Method for preparing self-packaging of MEMS (micro electro mechanical systems) device based on surface sacrificial layer technology

A sacrificial layer, self-encapsulation technology, applied in the process of producing decorative surface effects, metal material coating process, coating and other directions, can solve the problem of high packaging requirements, achieve high yield, large commercial value and market , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below through specific embodiments and accompanying drawings.

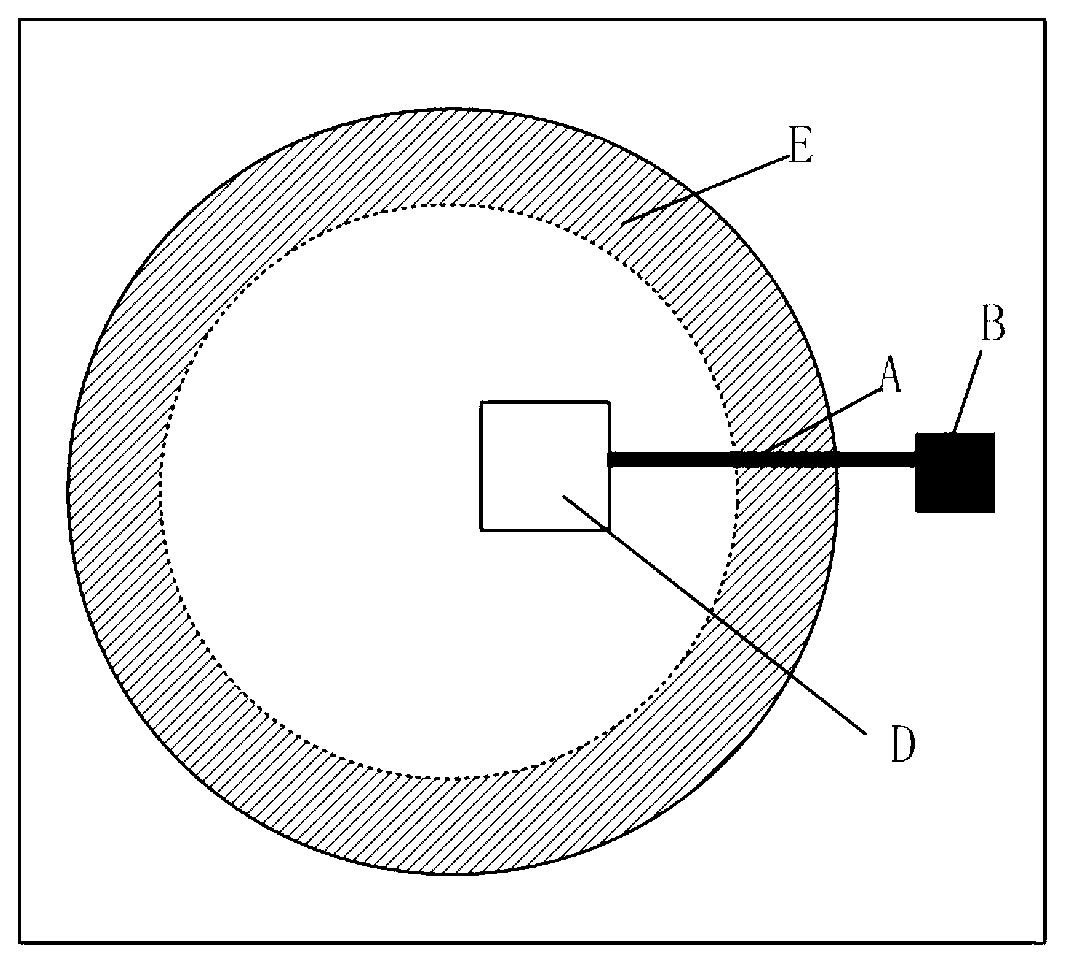

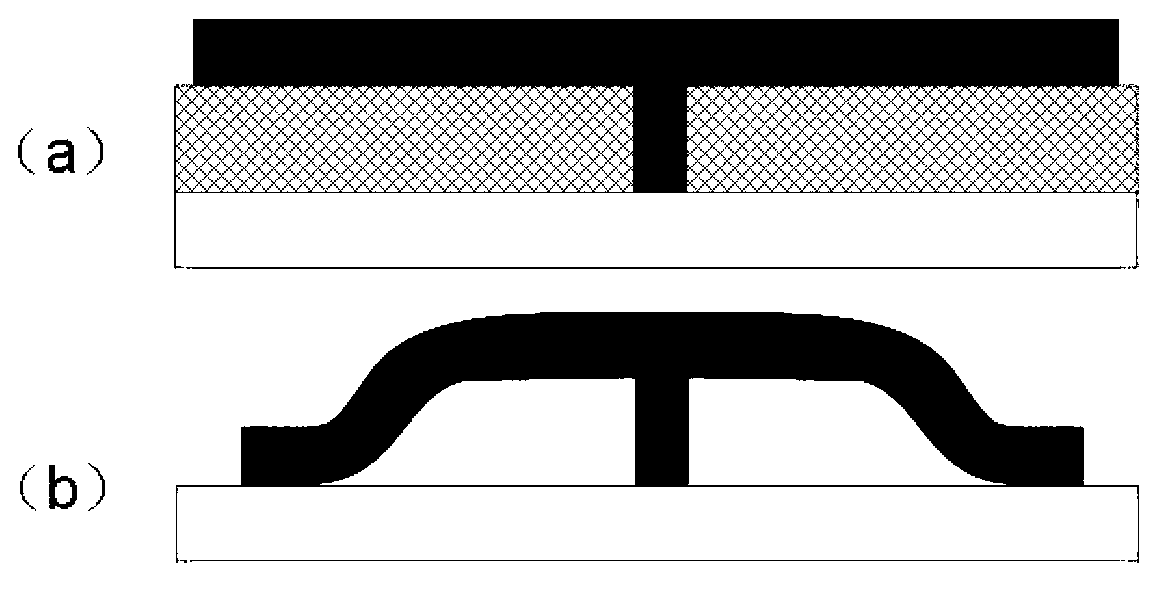

[0043] The infrared chip self-packaging method of the present invention can be applied to MEMS device chips with movable structures processed by surface sacrificial layer integration technology, such as infrared sensors, accelerometers, gyroscopes and other sensors, and actuators such as adjustable capacitance structures. Taking the production of polysilicon / gold dual-material cantilever infrared sensor as an example, the interconnection structure of the capacitive readout method is adopted. The specific process flow is shown in Figure 3, and its description is as follows:

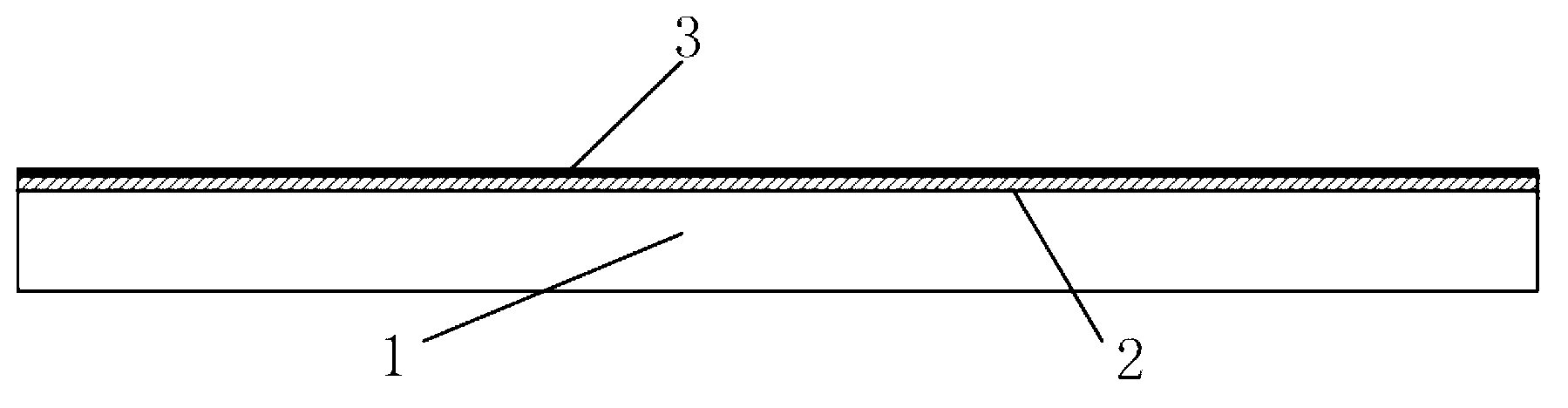

[0044] 1. Preparation sheet: the monocrystalline silicon substrate is used as the substrate 1 of the chip;

[0045] 2. Deposit substrate protection layer, including: LPCVD SiO 2 , with a thickness of That is, the silicon oxide layer 2 in Figure 3(a) is formed; LPCVD Si 3 N 4 , with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com