Preparation method of silver/carbon quantum dot composite nanometer materials

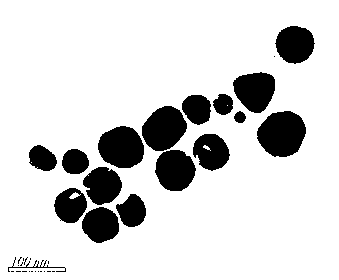

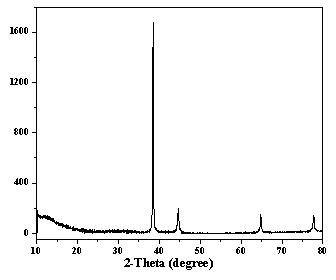

A technology of composite nanomaterials and carbon quantum dots, which is applied in the field of preparation of silver/carbon quantum dots composite nanomaterials, can solve problems such as being unsuitable for large-scale production and difficult to separate products, and achieves good application prospects, good dispersibility, and particle size. Uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve 0.1g PVP in 10mL distilled water, measure 5mL AgNO 3 (0.03mol / L) was added to the above PVP solution, and after stirring at room temperature for 10min, the prepared 10mL carbon quantum dot solution (0.1g / L) was added to the above mixture, and after stirring continuously for 20min, the reaction solution was transferred into 50mL In a hydrothermal kettle, put it in an electronic oven at 140°C, and react for 8 hours; after the reaction is completed, the product obtained is centrifuged, washed with distilled water and ethanol for several times, and dried in a vacuum oven.

Embodiment 2

[0019] Dissolve 0.1g PVP in 10mL distilled water, measure 5mL AgNO 3 (0.02mol / L) was added to the above PVP solution, and after stirring at room temperature for 10 minutes, the prepared 10ml carbon quantum dot solution (0.1g / L) was added to the above mixture, and after continuous stirring for 20 minutes, the reaction solution was transferred into 50mL In a hydrothermal kettle, put it in an electronic oven at 160°C, and react for 4 hours; after the reaction is completed, the product obtained is centrifuged, washed with distilled water and ethanol for several times, and dried in a vacuum oven.

Embodiment 3

[0021] Dissolve 0.1g PVP in 10mL distilled water, measure 5mL AgNO 3 (0.02mol / L) was added to the above PVP solution, and after stirring at room temperature for 10min, the prepared 10mL carbon quantum dot solution (0.1g / L) was added to the above mixture, and after stirring continuously for 20min, the reaction solution was transferred into 50mL In a hydrothermal kettle, put it in an electronic oven at 180°C, and react for 4 hours; after the reaction is completed, the product obtained is centrifuged, washed with distilled water and ethanol for several times, and dried in a vacuum oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com