Preparation method for denitration catalyst carrier nano titanium dioxide

A nano-titanium dioxide and denitration catalyst technology, which is applied to catalyst carriers, titanium dioxide, chemical instruments and methods, etc., can solve the problems of cumbersome production process, increase production cost, affect single-pass yield, etc., achieve simple process, reduce equipment corrosion, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

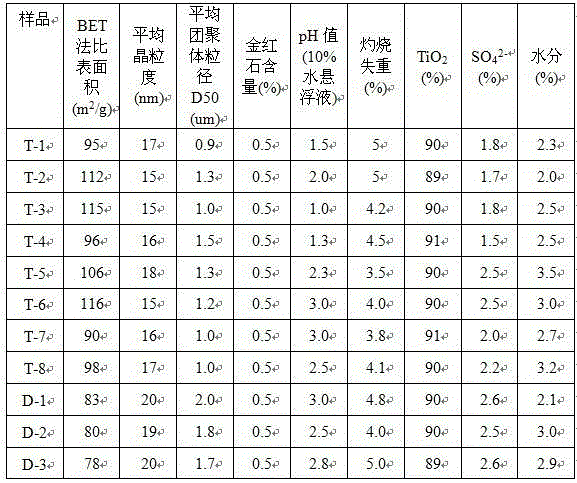

Embodiment 1

[0037] Weigh 15g of metatitanic acid and add 66g of water to beat and disperse under stirring at room temperature, adjust the concentration of the slurry in terms of metatitanic acid to 123g / L, stir at room temperature for 0.5h, and mark it as A.

[0038]Weigh 0.08g of ammonium carbonate and add it to slurry A, stir in a water bath at 50oC for 2 hours, gradually add ammonia water dropwise to adjust the pH value of the slurry to 5, continue to add 0.08g of ammonium polyacrylate and stir for 2 hours; Cool completely, add appropriate amount of deionized water to wash, and finally filter with Buchner funnel, calcinate the filter cake at 100oC for 3h, then calcinate at 200oC for 3h, continue calcining at 300oC for 3h, and finally calcinate at 400oC for 3h, crush and grind to obtain denitrification Catalyst carrier nano titanium dioxide, marked as T-1.

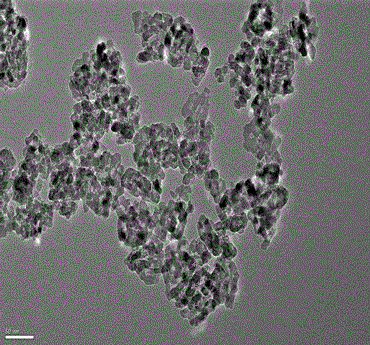

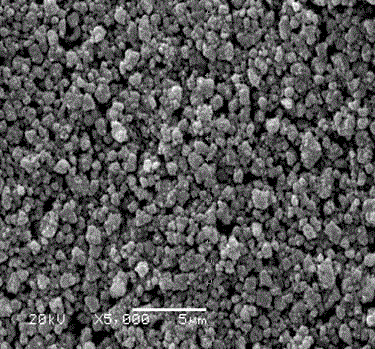

[0039] Depend on figure 1 It can be seen that the titanium dioxide product synthesized by the present invention has uniform parti...

Embodiment 2

[0042] Weigh 20g of metatitanic acid and add 43g of water to beat and disperse under stirring at room temperature, adjust the concentration of the slurry in terms of metatitanic acid to 250g / L, stir at room temperature for 1h, and mark it as B.

[0043] Weigh 0.1g of ammonium carbonate and add it to slurry B, stir in a water bath at 60oC for 1.5h, gradually add ammonia water dropwise to adjust the pH value of the slurry to 5, continue to add 0.10g of ammonium citrate and stir for 2h; Cool completely, add appropriate amount of deionized water to wash, finally filter with Buchner funnel, calcinate the filter cake at 150oC for 3h, then calcinate at 250oC for 3h, continue calcining at 350oC for 3h, and finally calcinate at 450oC for 3h, crush and grind to obtain denitrification Catalyst carrier nano titanium dioxide, marked as T-2.

Embodiment 3

[0045] Weigh 20g of metatitanic acid and add 54g of water to beat and disperse under normal temperature stirring conditions, adjust the concentration of the slurry in terms of metatitanic acid to 200g / L, stir at room temperature for 1h, and mark it as C.

[0046] Weigh 0.07g of ammonium citrate and add it to slurry C, stir in a water bath at 60oC for 0.5h, gradually add ammonia water dropwise to adjust the pH value of the slurry to 7, continue to add 0.03g of ammonium carbonate and stir for 2.5h; Cool the slurry completely, add an appropriate amount of deionized water to wash, and finally filter it with a Buchner funnel, calcinate the filter cake at 150oC for 3h, then calcinate at 250oC for 3h, continue calcining at 350oC for 3h, and finally calcinate at 500oC for 2h, and then grind and grind to obtain The denitrification catalyst supports nano-titanium dioxide, marked as T-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com