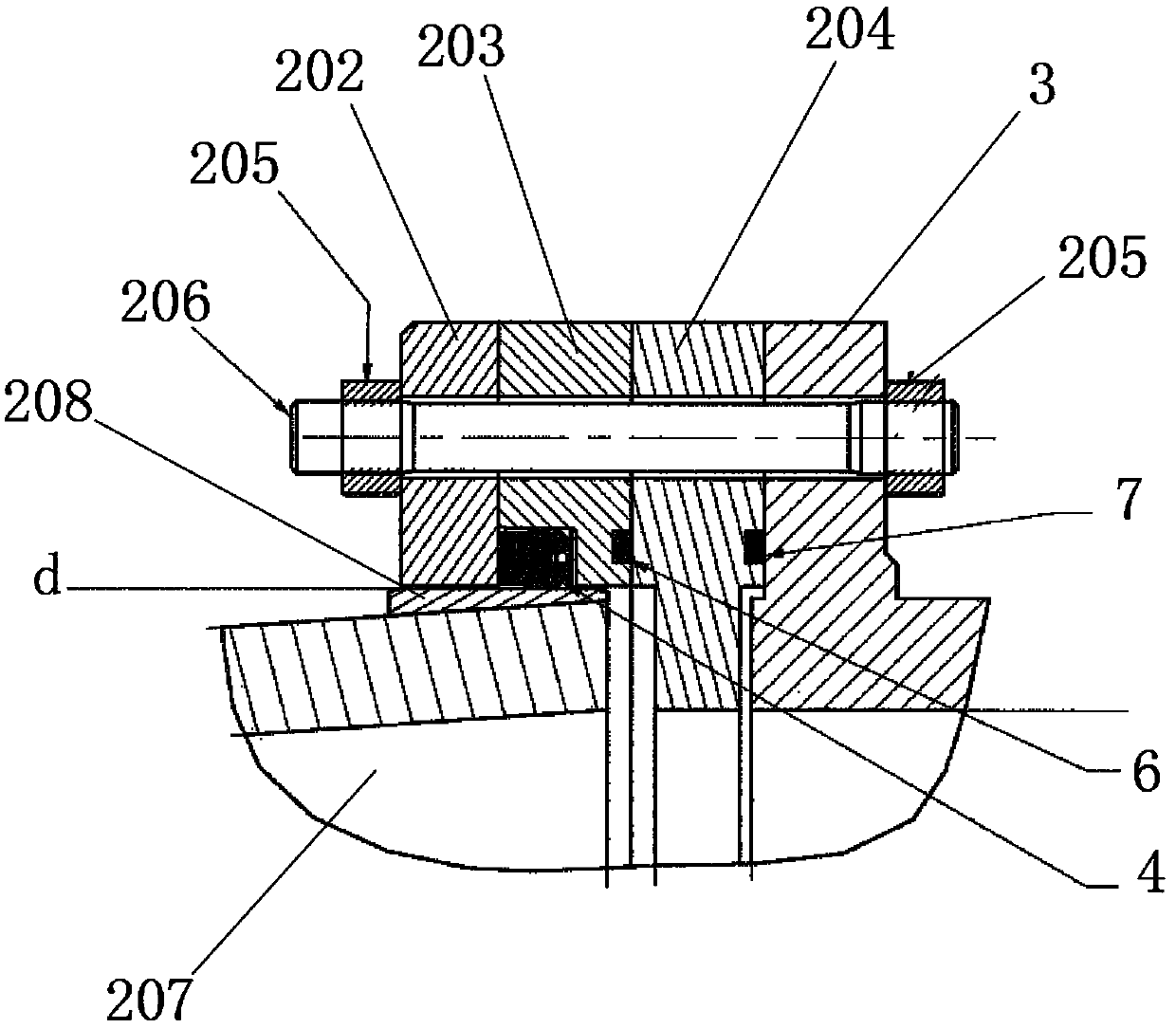

[0019] Embodiment 1: A leak-proof device for ball valve expansion joints of pumped storage units, see figure 1 , is an improvement made for the expansion joint downstream of the ball valve 1. The expansion joint 2 downstream of the ball valve is connected by the pipe flange 3 and the transition pipe 207 and a sealing structure is provided. Depend on figure 2 and image 3 It can be seen from the figure that the third movable ring 204, the second movable ring 203 and the first movable ring 202 are sequentially attached to the pipe flange 3, and the above four-layer structures are fixed through bolts 206, and nuts 205 are respectively installed at both ends of the bolts 206. Furthermore, an O-ring 8 is provided between the pipe flange 3 and the third movable ring 204 , and an O-ring 7 is provided between the third movable ring 204 and the second movable ring 203 . figure 2 and image 3 Among them, the transition pipe 207 is located inside the second movable ring 203 and the ...

Embodiment 2

[0021] Example 2: see Figure 5 , the content is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that the combined O-shaped seal ring 5 is located at the notch of the horizontal U-shaped seal ring 4 open grooves, and the diameter of the combined O-shaped seal ring 5 is greater than The width of the opening groove of the horizontal U-shaped sealing ring 4. Under the action of water pressure, the combination O-shaped sealing ring 5 will be pressed into the opening groove of the horizontal U-shaped sealing ring 4, so as to keep the horizontal U-shaped sealing ring 4 from deformation. Thereby, the problem that the horizontal U-shaped sealing ring 4 cannot be tightly sealed due to the deformation caused by the weight of the expansion joint can be eliminated. Even if the horizontal U-shaped sealing ring 4 has deformation, the opening groove of the horizontal U-shaped sealing ring 4 cannot be tightly sealed with the equipment. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com