Device and method for filling a container with a carbonated filling product

A filling equipment and carbonation technology, which is applied to the types of packaging items, the use of back pressure perfusion, packaging, etc., can solve the problems of shortening the cleaning cycle and achieve the effect of avoiding the formation of biological thin layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

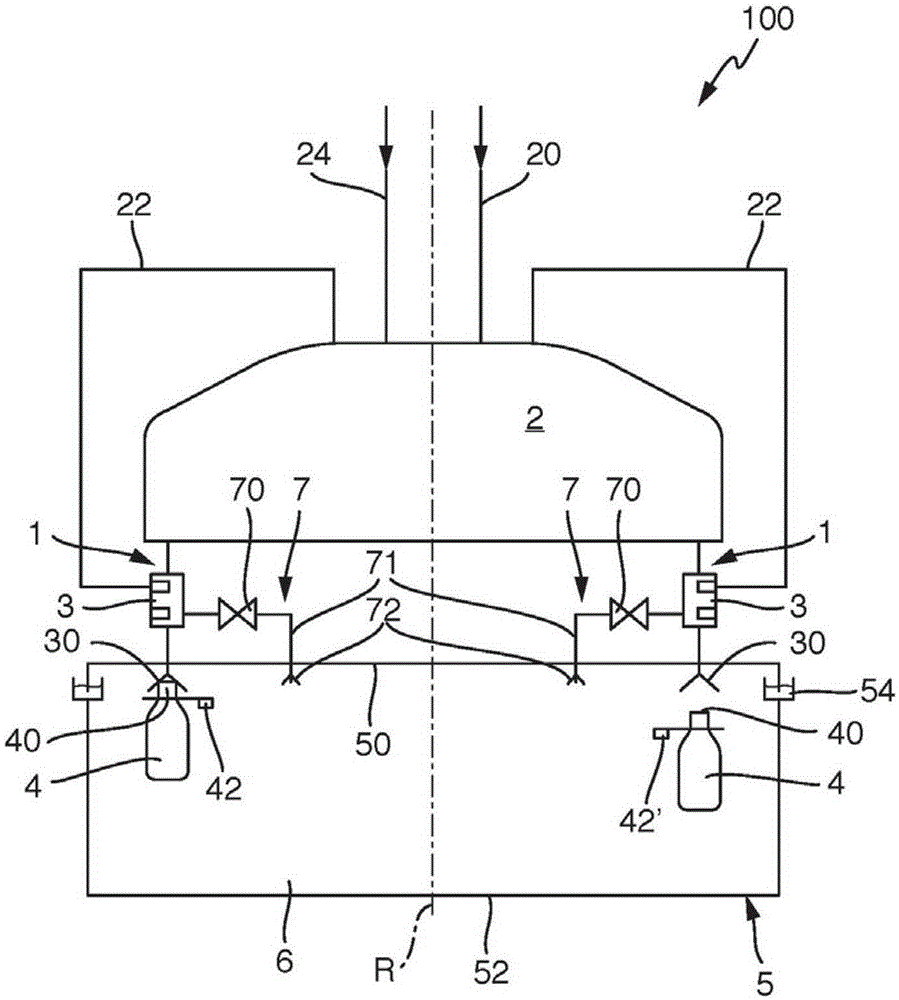

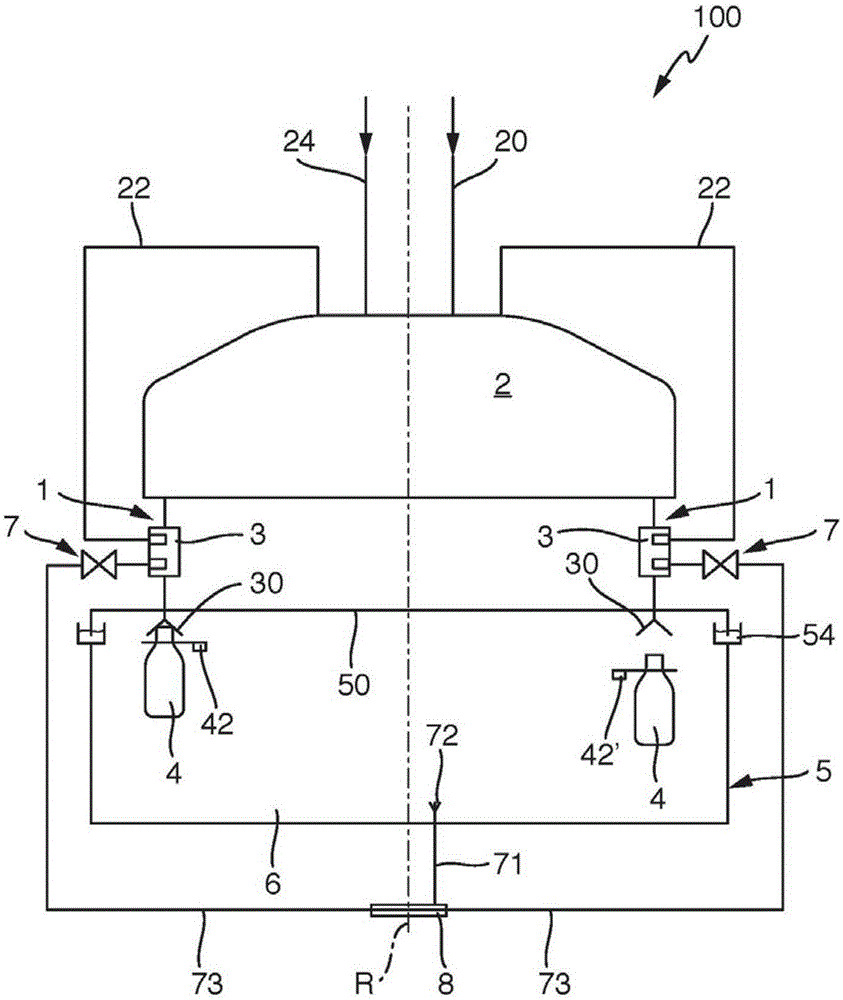

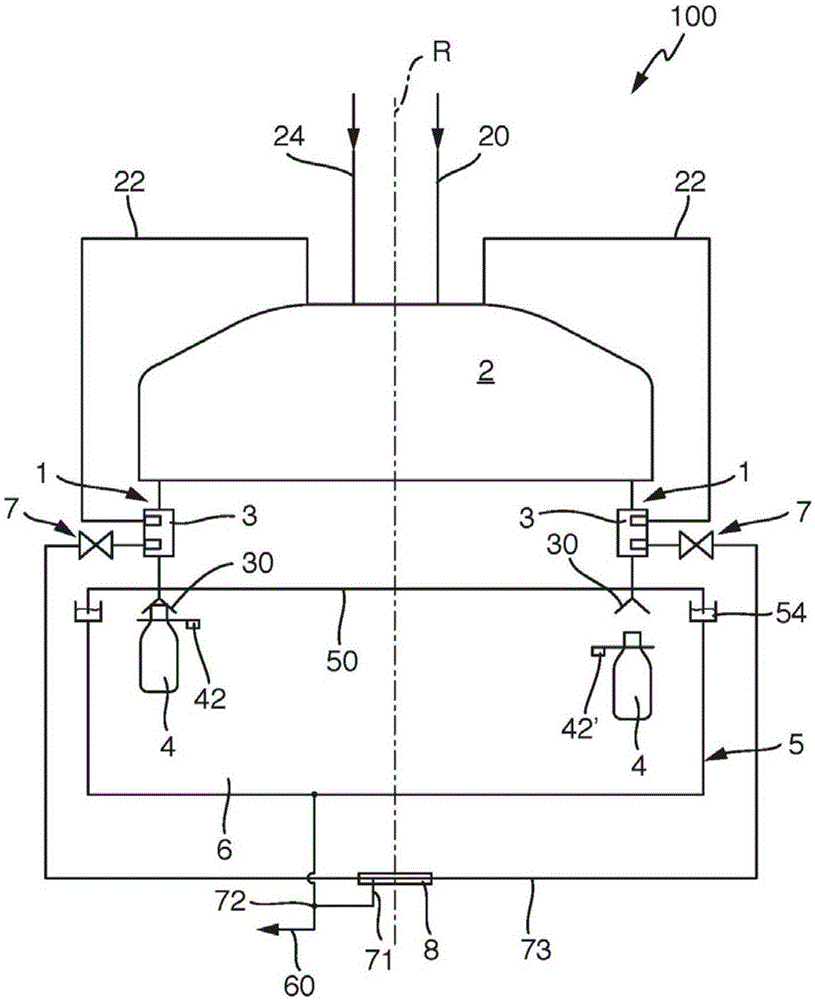

[0028] Preferred embodiments are described below with reference to the accompanying drawings. In this respect, identical, similar or equally acting components are marked with the same reference numerals. In order to avoid repetition, repetitive descriptions of these components are partially omitted in the following description.

[0029] figure 1 A schematic view of a rotary filling machine 100 with a plurality of filling units 1 for filling containers 4 to be filled with a filling product is shown. Via a product feed line 20 , a product tank 2 , for example a schematically shown central tank, is supplied with filling product to be filled into a container 4 to be filled. The canned product to be filled is preferably a carbonated canned product, such as soft drinks, mineral water or beer.

[0030] Since carbonic acid is released from the filled product at atmospheric pressure, the product tank 2 is overpressured by the introduced pressurized gas through the pressurized gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com