Polypropylene compound powder for selective laser sintering and preparation thereof

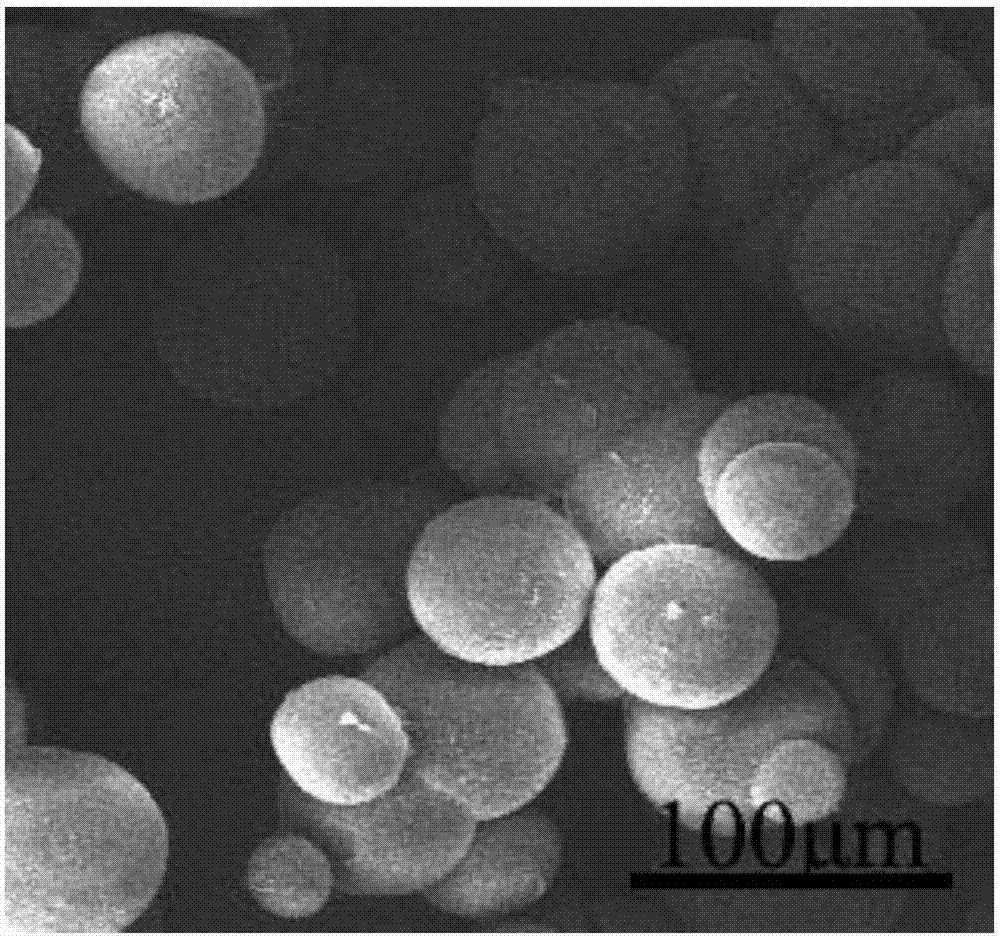

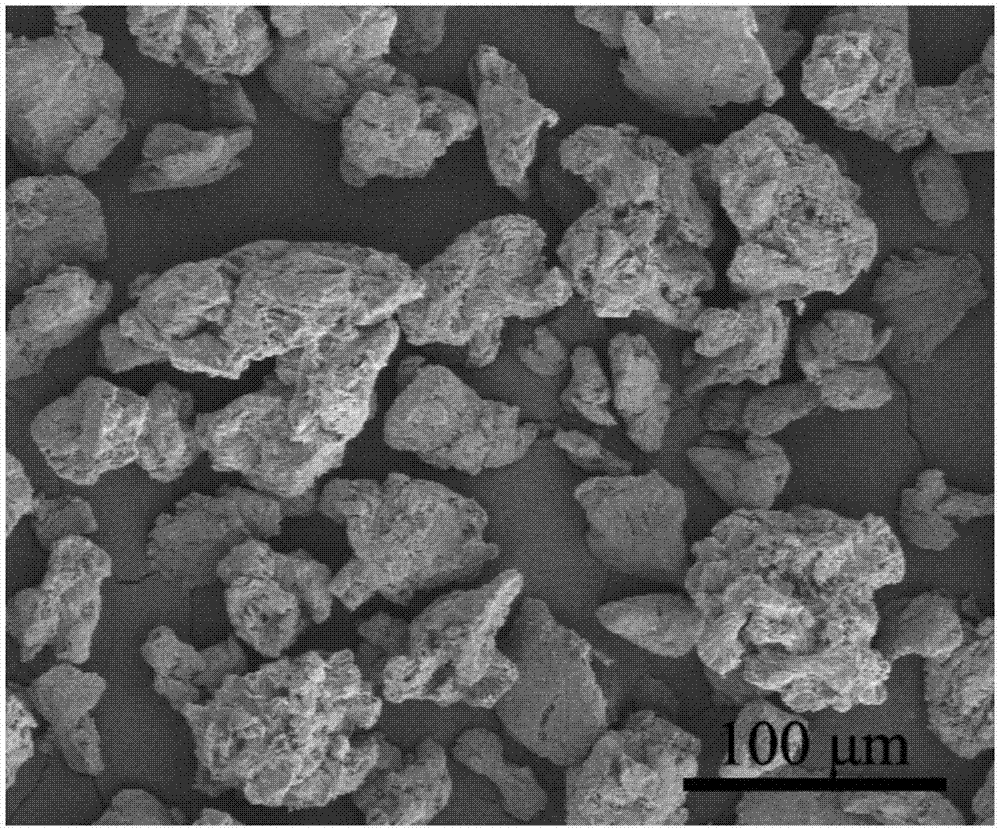

A composite powder, laser sintering technology, applied in the field of polymer processing, can solve the problems of limiting the performance of PP powder application sintered parts, irregular shape of polypropylene powder, difficult to mix PP uniformly, etc., to achieve improved strength and toughness, excellent mechanical properties. , the effect of uniform particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

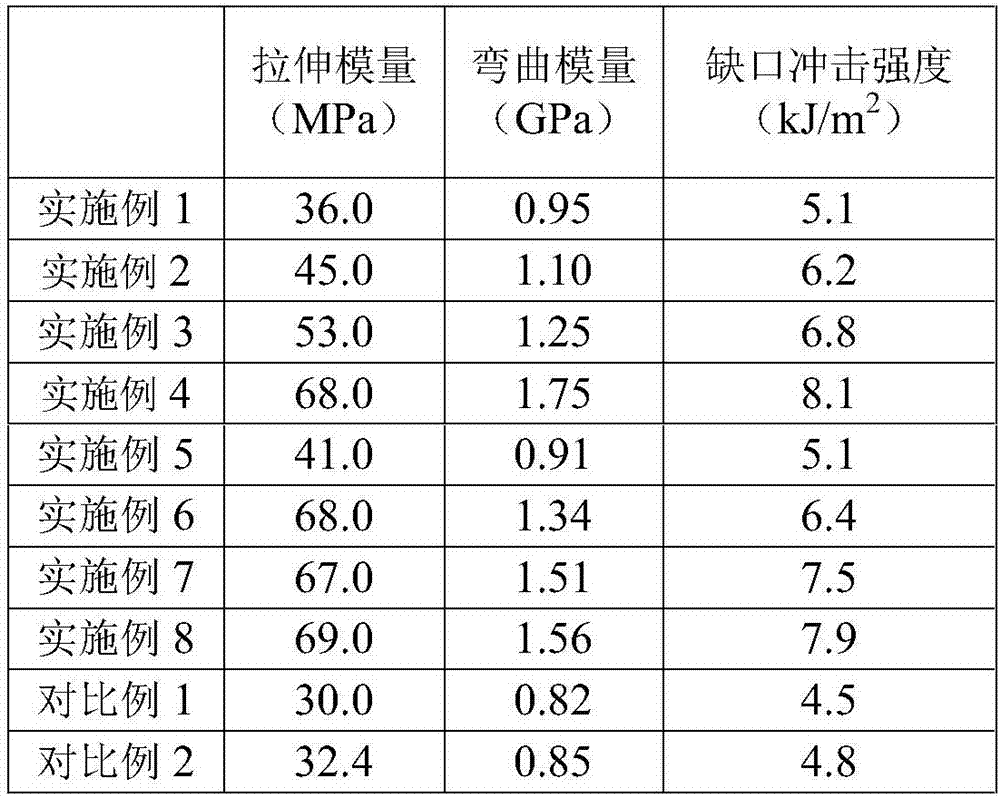

Embodiment 1

[0049] 75g of polypropylene powder (the brand name is T30S, and its melt index is 45g / 10min according to the method described above), maleic anhydride grafted polypropylene (melt index is 60g / 10min, and the grafting rate of maleic anhydride is 0.5%, (manufactured by Nanjing Julong Chemical Co., Ltd.) 25g and 1250mL of xylene were added into the reaction kettle (that is, the concentration of polypropylene in the polypropylene solution was 6.0g / 100mL), heated to 148°C under stirring, and kept stirring at this temperature for 60 minutes , the stirring speed is 50 rpm, the polypropylene powder and the maleic anhydride grafted polypropylene powder are completely dissolved in xylene to form a homogeneous polypropylene solution. Fill the 0°C ice-water mixture into the jacket of the reaction kettle to quench the polypropylene solution in the kettle, and continue to stand at this temperature for 60 minutes, and it can be observed that the polypropylene-maleic anhydride grafted polypropy...

Embodiment 2

[0052] Add 75g of polypropylene powder (brand T30S, melt index 45g / 10min), maleic anhydride grafted polypropylene (melt index 60g / 10min, maleic anhydride graft rate 0.5%) 25g and 1250mL xylene to the reaction In the kettle (that is, the concentration of polypropylene in the polypropylene solution is 6.0g / 100mL), heat it to 148°C under stirring, and stir at this temperature for 60 minutes at a constant temperature at a stirring speed of 50 rpm. Polypropylene powder and Malay The anhydride-grafted polypropylene powder is completely dissolved in xylene to form a homogeneous polypropylene solution. Fill the 0°C ice-water mixture into the jacket of the reaction kettle to quench the polypropylene solution in the kettle, and continue to stand at this temperature for 60 minutes, and it can be observed that the polypropylene-maleic anhydride grafted polypropylene The particles are precipitated from the solution, filtered, washed and dried to obtain polypropylene-maleic anhydride grafte...

Embodiment 3

[0055] Add 75g of polypropylene powder (brand T30S, melt index 45g / 10min), maleic anhydride grafted polypropylene (melt index 60g / 10min, maleic anhydride graft rate 0.5%) 25g and 1250mL xylene to the reaction In the kettle (that is, the concentration of polypropylene in the polypropylene solution is 6.0g / 100mL), heat it to 148°C under stirring, and stir at this temperature for 60 minutes at a constant temperature at a stirring speed of 50 rpm. Polypropylene powder and Malay The anhydride-grafted polypropylene powder is completely dissolved in xylene to form a homogeneous polypropylene solution. Fill the 0°C ice-water mixture into the jacket of the reaction kettle to quench the polypropylene solution in the kettle, and continue to stand at this temperature for 60 minutes, and it can be observed that the polypropylene-maleic anhydride grafted polypropylene The particles are precipitated from the solution, filtered, washed and dried to obtain polypropylene-maleic anhydride grafte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com