New formula and process method for preparing electrolytic manganese slag brick

An electrolytic manganese slag brick, electrolytic manganese slag technology, applied in sustainable waste treatment, solid waste management, climate sustainability and other directions, can solve the problems of electrolytic manganese slag pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

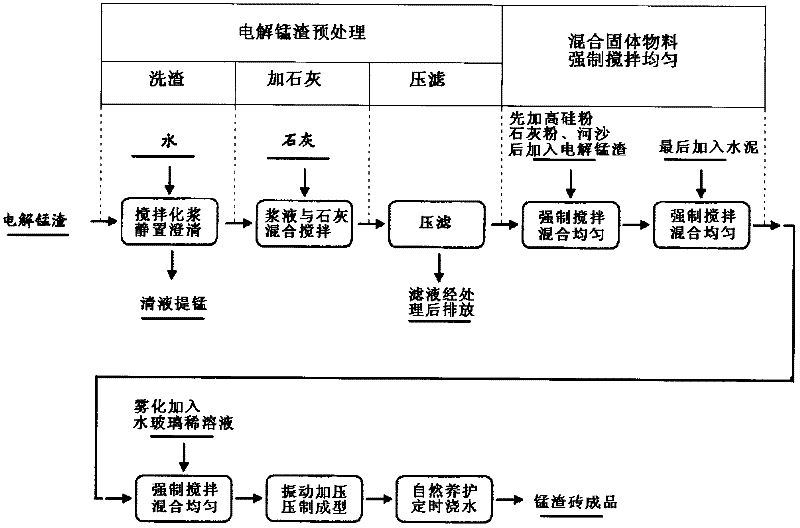

[0021] The specific implementation of the present invention needs to deal with the electrolytic manganese slag first: the electrolytic manganese slag is washed with the "small amount of multiple times" slag washing principle and operation process described in the patented technology "200810044775.3 A kind of process for comprehensive utilization of electrolytic manganese slag", Wash out more than 80% of manganese sulfate and ammonium sulfate and other water-soluble sulfates in the slag, and reuse the slag washing liquid to produce electrolytic metal manganese or manganese compounds. After several consecutive slag washings, when the last washing After the slag liquid flows out, add lime slurry after quickliming water to the remaining slag slurry, adjust the pH value to 8-10, stir for 0.5 hours, and send the electrolytic manganese slag slurry after adding lime into the plate and frame filter press Press filtration is carried out, and the filtrate is discharged after being treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com