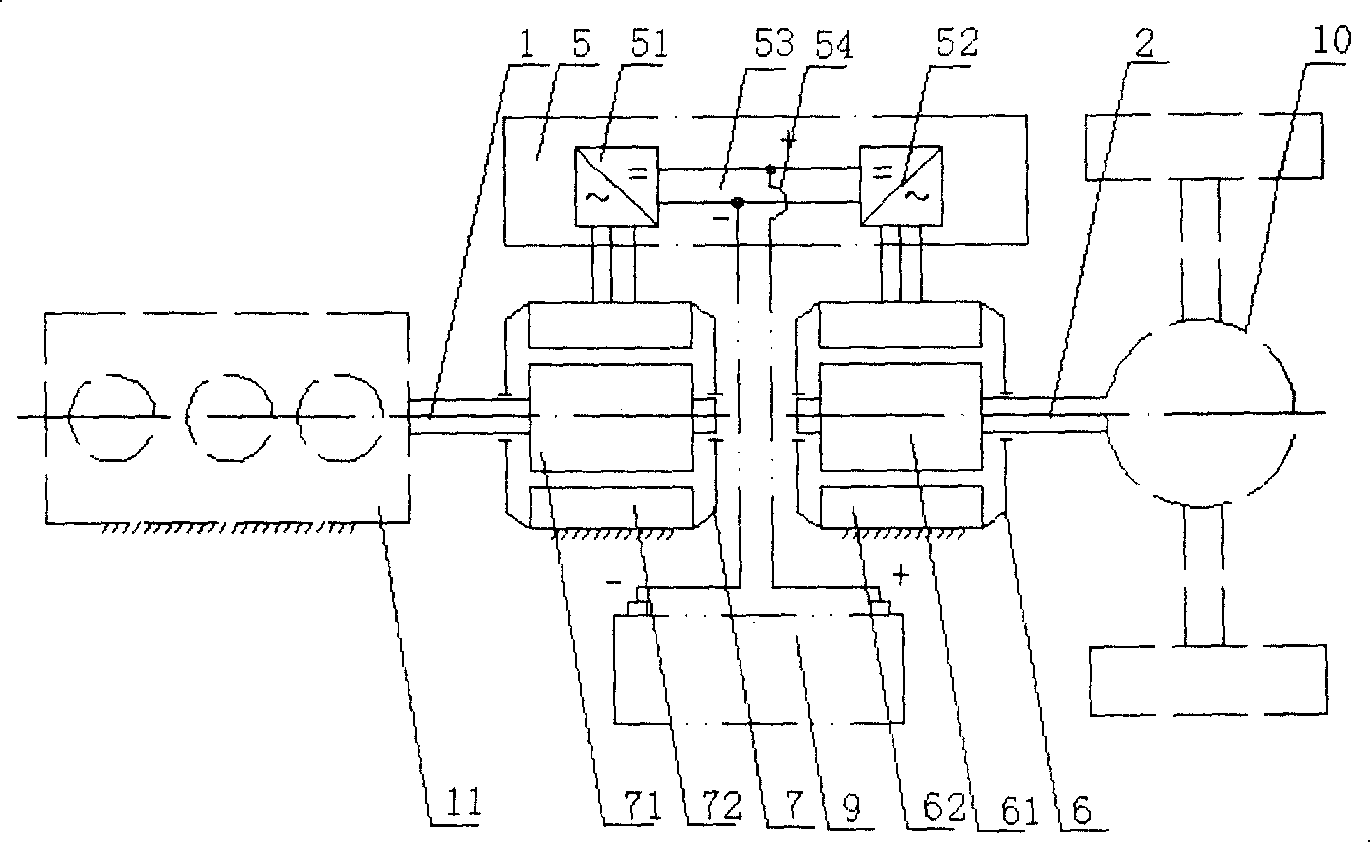

Electromagnetic coupling variable-speed drive system

A technology of infinitely variable speed and electromagnetic coupling, applied in electromechanical transmission devices, control systems, electric components, etc., can solve the problems of complex equipment and high manufacturing costs of power confluence and transmission systems, and achieve reduced rated power capacity, improved overall efficiency, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

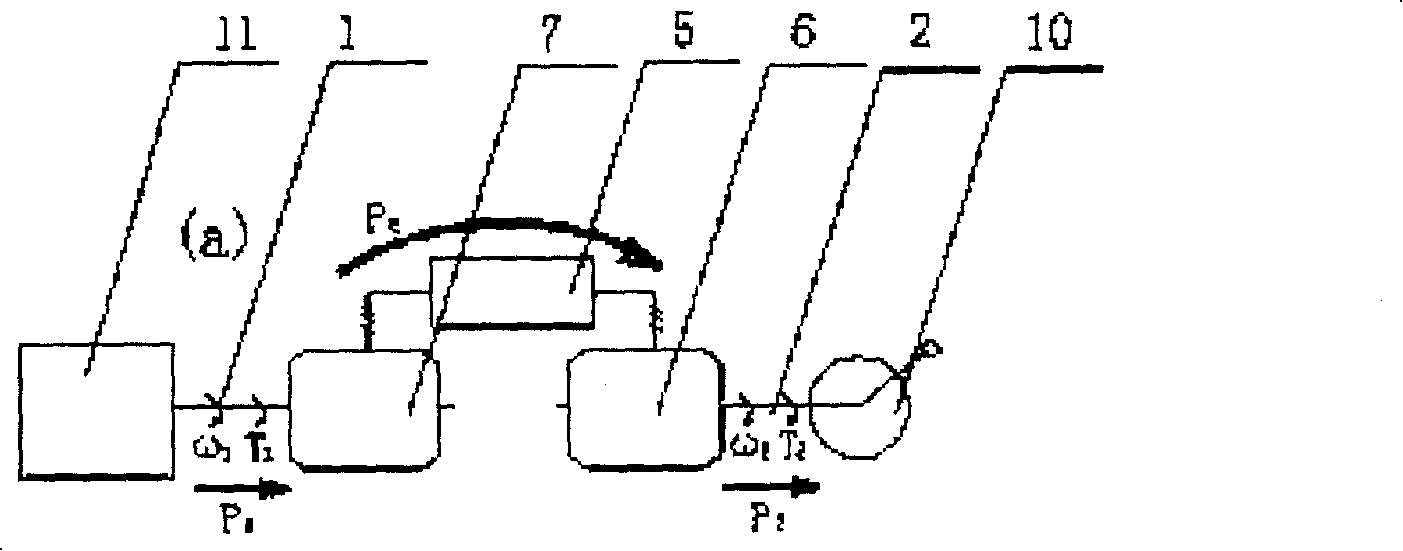

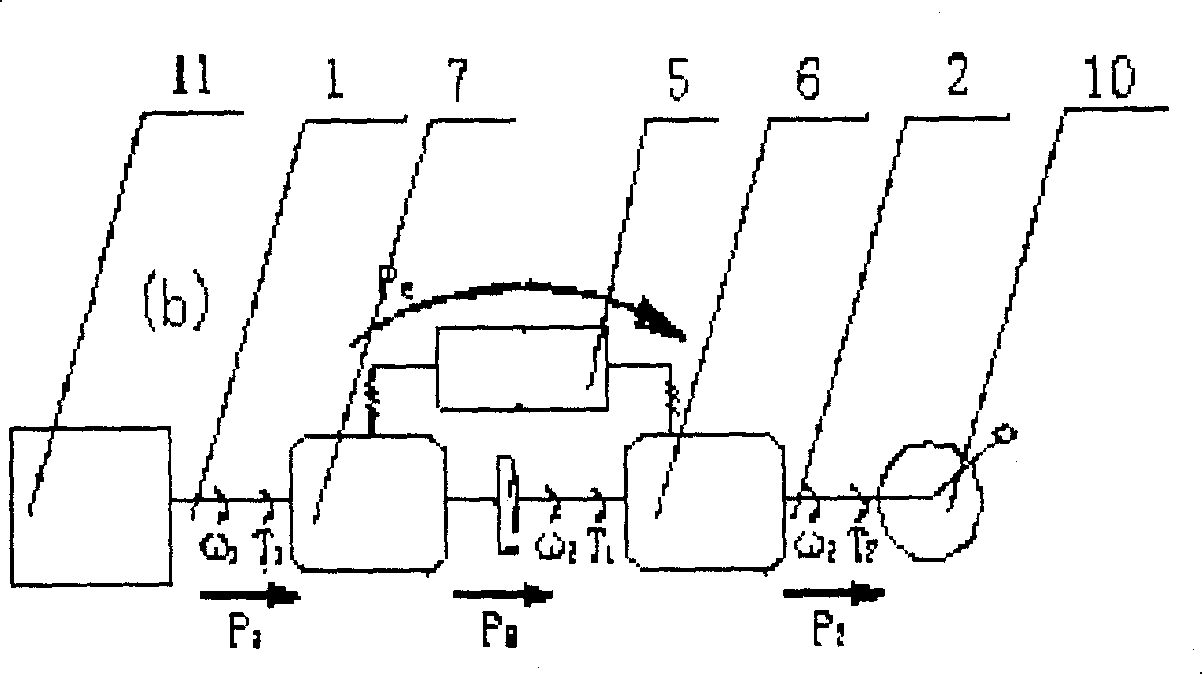

Embodiment 1

[0027] Such as Figure 5 As shown, the input shaft 1, the output shaft 2 and the base 3 form a mutual supporting relationship through bearings. The rotor 71 is fixed on the input shaft 1 and placed in the inner cavity of the cup-shaped rotor 67 together with its axial coil winding with an air gap. The cup-shaped rotor 67 is fixedly connected to the output shaft 2 . The stator 62 is fixed on the frame 3 and cooperates with the outer surface of the cup-shaped rotor 67 with an air gap. The additional magnetic modulation coil 4 is a DC coil wound circumferentially in the annular groove of the iron core of the stator 62, and is connected to the power electronic controller 5 through wires. The direction of the current of the additional magnetic modulation coil 4 determines whether the permanent magnet cup rotor 67 is magnetized or weakened, and the magnitude of the current determines the magnitude of this magnetic modulation effect. The induction primary coil 81 and the induction ...

Embodiment 2

[0032] The prime mover 11 in the first embodiment is connected with the output shaft 2, the load 10 is connected with the input shaft 1, and other structures are completely the same as the first embodiment. In this embodiment, only the input shaft in embodiment 1 is converted into an output shaft, and the output shaft is converted into an input shaft, so that the effect obtained is the same as that in embodiment 1.

Embodiment 3

[0034] The non-contact current collector composed of the induction primary coil 81 and the induction secondary coil 82 in Embodiment 1 is replaced by a conventional contact brush slip ring current collector. This can reduce the cost, weight and system complexity, but the system reliability has decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com