Pressure-adjustable uniform-dryness layered steam distributing tool

A pressure-adjustable and steam-distributing technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the amount of steam cannot enter the oil layer according to the design, the degree of production cannot be effectively improved, and steam drying is not considered. Problems such as the distribution of degrees, to improve the effect of steam injection, save manpower and material resources, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

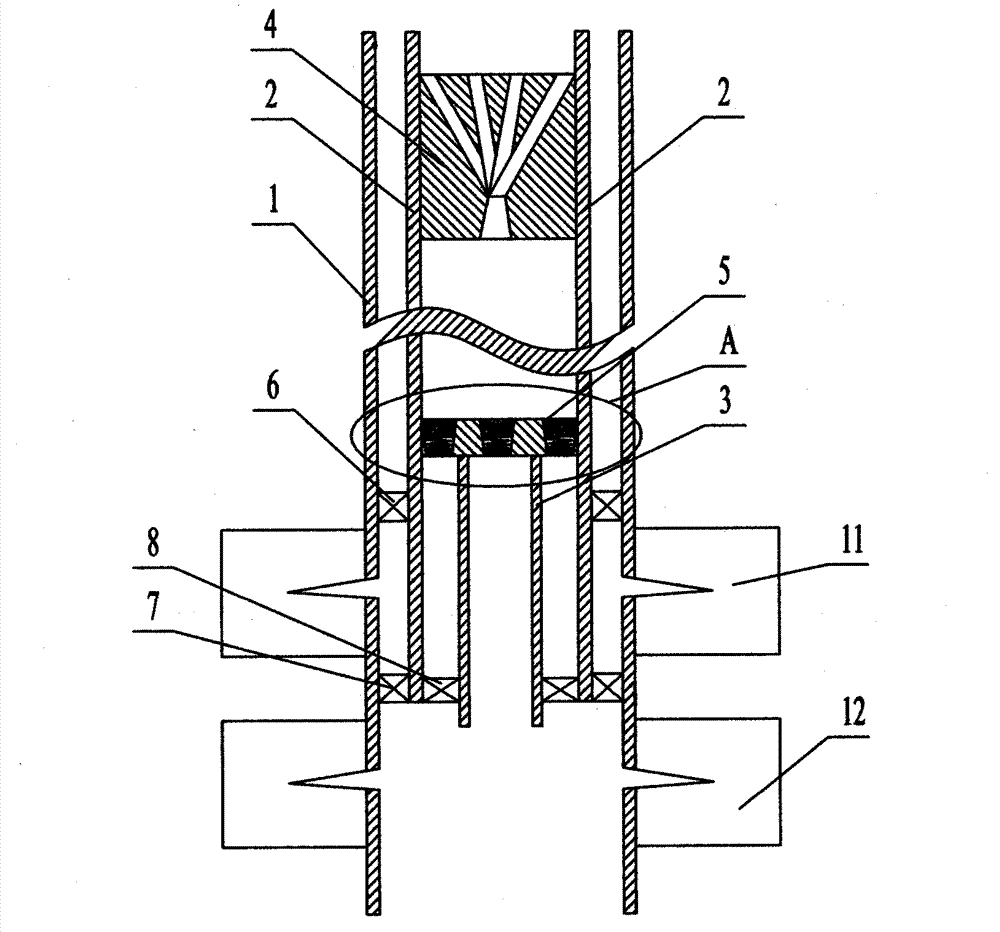

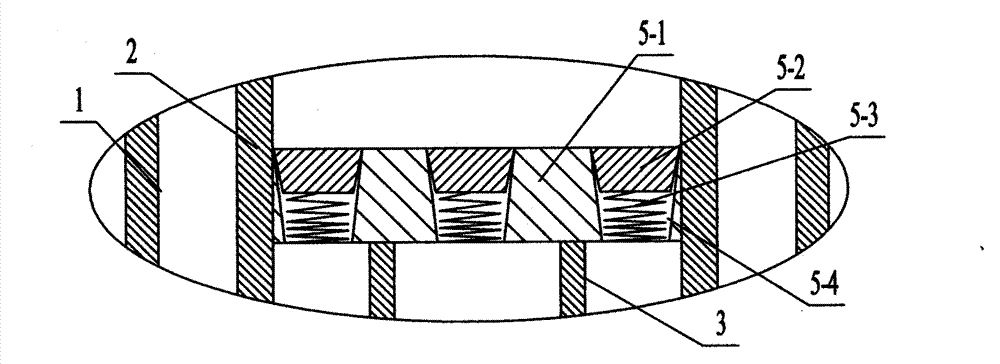

[0022] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a pressure-adjustable average dryness layered steam distribution tool in this embodiment includes a casing 1, an outer pipe 2, an inner pipe 3, a cyclone 4, a distributor 5, an upper packer 6, The lower packer 7 and the inner packer 8, the outer tube 2 is set on the outer side of the inner tube 3, the inner packer 8 is installed between the bottom of the inner tube 3 and the outer tube 2, and the outer tube 2 is set on the outer side. The upper packer 6 and the lower packer 7 are installed between the pipe 1, the outer pipe 2 and the casing 1, the distributor 5 is installed on the inner wall of the middle part of the outer pipe 2, and the upper end of the inner pipe 3 is connected with the distributor 5, and the outer A plurality of perforations are distributed on the pipe 2; a cyclone 4 is installed on the upper inner wall of the outer pipe 2, and the distributor 5 includes a dist...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 Describe this embodiment, the length of the outer pipe 2 of this embodiment is 6m, the outer diameter is 114.3mm, the inner diameter is 12.3mm, and the outer pipe 2 is made of steel pipe. Other compositions and connections are the same as in the second embodiment.

specific Embodiment approach 3

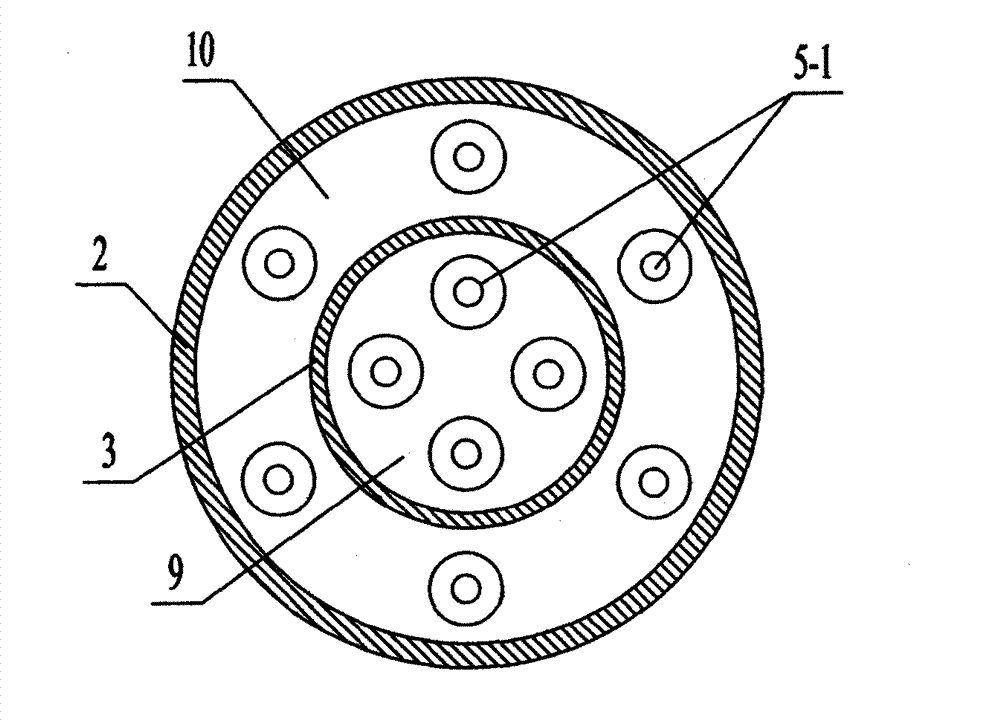

[0025] Specific implementation mode three: combination Figure 5 and Figure 6 To illustrate this embodiment, the outer tube 2 of this embodiment is uniformly provided with four rows of perforations along its circumferential direction, and the vertical distance L1 between two adjacent perforations in each row of perforations is 406mm. The number of perforations in the hole is fifteen, and the four rows of perforations are respectively defined as the first row of perforations 2-1, the second row of perforations 2-2, the third row of perforations 2-3 and the third row of perforations in the clockwise direction. Four rows of perforations 2-4, the vertical distance L2 between two adjacent perforations in the first row of perforations 2-1 and the second row of perforations 2-2 is 203mm, the third row of perforations 2- 3 and the vertical distance L2 between two adjacent perforations in the fourth row of perforations 2-4 is 203mm, and the adjacent two perforations in the first row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com