Centrally-mounted friction driving type curing machine

A roasting machine and transmission type technology, which is applied in the field of central friction transmission type roasting machines, can solve the problems of not being able to carry out multi-directional comprehensive drying at the same time, affecting product quality, and uneven dryness, etc., and achieves shortening drying time, simple structure, Dryness uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

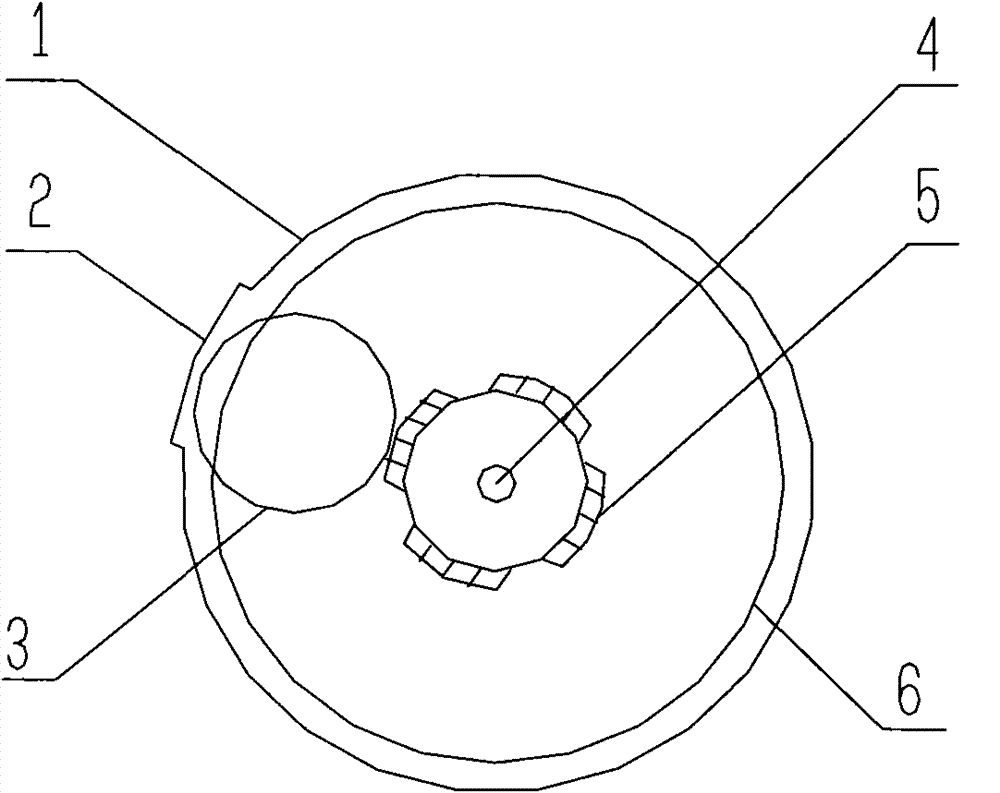

[0012] like figure 1 As shown, an embodiment of the middle-mounted friction transmission roaster of the present invention is given, which includes a circular box body 1 and a circular charging tray 2, and the circular box body 1 is provided with a charging tray inlet and outlet 3. Features There is a central shaft 4 in the center of the circular box body 1, the central shaft 4 is covered with an elastic friction roller 5, the circular material tray 2 is placed on the predetermined track 6 outside the elastic friction roller 5, and the circular material tray 2 One end is close to the inner wall of the circular box body 1, and the other end is close to the elastic friction roller 5.

[0013] When working, use the power of the motor to drive the sprocket of the central shaft 4 through the chain to drive the elastic friction roller 5 to run, use the elastic friction roller 5 as the main drive, and use the friction between the circular material tray 2 and the elastic friction rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com