Distilled grain airflow dryer

A technology of airflow dryer and distiller's grains, applied in dryer, drying, drying of solid materials, etc., can solve the problems of short drying time, uneven particle size of wet distiller's grains, and high temperature of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

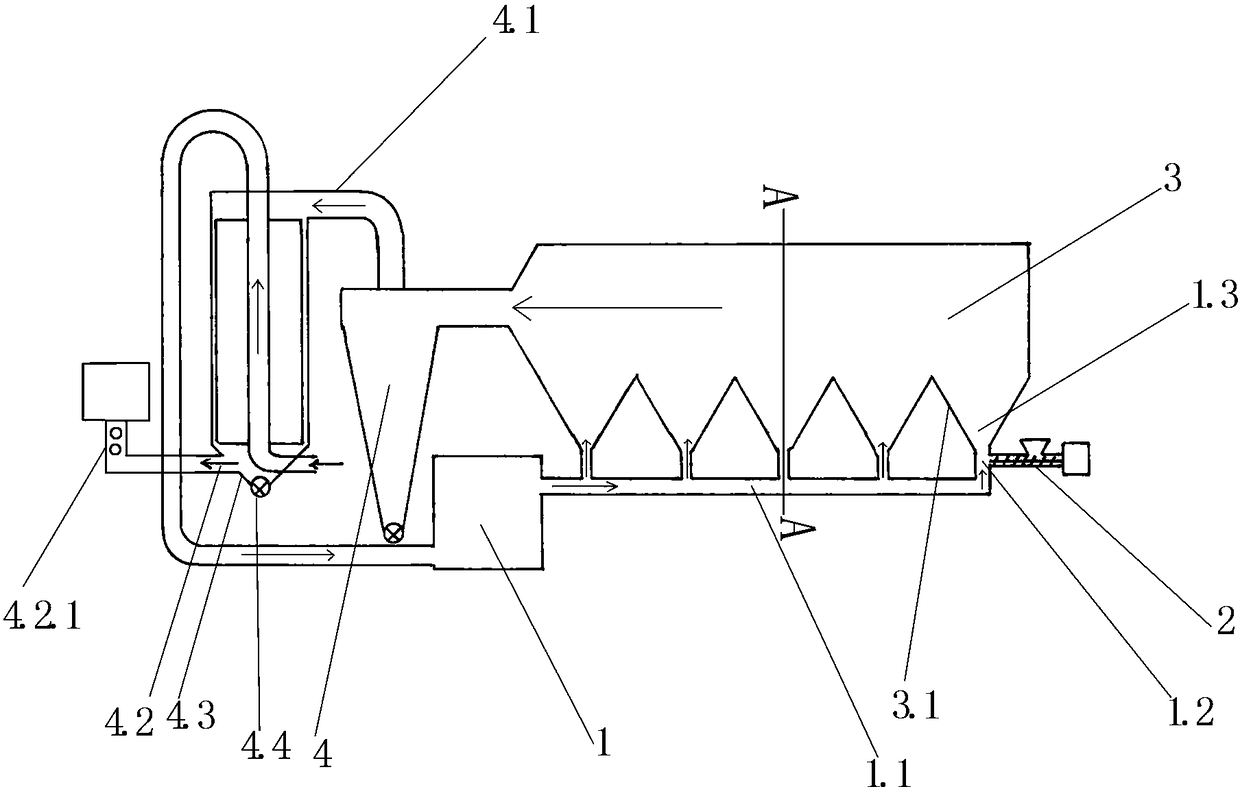

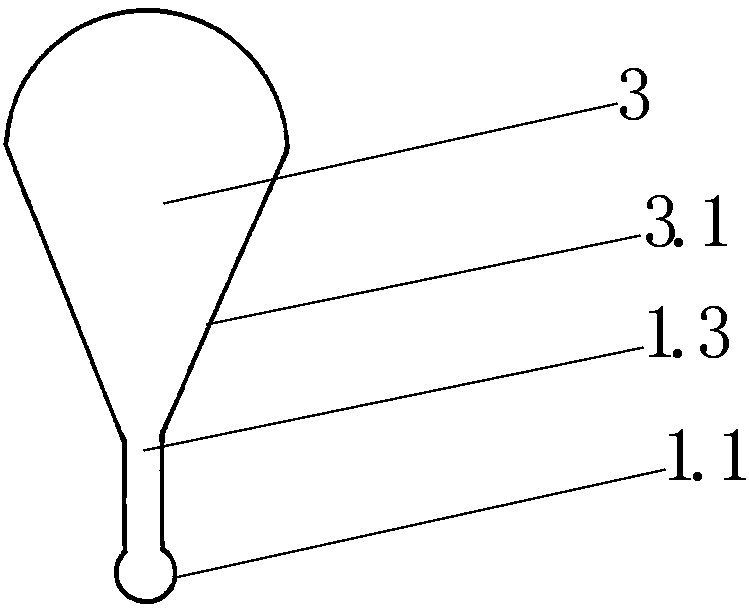

[0010] exist figure 1 , 2 Among them, the present invention provides a distiller's grain airflow dryer, which is a machine specially used for drying distiller's grains, which includes a hot air blower, a screw conveyor, a drying chamber, and a cyclone unloader. It is characterized in that: The drying chamber (3) of the distiller's grain airflow dryer is a long container placed obliquely. The cross section of the drying chamber (3) is fan-shaped. The high end of the drying chamber (3) is sealed. The drying chamber (3) The lower upper part of the lower end is connected with the air inlet pipe of the cyclone unloader (4); there are multiple funnels (3.1) in the lower part of the drying chamber (3), and multiple hot air blowers ( 1) Blowing outlet (1.3), the first hot air blower (1) blowing outlet (1.3) under the high end of the drying chamber (3) is larger and connected with a three-way pipe (1.2), the horizontal of the three-way pipe (1.2) There is a screw conveyor (2) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com