Drying equipment and drying method for biological materials

A technology for biological materials and drying equipment, applied in drying chambers/containers, dryers, etc., can solve the problems of destroying biological materials and uneven dryness, and achieve the effects of uniform dryness, lasting and stable patterns, and improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

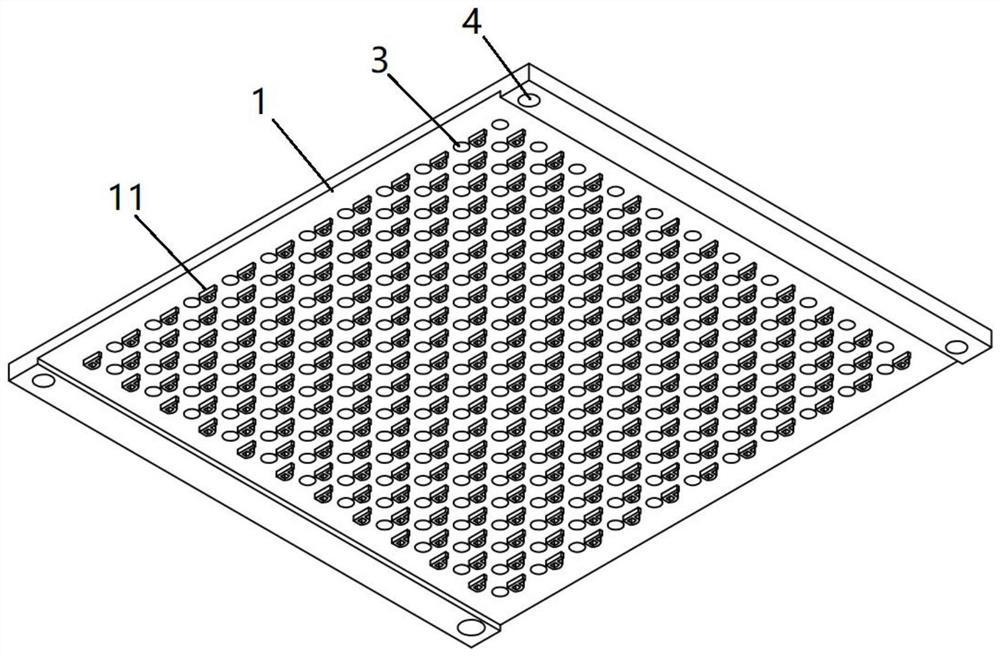

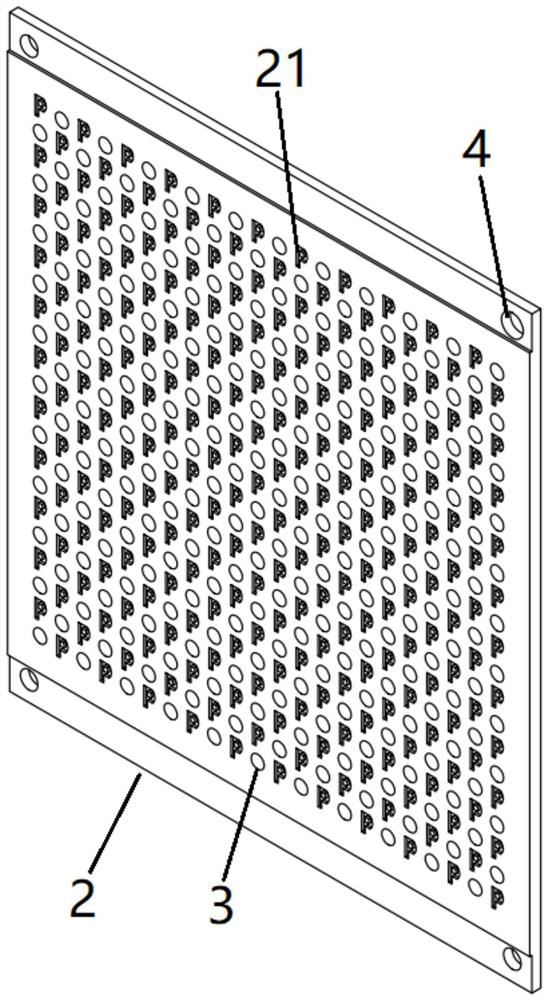

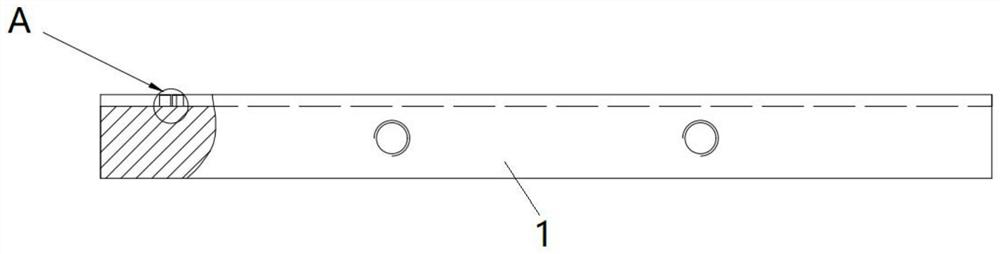

[0041] figure 1 Shown is a specific implementation of the drying equipment for biological materials, combined with figure 2, including a bearing structure 1 and a pressure-applying structure 2 for fixing biological materials through mutual snap fit. The bearing structure 1 has a plurality of first bearing parts 11 protruding from the bearing surface; the pressure applying structure 2 has a plurality of recessed grooves 21 far away from the pressure applying surface, and the grooves 21 are integrated with the first bearing parts 11. One corresponding setting, and the depth of the groove body 21 is less than the length of the first bearing part 11 protruding from the bearing surface, so that when the first bearing part 11 and the groove body 21 are clamped by an external force, An airflow gap is formed between the bearing surface and the pressing surface, which facilitates the passage of airflow during the ventilation and drying process of the biological material, so that the ...

Embodiment 2

[0049] The drying method of biological materials in the prior art is generally to place biological materials such as amniotic membrane and collagen membrane directly on a tray in an electric blast drying oven for drying, during which the biological materials shrink due to drying and form an uneven film. Using simple clamps can result in uneven drying of the biological material. Alternatively, the above-mentioned biological material is leveled, and the surroundings of the biological material are fixed on the plate-like device. Due to its fixation points around, the biological material shrinks when drying, and it is easy to tear in the middle part. In addition, after the biological material is dried, patterns such as patterns need to be pressed on it, and then processed by cutting, packaging, and sterilization. In addition, the patterns such as the pressed pattern will gradually flatten or even disappear with the passage of time due to the toughness of the biological material. ...

specific Embodiment approach

[0055] Another specific embodiment of the drying method of biological material comprises the following steps,

[0056] Lay the collagen membrane material that has been processed through steps such as washing and cross-linking on the bearing surface of the bearing structure 1, and clamp the groove body 21 of the pressure applying structure 2 and the first bearing part 11 of the bearing structure 1 in one-to-one correspondence, Put it into the positioning tool, or snap into other positioning devices, and the collagen membrane material is stuck between the bearing structure 1 and the pressure applying structure 2. Since the length of the first bearing portion 11 protruding from the bearing surface is greater than the depth of the groove body 21 , there is an airflow gap between the bearing surface and the pressing surface for air to pass through. Place the drying equipment with the collagen film in an electric blast drying oven (Boxun GZX-9023MBE), and dry it for 8 hours at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com