Manufacturing method of multi-axial composite base material

A composite substrate and manufacturing method technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem of high initial investment in the production of multi-axial glass fiber products, which affects the rapid development of multi-axial composite products. , the complexity of the structural control system, etc., to simplify the structural design and precision control, improve resource utilization, and reduce the amount of wire used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The steps of the manufacturing method of the multiaxial composite base material in the present invention are:

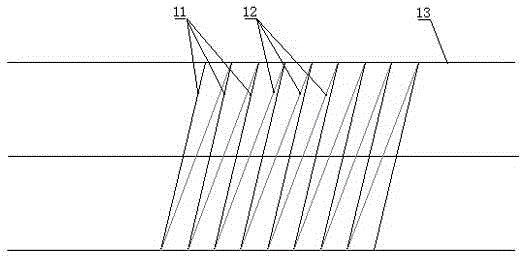

[0040] Step S1 Laying a layer of multi-axial glass fiber yarns: it includes laying a layer of warp yarns and at least two layers of weft yarns, specifically:

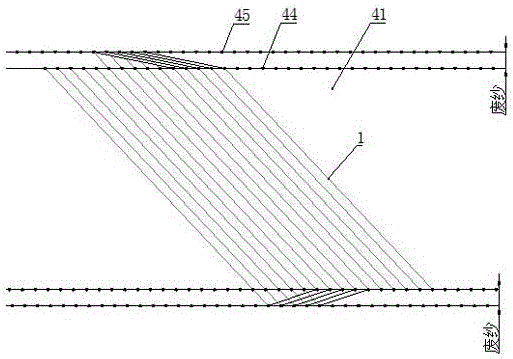

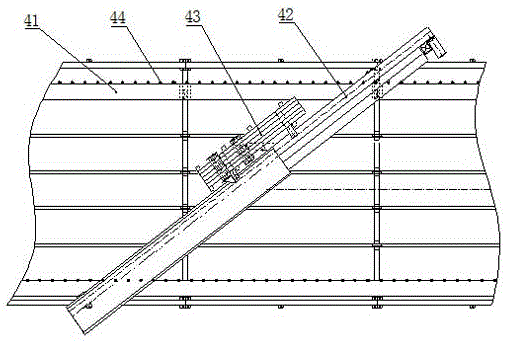

[0041] Lay the weft layer: eg figure 2 As shown, in this method, the multiaxial glass fiber weft yarn layer 11 is laid by a weft laying device group, and the weft laying device group is set according to the number of weft yarn layers, and each weft laying device includes a trolley guide rail installed on the frame across the conveyor belt 41 42, and the weft-laying dolly 43 that can move along the extension direction of the dolly guide rail 42, the both sides of the conveyor belt 1 are evenly distributed with retaining pins 44.

[0042] A layer of glass fiber weft yarn is laid by reciprocating movement of the weft-laying trolley 43 above the conveyor belt 41. After the weft-laying trolley 43 moves f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com