Polypropylene powder for selective laser sintering and preparation thereof

A technology of laser sintering and polypropylene, applied in the direction of additive processing, etc., can solve the problems of increasing the production cost of emulsification and evaporation solvent method, affecting the performance of polymer powder, difficult to remove stabilizers and emulsifiers, etc., to achieve particle size distribution and Improved fluidity, high sphericity, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

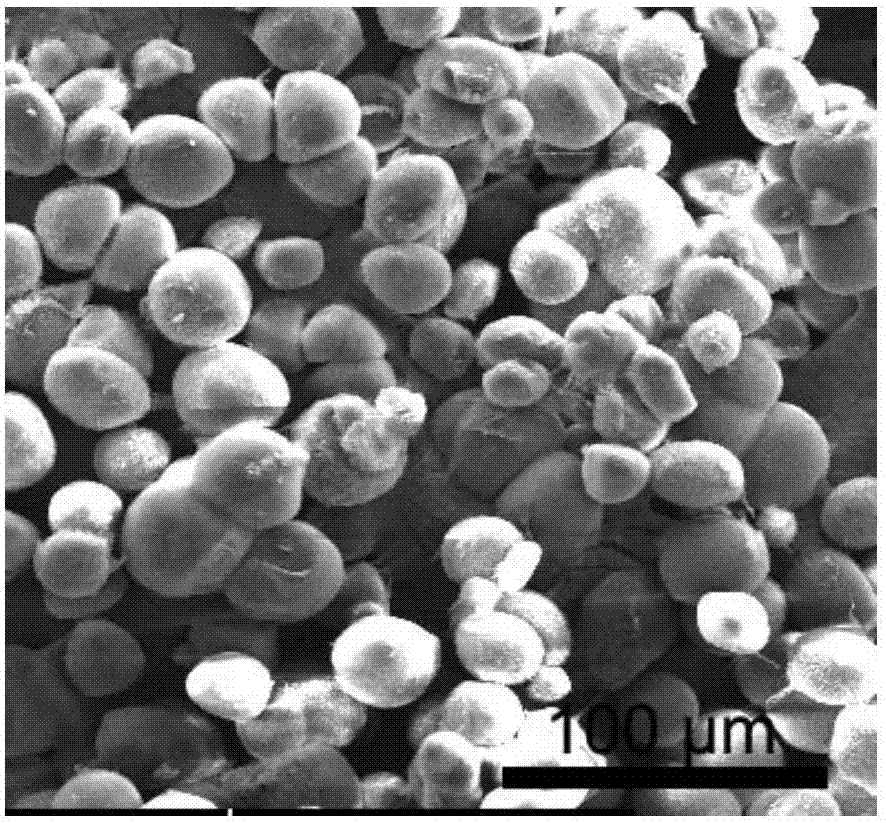

[0051] Add 3 grams of polypropylene material (product brand Y3700C, whose melt index is 40g / 10min as measured by the above method) and 100 milliliters of xylene into a 250 milliliter flask, heat the flask to 145°C, and stir at this temperature For 60 minutes, the stirring speed was 50 rpm to form a homogeneous polypropylene solution. Quickly put the flask containing the polypropylene solution into an ice-water bath at 0°C to quench, and continue to stand at this temperature for 30 minutes. It can be observed that polypropylene particles are precipitated from the solution, filtered, washed, and dried to obtain poly Propylene powder (referred to as PP powder). Sieve the PP powder and collect the PP powder with a particle size in the range of 100-800 mesh. Its appearance is as follows: figure 1 shown. It is determined that the prepared polypropylene powder has a particle size of 16-86 μm, a particle size distribution of D10=17 μm, D50=53 μm, and D90=75 μm. The bulk density of ...

Embodiment 2

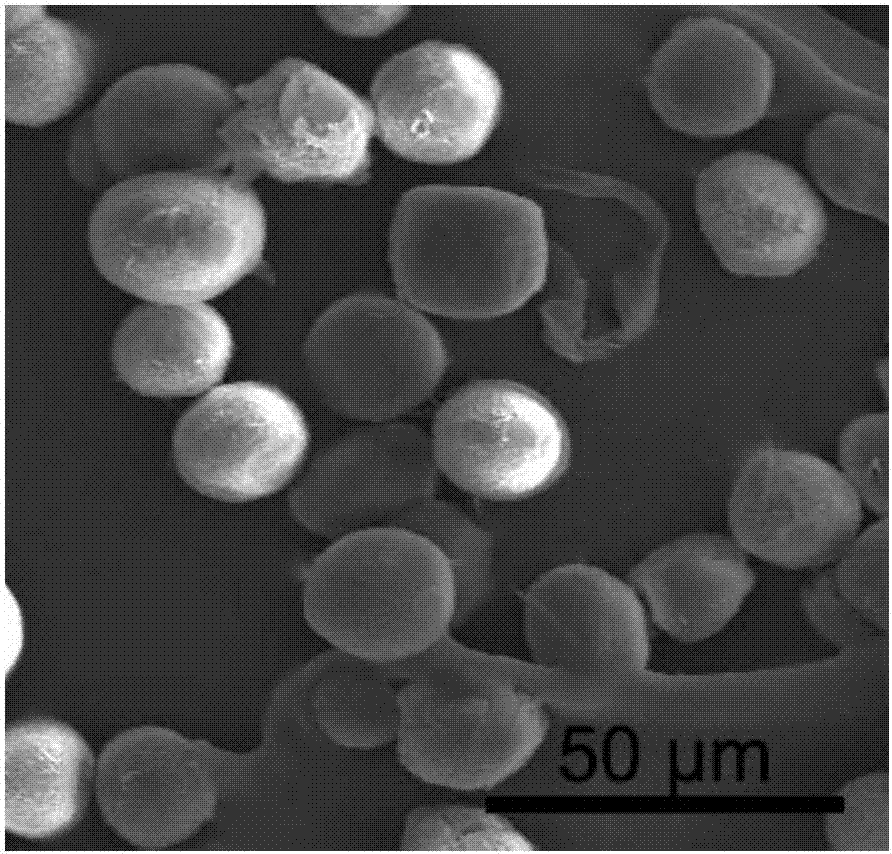

[0053] Add 1 gram of polypropylene material (product brand V30S, melt index: 10g / 10min) and 10 liters of xylene into a 25-liter reactor, heat the flask to 145°C, and stir at this temperature for 60 minutes at a constant temperature. at 30 rpm to form a homogeneous polypropylene solution. Pass an ice-water bath at 0°C into the jacket of the reaction kettle to quench the polypropylene solution, and continue to stand at this temperature for 30 minutes. It can be observed that the polypropylene particles are precipitated from the solution, and are suction filtered, washed and dried. , to obtain PP powder. Sieve the PP powder and collect the PP powder with a particle size in the range of 100-800 mesh. Its appearance is as follows: figure 2 shown. It is determined that the prepared polypropylene powder has a particle size of 10-78 μm, a particle size distribution of D10=15 μm, D50=30 μm, and D90=70 μm. The bulk density of polypropylene powder is 0.60g / cm 3 . The sphericity of ...

Embodiment 3

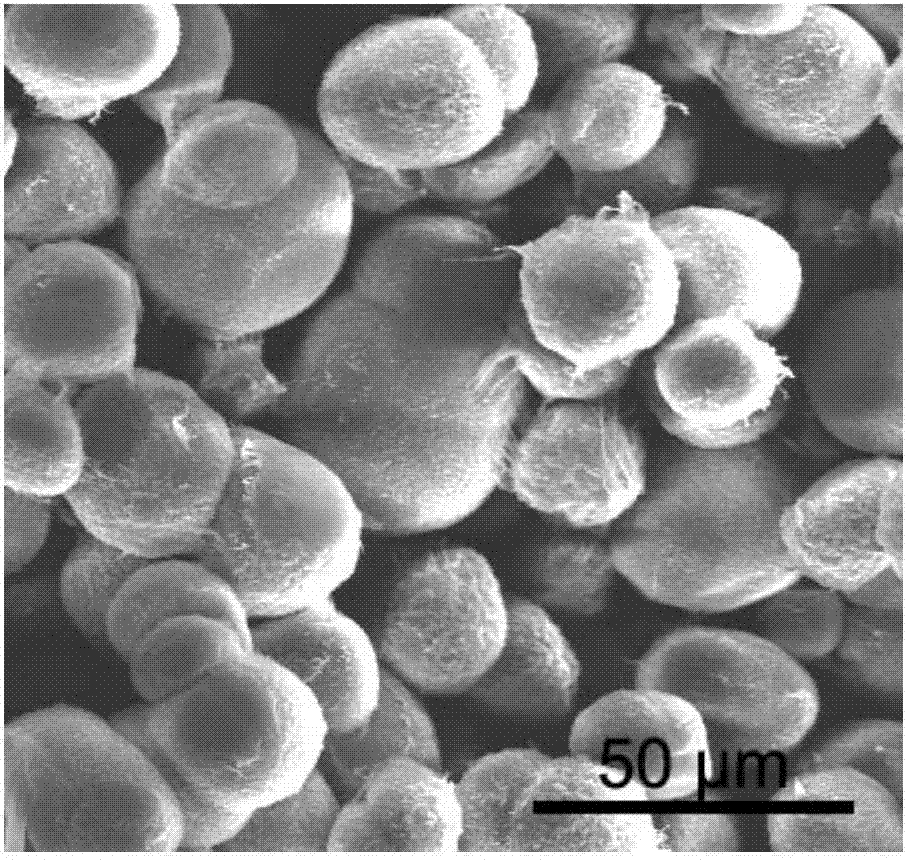

[0055] Add 30 grams of polypropylene material (product brand Y3700C, melt index: 35g / 10min) and 100 milliliters of diphenyl ether into a 250 milliliter flask, heat the flask to 150 ° C, and stir at this temperature for 60 minutes at a constant temperature. at 10 rpm to form a homogeneous polypropylene solution. Quickly put the flask containing the polypropylene solution into liquid nitrogen at -195°C to quench, and continue to stand at this temperature for 60 minutes. It can be observed that the polypropylene particles are precipitated from the solution, and filtered, washed and dried to obtain PP powder. Sieve the PP powder and collect the PP powder with a particle size in the range of 100-800 mesh. Its appearance is as follows: image 3 shown. It is determined that the prepared polypropylene powder has a particle size of 12-83 μm, a particle size distribution of D10=17 μm, D50=39 μm, and D90=72 μm. The bulk density of polypropylene powder is 0.54g / cm 3 . The sphericity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com