Universal powdered ink

A general purpose, toner technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

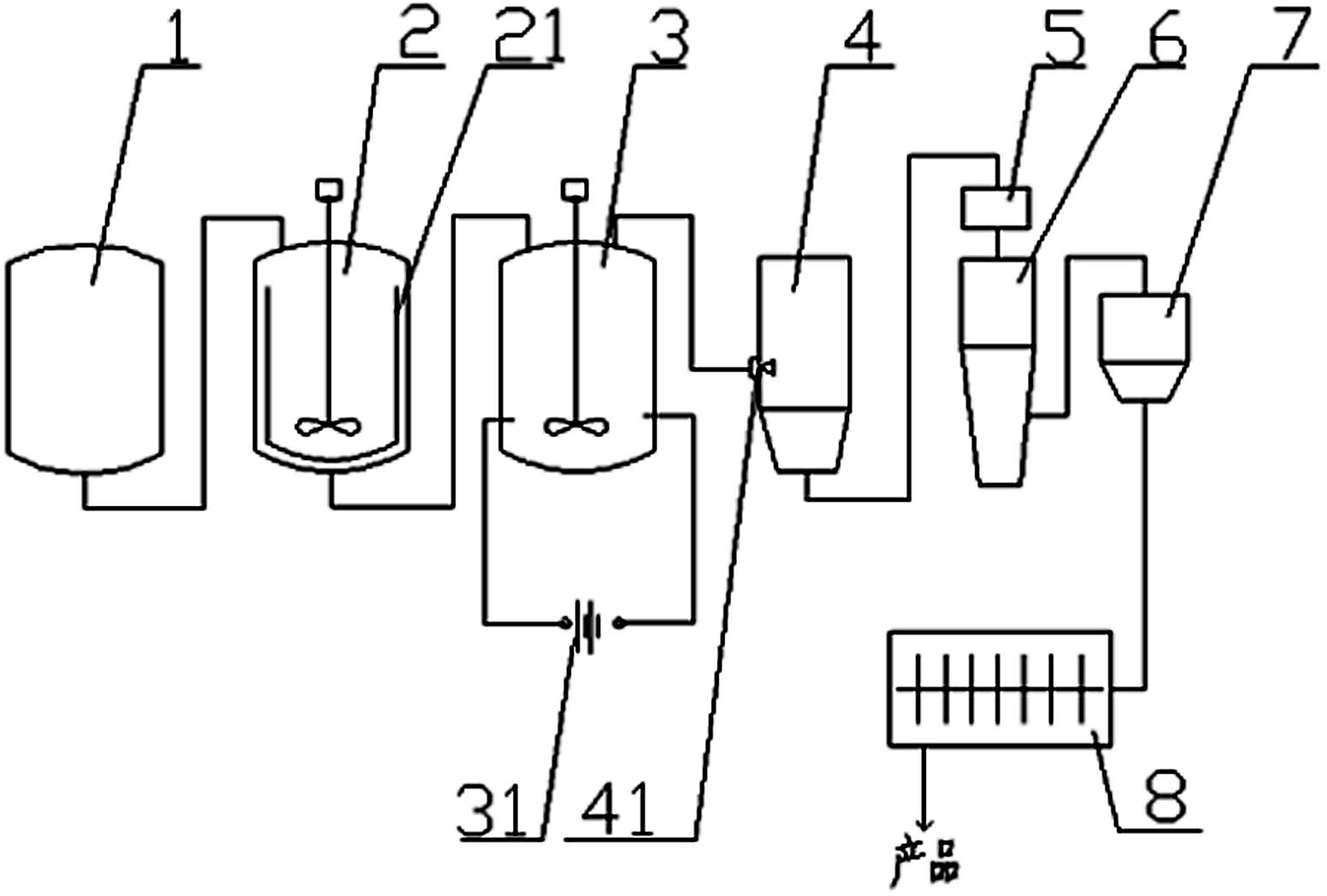

[0024] Will Fe 3 o 4 Put the powder into the high-pressure melting kettle, turn on the vacuum pump to evacuate the air in the kettle, then turn off the vacuum pump, and turn on the high-pressure pump to evacuate the CO 2 Inject into the high-pressure melting kettle, and adjust the temperature in the kettle to be higher than 31.1°C and the pressure to be higher than 7.4MPa. At this time, CO 2 It will be in a supercritical state, start the stirring device, and the stirring speed is 1000 r / min, and a filter screen 21 is installed in the high-pressure melting kettle 2. During the stirring process, particles less than or equal to 3.0 μm will pass through the filter screen 21;

[0025] The material (containing 50 grams of Fe 3 o 4 ) into the reaction kettle, the reaction kettle is equipped with electrodes and connected to the positive and negative electrodes of the DC power supply through wires, and then 20 grams of polyacrylate-styrene copolymer, 20 grams of charge regulator, 4 ...

Embodiment 2

[0029] The difference from Example 1 is that the material (containing 60 grams of Fe 3 o 4 ) after pumping into the reactor, then 15 grams of methyl acrylate, 5 grams of styrene, 1 gram of initiator AIBN, 10 grams of charge regulator, 6 grams of styrene-acrylic resin and 4 grams of iron oxide powder, Start the stirring device at a stirring speed of 1000 r / min. After the copolymerization reaction at a temperature of 80°C for 30 minutes, turn on the switch of the DC power supply and pass a direct current to the mixed material for 30 minutes. The direct current voltage is 800V. During the stirring process, electrostatic charges are generated on the surface of the particles.

[0030] All the other steps are basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com