Harmless treatment and utilization method for aluminum ash

A technology for harmless treatment of aluminum ash, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of targeted treatment of environmental hazards, insufficient attention to environmental hazards and their treatment, etc. Slight effect of environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

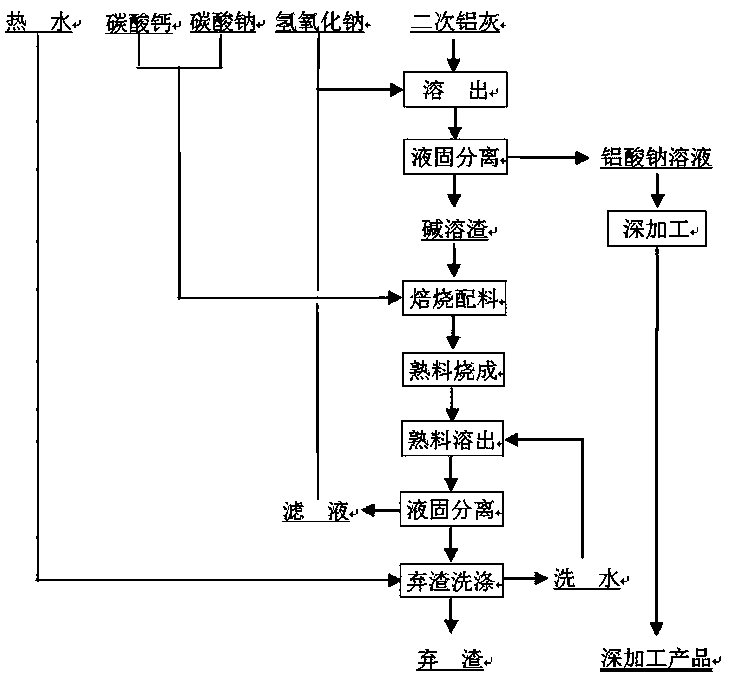

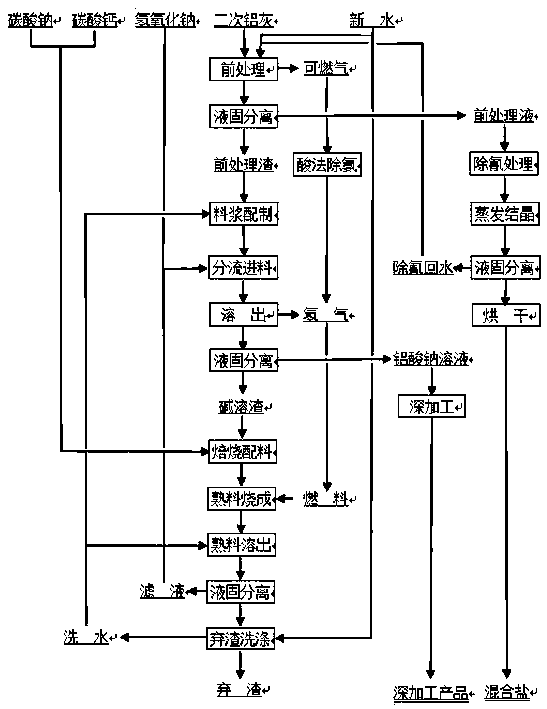

Image

Examples

Embodiment 1

[0031]The secondary aluminum ash raw material is obtained from the primary aluminum ash produced in the primary aluminum production process through aluminum extraction, and no chloride additive is added during the aluminum extraction process. The main element content is: Al: 50% (including 15% of Al elemental substance); Si: 1%; Fe: 1%; K: 0.5%; Na: 5%; Ca: 1%; Mg: 0.5%; Cl : 0.5%; F: 8%; O: 30%; N: 2%; the rest are other elements. The above elements are mainly derived from the oxides and nitrides formed by the reaction of high-temperature liquid aluminum and air during the production of primary aluminum, as well as trace carbides and cyanides produced by the reaction of carbon anodes; cryolite (Na 3 AlF 6 ) mainly fluoride; a small amount of chloride introduced in the refining process before casting and other oxide impurities introduced in the production process and aluminum element entrained in the process of removing the above-mentioned slag phase.

[0032] Firstly, pre-t...

Embodiment 2

[0038] The secondary aluminum ash raw material is obtained from the primary aluminum ash produced in the primary aluminum production process through aluminum extraction, and the aluminum extraction process uses chloride additives. The content of the main elements is: Al: 40% (of which 5% of Al elemental substance); Si: 1%; Fe: 1%; K: 5%; Na: 7%; Ca: 1%; Mg: 2%; Cl: 8%; F: 4%; O: 28%; N: 2%; the rest are other elements. The above elements mainly come from the oxides and nitrides formed by the reaction between high-temperature liquid aluminum and air during the primary aluminum production process; trace carbides and cyanides produced by the reaction with carbon anodes; cryolite (Na 3 AlF 6 )-based fluoride; other oxide impurities introduced during the production process and the aluminum element entrained in the process of removing the above-mentioned slag phase; chlorides introduced during the primary aluminum ash extraction process.

[0039] Firstly, pre-treat the above-menti...

Embodiment 3

[0045] The secondary aluminum ash raw material is obtained from the primary aluminum ash produced in the production process of secondary aluminum through aluminum extraction, and no chloride additive is used in the aluminum extraction process. The content of the main elements is: Al: 43% (of which Al is 10%); Si: 8%; Fe: 1%; K: 1%; Na: 2%; Ca: 1.5%; Mg: 8%; Cl: 2%; F: 0.5%; O: 30%; N: 2%; the rest are other elements. The above elements mainly come from the oxides, nitrides and trace carbides and cyanides formed by the reaction between high-temperature liquid aluminum and air during the production of recycled aluminum; chlorides and fluorides introduced by covering agents and refining agents in the smelting process; Burning loss of alloying elements (mainly magnesium, silicon) and oxide impurities introduced in the production process; aluminum element entrained in the process of removing the above slag phase.

[0046] First, pre-treat the aluminum ash raw material: add water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com