Technology for comprehensively recycling leaching residue in production of electrolytic manganese metal and manganese dioxide

A technology of electrolytic manganese metal and manganese dioxide, applied in the direction of process efficiency improvement, application, ammonium sulfate, etc., can solve the problems of loss of mineral resources, land consumption, ecological environment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

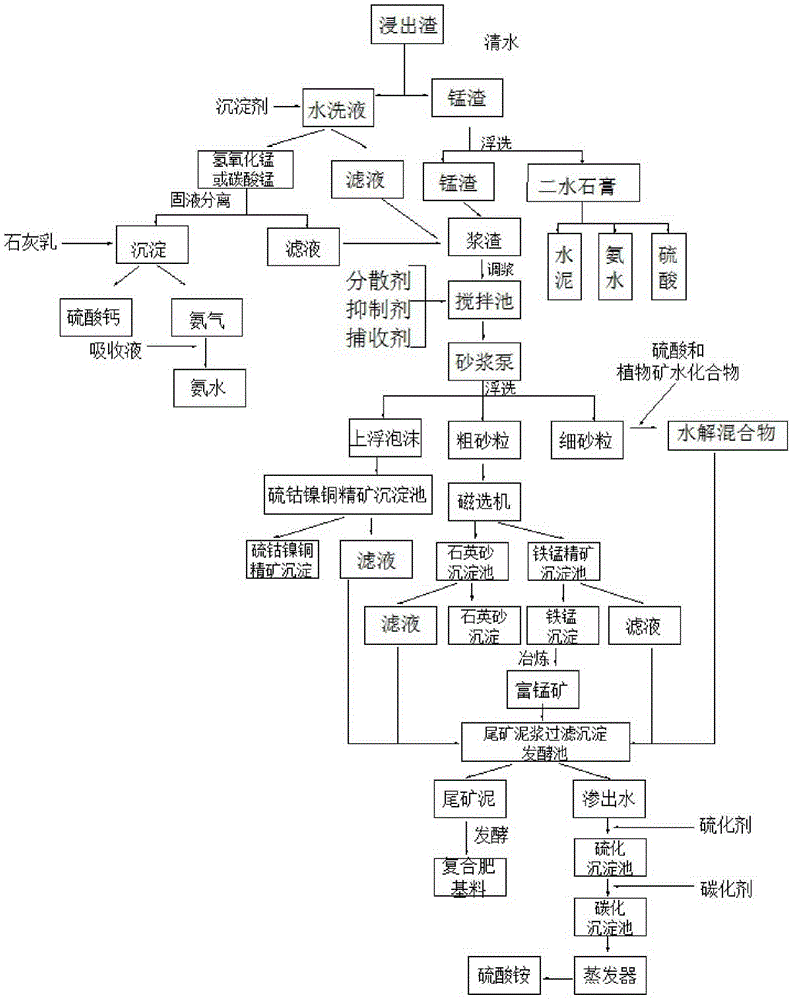

Image

Examples

Embodiment 1

[0038] A process for comprehensive recovery and utilization of leaching slag in the production of electrolytic manganese metal and manganese dioxide, comprising the following steps:

[0039] (1) Mix the leaching slag and clean water according to the mass ratio of 1:10, carry out countercurrent washing in a countercurrent drum washing machine, and press filter after standing for 20 minutes to obtain a water washing solution containing manganese sulfate and ammonium sulfate. manganese slag;

[0040] (2) adding ammonia water to the obtained water washing solution, adding the mass concentration of 2% ammonia water according to the mass ratio of the water washing solution and the ammonia water mass ratio of 1:50, the reaction temperature is 30 ℃, and the reaction is carried out for 0.5 hour, and then solid-liquid separation is carried out, Slams are separated;

[0041] (3) Lime milk is added to the liquid after solid-liquid separation for reaction, and the pressure is 30Pa, the re...

Embodiment 2

[0055] A process for comprehensive recovery and utilization of leaching slag in the production of electrolytic manganese metal and manganese dioxide, comprising the following steps:

[0056] (1) The leaching residue and clean water are mixed according to the mass ratio of 3:10 and then washed in countercurrent in the three-dimensional single-stage thickener. After standing for 25 minutes, press filtration to obtain the water washing solution containing manganese sulfate and ammonium sulfate and the water washing solution. manganese slag;

[0057] (2) adding ammonia water to the obtained water washing solution, adding the mass concentration of 7:50 according to the water washing solution and the ammonia water mass ratio and adding the mass concentration is 2% ammonia water, the reaction temperature is 50 ℃, and the reaction is carried out for 0.8 hours, and then solid-liquid separation is carried out, Slams are separated;

Embodiment 3

[0072] A process for comprehensive recovery and utilization of leaching slag in the production of electrolytic manganese metal and manganese dioxide, comprising the following steps:

[0073] (1) After mixing the leaching residue and clean water as 5:10 by mass ratio, carry out countercurrent washing in a three-dimensional multi-stage thickener, and press filtration after standing for 35 minutes to obtain a water washing solution containing manganese sulfate and ammonium sulfate and a water washing solution. manganese slag;

[0074] (2) adding ammonium bicarbonate to the water washing solution obtained, adding the addition of a mass concentration of 10:50 according to the water washing solution and ammonium bicarbonate mass ratio is 8% ammonium bicarbonate, temperature of reaction is 100 ℃, and reacts for 1 hour, Then the solid-liquid separation is carried out, and the punch is separated;

[0075] (3) Lime milk is added to the liquid after solid-liquid separation for reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com