A method for recovering lithium from calcium and magnesium slag and preparing ternary precursor material

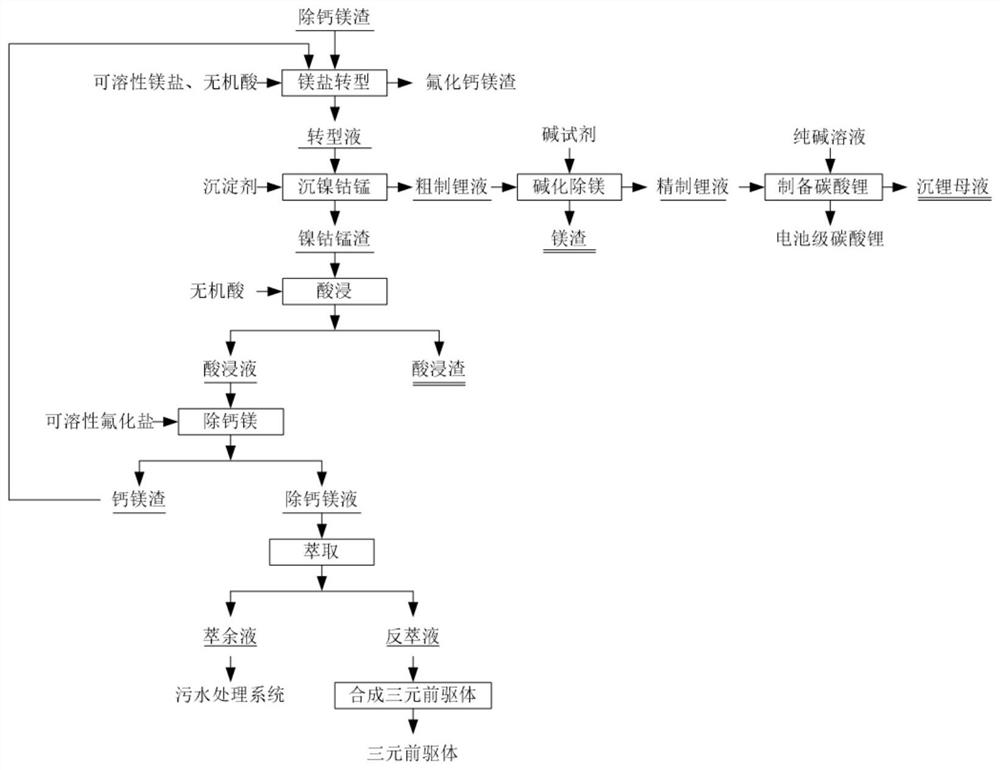

A calcium-magnesium slag and precursor technology is applied in the field of wet recycling of waste lithium batteries, which can solve the problems of reducing the recovery rate of valuable metals, and achieve the effects of high recovery rate, low energy consumption and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (1) Magnesium salt transformation: Take 200kg of calcium-magnesium slag and 0.54m³ magnesium chloride solution with a magnesium ion concentration of 77 g / L to make a slurry. It needs to be 1.1 times the theoretical mass, and then adjust the pH value of the system to 3.0 with 20L hydrochloric acid. Turn on the heating, keep the system temperature at 95°C and stir for 1 hour, then filter at a stirring rate of 200rps to obtain 0.52 m³ transformation liquid. The analysis results of the main components of the transformation fluid are shown in Table 1 as follows:

[0087] Table 1 Analysis results of main components of transformation fluid

[0088] element co Ni mn Li Ca Mg Fe Al Contentg / L 12.80 29.03 15.06 28.5 3.2 13 0.001 0.002

[0089] (2) Immerse nickel, cobalt and manganese: convert the cobalt, nickel and manganese in the 0.52 m³ transformation solution obtained above into nickel hydroxide, cobalt and manganese, and add 45kg o...

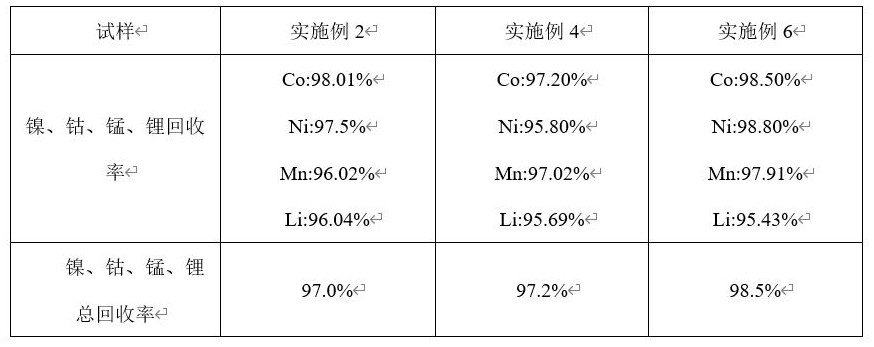

Embodiment 2

[0100] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0101]S1: Alkalinization to remove magnesium: add 0.1 m³ 32wt% sodium hydroxide solution to the 0.46 m³ crude lithium solution obtained in step (2), and adjust the pH value of the solution to 12.0. Stir for 1 h and filter to obtain 0.52 m³ of refined lithium solution. The main component analysis results of the refined lithium solution are shown in Table 3 as follows:

[0102] Table 3 Analysis results of main components of refined lithium solution

[0103] element co Ni mn Li Ca Mg Fe Al Contentg / L 0.0001 not detected 0.0005 28.47 0.12 0.0001 0.0005 0.0002

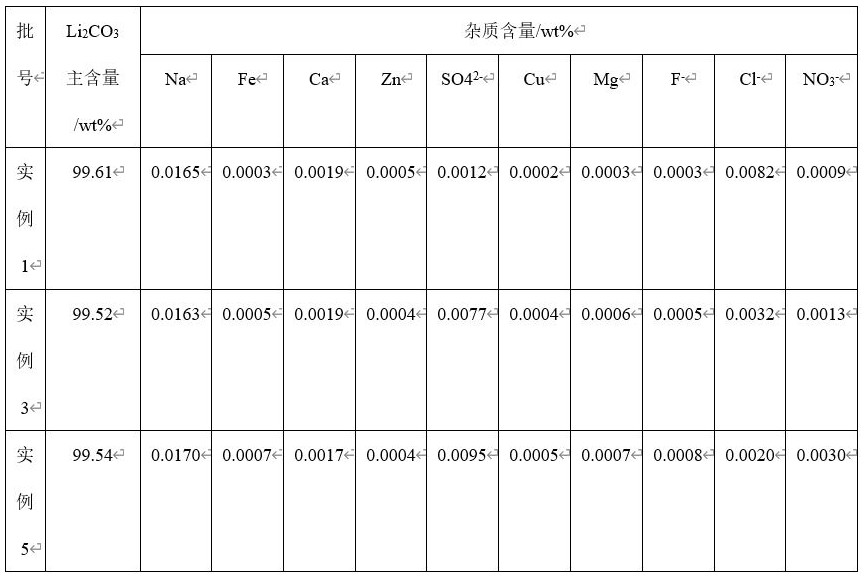

[0104] S2: Preparation of lithium carbonate: heat up the refined lithium solution to 95°C, then slowly add 0.37m³ of 300g / L sodium carbonate solution, stir for 0.5h and filter, with a stirring rate of 250 rps. Filter residue obtains 75.77kg lithium carbonate product through washing, drying ...

Embodiment 3

[0106] (1) Magnesium salt transformation: Take 200kg of calcium-magnesium slag and 0.6m³magnesium ion concentration of 61 g / L magnesium sulfate solution to make a slurry. 1.2 times of the required theoretical amount, and then adjust the pH value of the system to 1.0 with 20L concentrated sulfuric acid. Turn on the heating, keep the system temperature at 95°C and stir for 1 hour, then filter at a stirring rate of 200rps to obtain 0.63 m³ transformation liquid. The main component analysis results of transformation fluid are shown in Table 5 as follows:

[0107] Table 5 Analysis results of main components of transformation fluid

[0108] element co Ni mn Li Ca Mg Fe Al Contentg / L 6.3 14.6 3.2 22.1 1.1 8.5 0.002 0.001

[0109] (2) Precipitated cobalt-nickel-manganese: According to the step (1), the cobalt, nickel, and manganese in the 0.63 m³ transformation solution are all converted into nickel hydroxide, cobalt-manganese, and 1.1 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com