Rock mass dry-wet cycle damage monitoring system and method in chemical corrosion environment

A dry-wet cycle, chemical corrosion technology, used in weather resistance/light resistance/corrosion resistance, measurement devices, scientific instruments, etc. problems, to avoid particle deposition or water accumulation, improve weighing accuracy, and improve dryness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

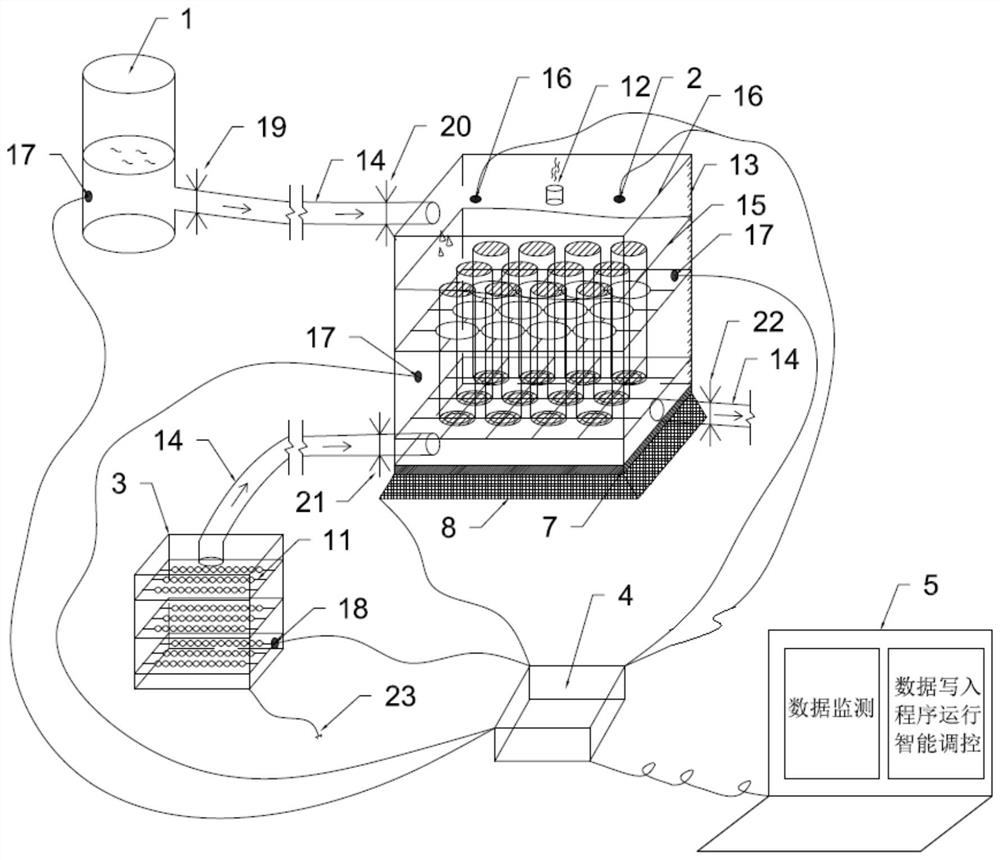

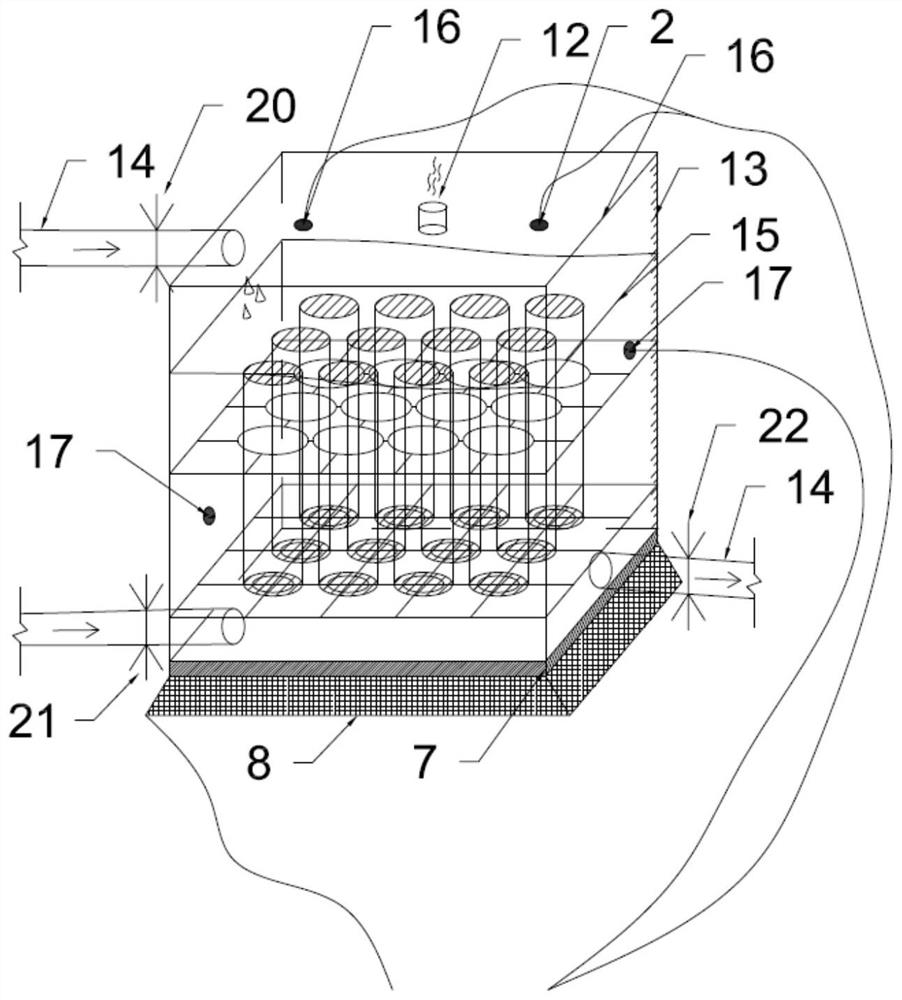

[0040] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] A) system structure

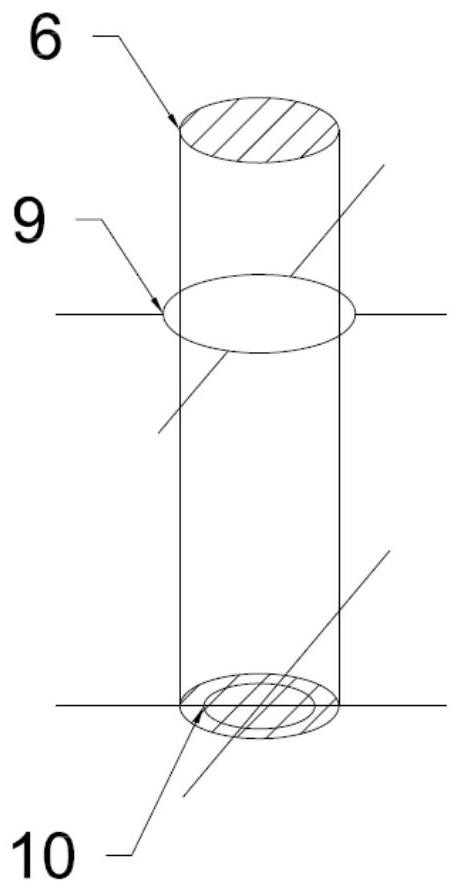

[0042] refer to Figure 1 ~ 3As shown, a rock mass dry and wet circulation damage monitoring system in a chemical corrosion environment, including a dry and wet circulation test chamber, the dry and wet cycle test chamber is placed on the wearing stage; the dry wet circulation test chamber is provided with rock samples The bracket is provided with a rigging hole (for drying moisture during drying);

[0043] Also packaged chemical solution configuration container and dry heat source supply box; the chemical solution is configured to communicate with the dry and wet cycle test chamber through the liquid pipe, the drying heat source supply box through the air tube and the dry and wet cycle test chamber Connect; the drainage tube, the inlet tube and the weapper are respectively provided with respective valves;

[0044] It a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com