Method for preparing magnesium hydroxide, magnesium oxide and gypsum from dolomite lime denitration and desulfurization of flue gas

A technology of magnesium hydroxide and magnesium oxide, applied in magnesium hydroxide, chemical instruments and methods, magnesium oxide and other directions, can solve problems such as separation of calcium and magnesium from dolomitic lime, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

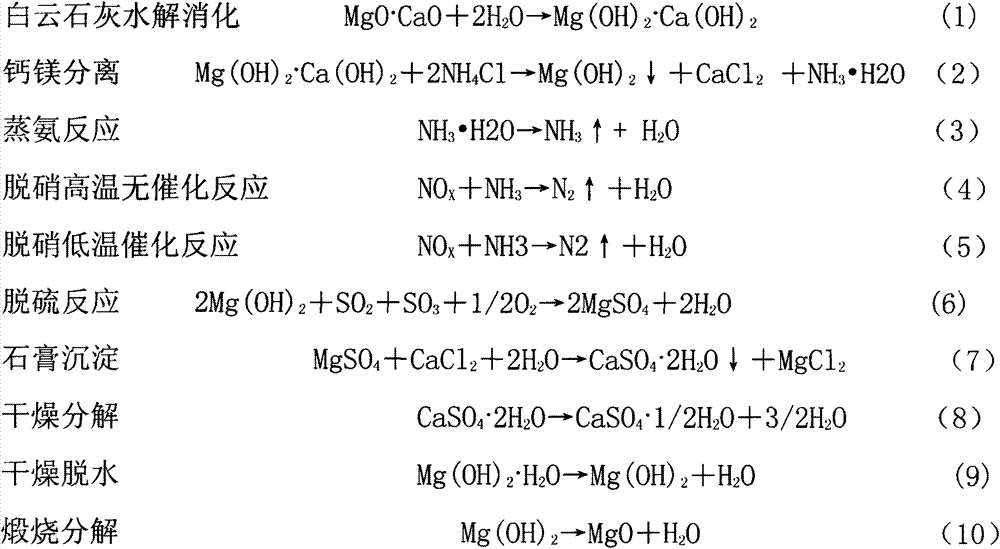

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: The present invention denitrates and desulfurizes and produces magnesium hydroxide, magnesium oxide, the method for building gypsum comprising the following steps:

[0059] ① Digestion and refining step: Digest dolomite lime containing 5% sand and dolomite raw blocks and water into a digestion reactor in a weight ratio of 1:6 while stirring to make dolomite milk, so that MgO CaO (dolomite lime) Form Mg(OH) with water 2 ·Ca(OH) 2 water mixture. Remove impurities such as sand grains and dolomite raw blocks in the ashes by filtering and sieving to obtain refined ashes with a concentration of 10-20%;

[0060] ②Calcium-magnesium separation ammonia distillation step: inject refined dolomite lime milk into the calcium-magnesium separation ammonia distillation reactor, add a sufficient amount of 10% NH 4 Cl solution, close the feeding port, start the agitator, feed steam to directly heat for calcium and magnesium separation reaction, start the fan at the air di...

Embodiment 2

[0066] Embodiment 2: the present invention denitrates and desulfurizes and produces magnesium hydroxide, magnesium oxide, the method for building gypsum comprising the following steps:

[0067] ① Digestion and refining step: Digest dolomite lime containing 10% impurities such as sand and dolomite raw blocks and water in a digestion reactor in a weight ratio of 1:8 while stirring and digesting into dolomite milk to make MgO CaO (dolomite lime) Form Mg(OH) with water 2 ·Ca(OH) 2 water mixture. Remove impurities such as sand grains and dolomite raw blocks in the ashes by filtering and sieving to obtain refined ashes with a concentration of 10-20%;

[0068] ②Calcium-magnesium separation ammonia distillation step: inject refined dolomite lime milk into the calcium-magnesium separation ammonia distillation reactor, add a sufficient amount of 8% NH 4 Cl solution, close the feeding port, start the agitator, pass in steam to indirect heating for calcium and magnesium separation reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com