Method for carrying out deepwater laying on large-volume reinforced mud-filling tubular bags by using geotextiles-laying vessels

A technology for filling pipe bags with mud and laying out ships, which is applied in construction, infrastructure engineering and other directions, can solve the problems of high personnel safety risks, low construction efficiency, low construction efficiency, etc., and achieves improvement of bag volume and strength, construction quality control , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Utilize the laying ship to lay large-volume reinforced mud-filled pipe bags in deep water, the specific steps are:

[0020] 1. Topographic survey:

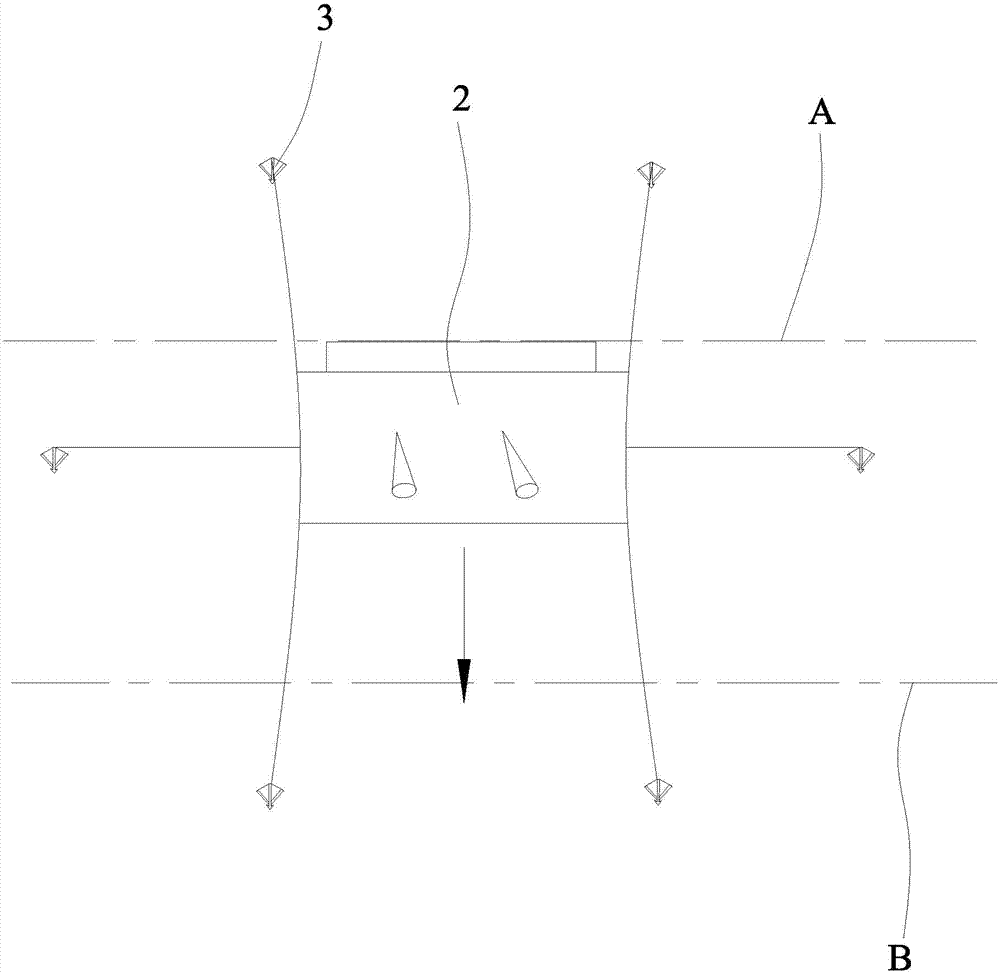

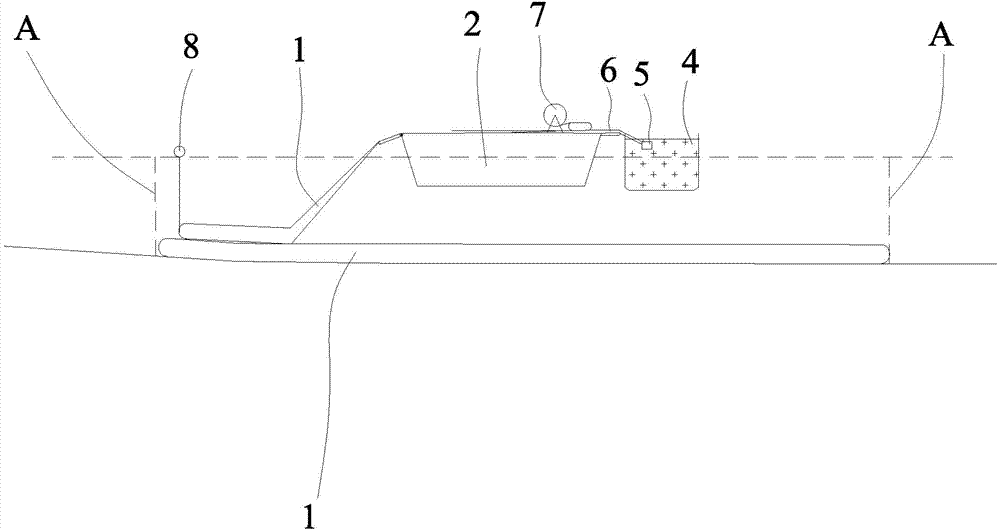

[0021] Use GPS positioning system and shipboard computer monitoring system to measure underwater topography, use the measured data to draw cross-sectional diagrams, use buoys to mark dike axis B and construction sideline A in the construction area according to the measurement results, and measure the bottom of the original deep seabed The elevation is -10 m (Wusong elevation), the width of the deep groove along the direction of water flow is 25 m, and the length of the vertical direction of water flow is 120 m. A laying ship 2 with a drum 7 and a length of 30 m is selected.

[0022] 2. Processing of mud-filled tube bag 1:

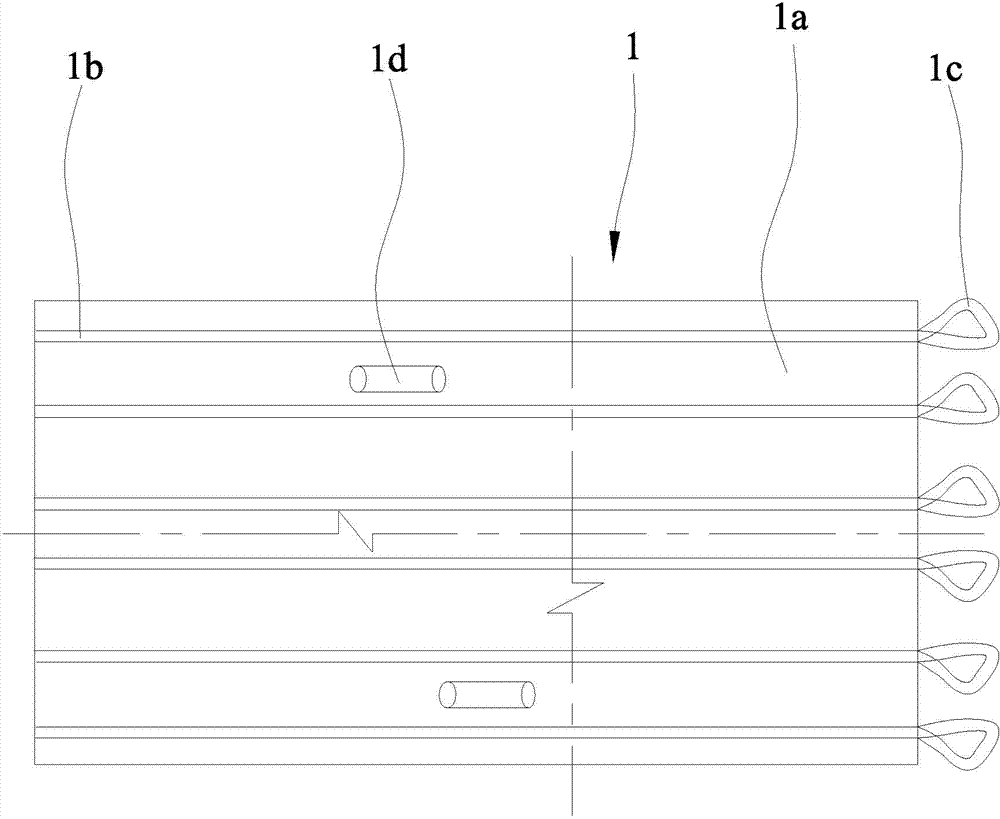

[0023] 1 bag of mud-filled pipe bag is selected as 150 g / m 2 Woven cloth, the bag body 1a is 123 m long and 28 m wide. A certain margin is reserved for the length of the bag body 1a. The ...

Embodiment 2

[0037] Embodiment 2: Utilize the laying ship to lay large-volume reinforced mud-filled pipe bags in deep water. The specific steps are:

[0038] 1. Topographic survey:

[0039] Utilize GPS positioning system and shipboard computer monitoring system to conduct underwater topographic survey, use the measured data to draw cross-sectional diagrams, use buoys to mark dike axis B and construction sideline A in the construction area according to the survey results, and measure the elevation of the original beach in the enclosed area It is -3.5~-5.0 m (National 85 elevation), the width of the deep groove along the flow direction is 36 m, the length in the vertical flow direction is 156 m, the bottom elevation is -11 m, and the laying ship 2 with the drum 7 and the length of 40 m is selected.

[0040] 2. Processing of mud-filled tube bag 1:

[0041] 230 g / m is used for 1 bag of mud-filled pipe bag 2 Polypropylene filament woven fabric, the bag body 1a is 162 m long and 38.4 m wide. A c...

Embodiment 3

[0055] Embodiment 3: Utilize the laying ship to lay large-volume reinforced mud-filled pipe bags in deep water. The specific steps are:

[0056] 1. Topographic survey:

[0057] Use GPS positioning system and shipboard computer monitoring system to measure underwater topography, use the measured data to draw cross-sectional diagrams, use buoys to mark dike axis B and construction sideline A in the construction area according to the measurement results, and the measured bottom elevation of the beach is -5 ~-6.5 m (Wusong Elevation), embankment height below -1 m (Wusong Elevation) uses mud-filled pipe bags for underwater construction, the bottom width of the embankment is 76 m, the slope ratio is 1:3, and the engineering volume is 362,200 m 3 , choose the laying ship 2 with the drum 7 length of 45 m.

[0058] 2. Processing of mud-filled tube bag 1:

[0059] 1 bag of mud-filled pipe bag is selected as 150 g / m 2 Woven cloth, the bag body 1a is 79 m long and 42 m wide, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com