Clean method for extracting vanadium during roasting vanadium slag

A technology of roasting and vanadium slag, applied in the field of vanadium chemical metallurgy, can solve the problems of high price, high cost, unsuitable for large-scale industrial application, etc., and achieve the effect of improving recovery rate, high conversion rate, good economic benefits and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

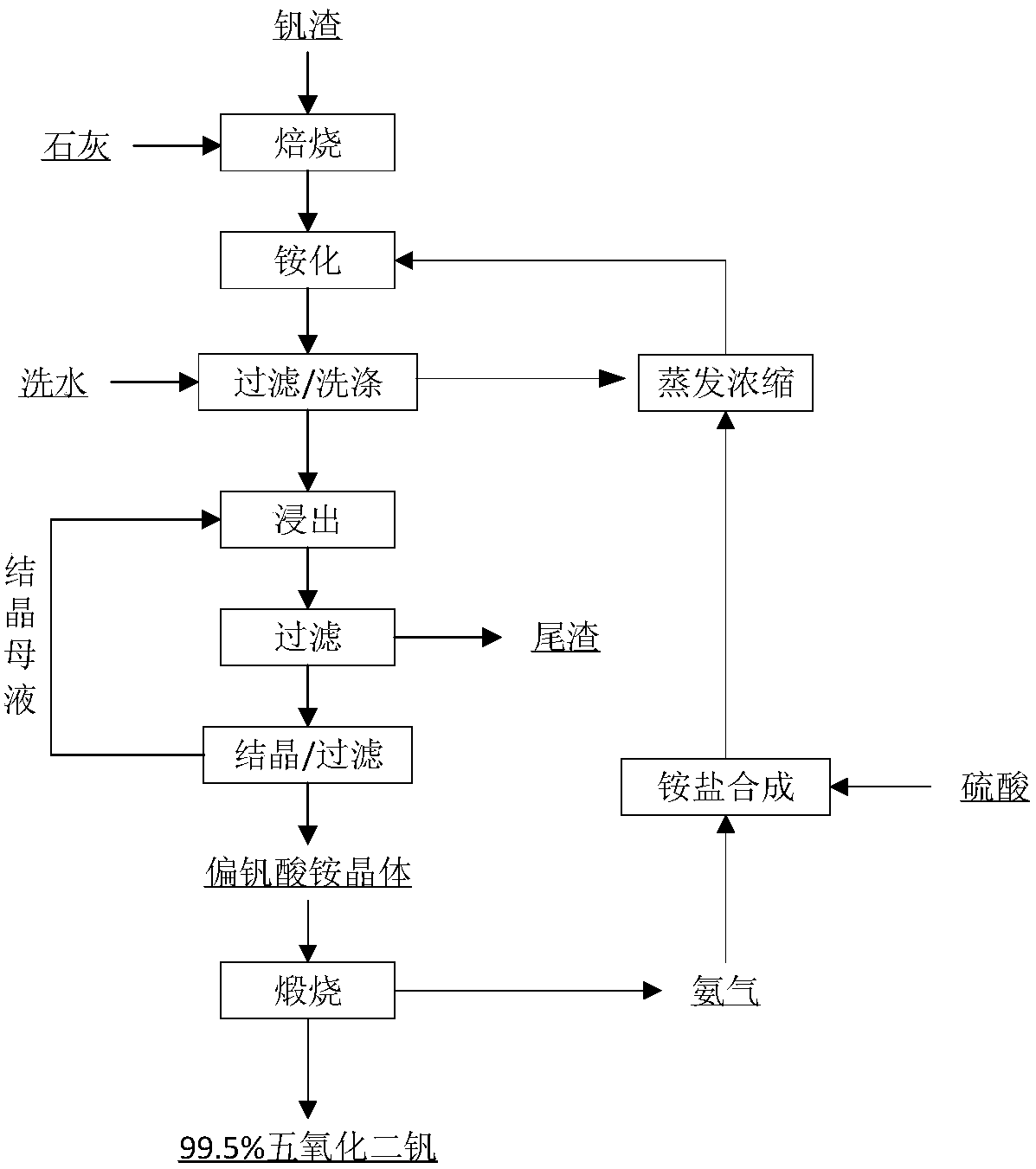

[0056] Such as figure 1 Shown, the present invention carries out extracting vanadium according to the following method:

[0057] (1) Lime and vanadium slag according to CaO:V 2 o 5 =The molar ratio of 1:1 is mixed evenly, and high-temperature roasting is carried out in a rotary kiln, the roasting temperature is 900°C, and the roasting time is 1h;

[0058] (2) Add the calcined clinker to the ammonium sulfate solution for ammonization, and the NH in the solution 4 + The concentration is 50g / L, the ammonization temperature is 80°C, the liquid-solid mass ratio is 3:1, and the ammonization time is 0.1h. After the reaction is completed, filter to obtain the ammonium metavanadate concentration of 2g / L after ammonium liquid and Contains crystal slag;

[0059] (3) Perform three-stage countercurrent washing on the crystal-containing slag with washing water 0.5 times its dry basis weight, mix the lotion with the ammonized liquid, add the washed crystal-containing slag to hot liquid ...

Embodiment 2

[0063] (1) Lime and vanadium slag according to CaO:V 2 o 5 = 1.2:1 molar ratio mixed evenly, high-temperature roasting in a rotary kiln, the roasting temperature is 800 ℃, and the roasting time is 0.8h;

[0064] (2) Add the calcined clinker to the ammonium sulfate solution for ammonization, and the NH in the solution 4 + The concentration is 40g / L, the ammonization temperature is 82°C, the liquid-solid mass ratio is 3.5:1, and the ammonization time is 0.2h. After the reaction is completed, filter to obtain the ammonium metavanadate concentration of 1.6g / L. and crystalline slag;

[0065] (3) Use 0.55 times the dry weight of the washing water to perform three-stage countercurrent washing on the crystal-containing slag, mix the lotion with the ammonized liquid, add the washed crystal-containing slag to hot liquid for leaching, and the leaching temperature is 85°C , the leaching time is 2.4h, after the leaching is completed, filter to obtain a vanadium-containing solution, and...

Embodiment 3

[0069] (1) Lime and vanadium slag according to CaO:V 2 o 5 =1.7:1 molar ratio mixed evenly, high-temperature roasting in the rotary kiln, the roasting temperature is 850 ℃, and the roasting time is 0.5h;

[0070] (2) Add the calcined clinker to the ammonium sulfate solution for ammonization, and the NH in the solution 4 + The concentration is 50g / L, the ammonization temperature is 85°C, the liquid-solid mass ratio is 4.6:1, and the ammonization time is 0.3h. After the reaction is completed, filter to obtain the ammonium metavanadate concentration of 1g / L. Contains crystal slag;

[0071] (3) Perform three-stage countercurrent washing on the crystal-containing slag with washing water 0.5 times its dry basis weight, mix the washing liquid with the ammonized liquid, add the washed crystal-containing slag to hot liquid for leaching, and the leaching temperature is 90°C , the leaching time is 2.2h, after the leaching is completed, filter to obtain a vanadium-containing solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com