High-voltage single solid-state lithium ion battery and preparation method thereof

A lithium-ion battery and high-voltage technology, which is applied in the preparation of high-voltage single-solid-state lithium-ion batteries and the field of high-voltage single-solid-state lithium-ion batteries, can solve the problems of complex structure and process, difficulty in large-scale industrial production, etc. Avoid heat generation or rate difference, achieve large-scale industrial production, and achieve high specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

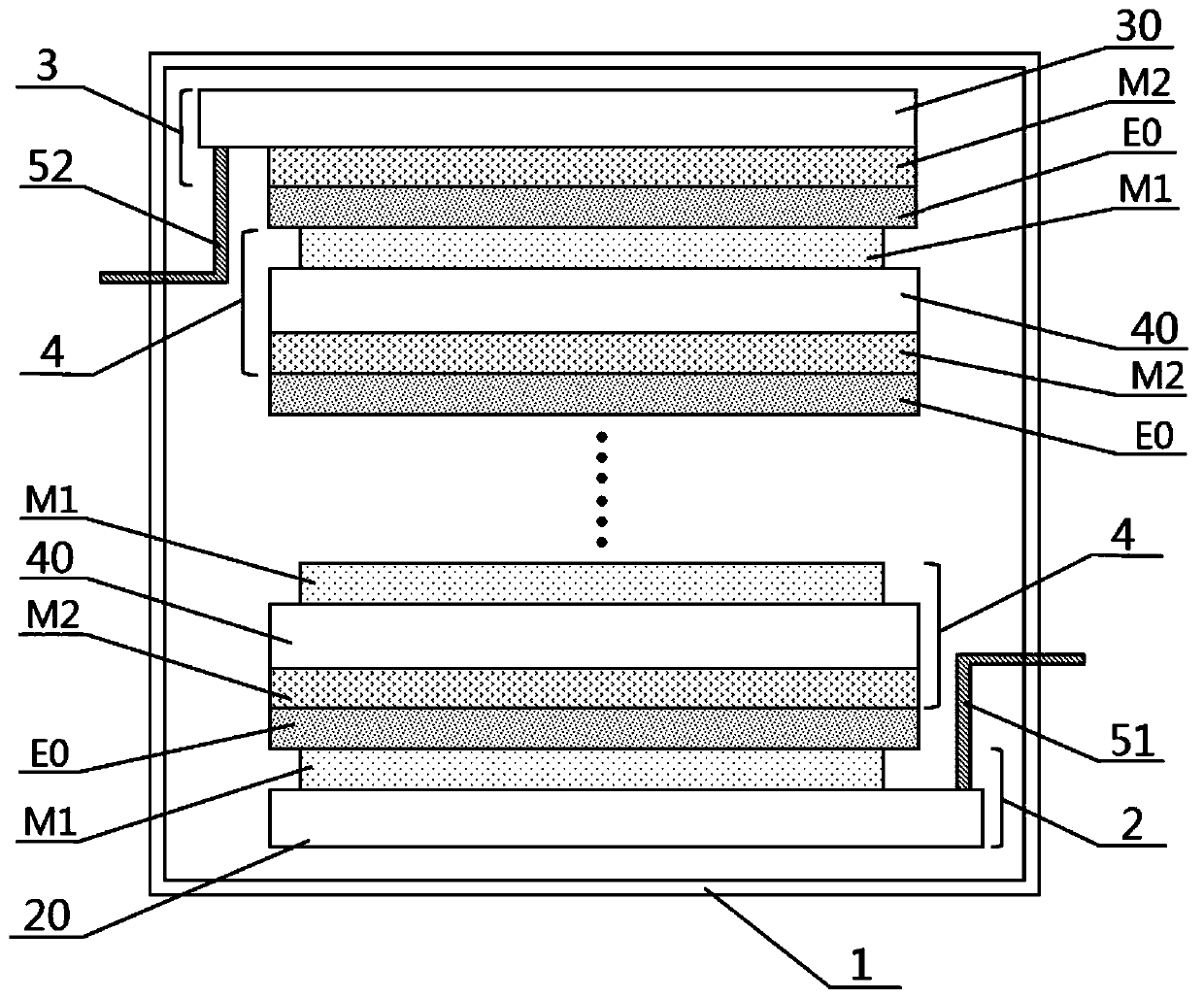

[0045] The embodiment of the present invention also provides the preparation method of the aforementioned high-voltage single lithium-ion solid-state battery, such as Figure 5 shown, including the following steps:

[0046] S1. Prepare metal foil, including the bipolar plate metal foil as the bipolar plate current collector base material, the positive end metal foil as the positive end plate base material, and the negative end metal foil as the negative end plate base material;

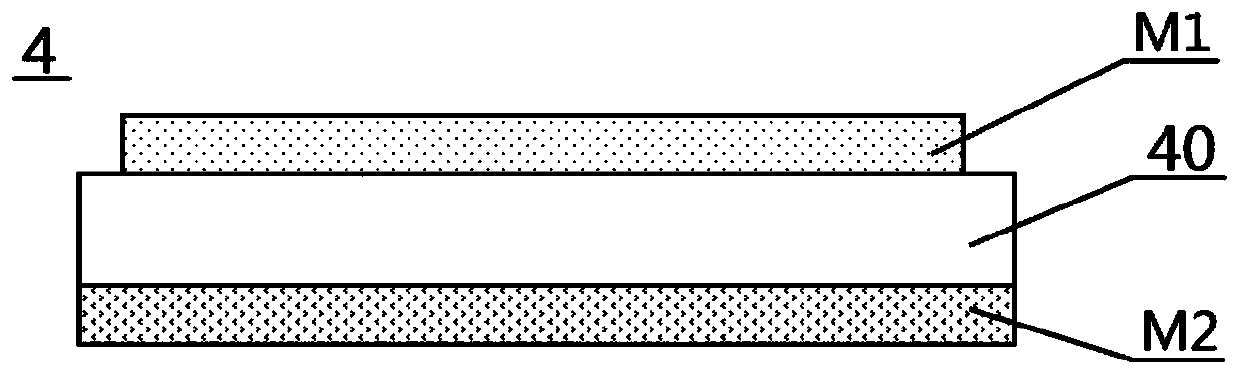

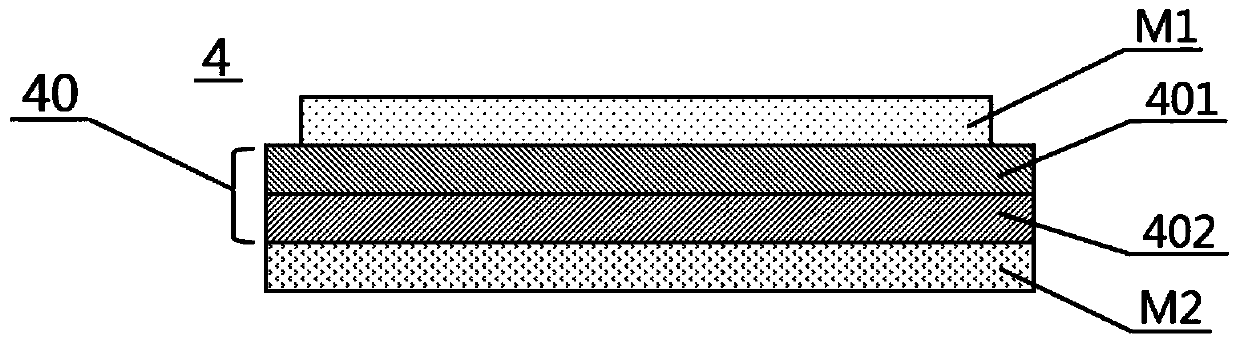

[0047] S2. Coating the positive active material slurry on one side of the metal foil at the positive end, coating the negative active material slurry on one side of the metal foil at the negative end, and coating the positive active material slurry on the positive side and the negative side of the metal foil of the bipolar plate respectively material and negative electrode active material slurry, so that the area of the negative electrode active material layer formed by coating is greater than the a...

Embodiment 1

[0061] The bipolar plate current collector, the positive end plate and the negative end plate are all made of copper-aluminum composite metal foil with a thickness of 30 μm. Both the positive end plate and the negative end plate are coated with active materials on both sides. The positive active material layer and the negative active material layer The surface is coated with a solid electrolyte layer; the aluminum foil side is the positive electrode side, the coated positive electrode active material is lithium iron phosphate, the copper foil side is the negative electrode side, the coated negative electrode active material is graphite, and the solid electrolyte layer is LiPON (lithium phosphorus oxynitride). The specific process is as follows:

[0062] On both sides of the copper-aluminum composite metal foil with a width of 150mm, the positive lithium iron phosphate and the negative graphite are respectively coated. The coating process is the same as the extrusion coating pr...

Embodiment 2

[0065] The bipolar plate current collector, the positive end plate and the negative end plate are all made of aluminum foil with a thickness of 30 μm. Both the positive end plate and the negative end plate are coated with active materials on both sides, and only the surface of the positive active material layer is coated with a solid electrolyte layer. ; The coated positive active material is lithium iron phosphate, the coated negative active material is lithium titanate, and the solid electrolyte layer is Li 2 S-P 2 S 5 . The specific process is as follows:

[0066] The positive electrode lithium iron phosphate and the negative electrode lithium titanate are respectively coated on both sides of the aluminum foil with a width of 150mm; the coating width of the positive electrode active material lithium iron phosphate slurry on the positive side of the aluminum foil is 143mm, and the aluminum foil is uniformly left blank at 3.5mm each. mm, at the same time, the longitudinal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com