Grain stillage drying device

A technology of drying device and distiller's grains, which is applied in drying, drying machine, drying gas arrangement, etc., and can solve the problems of no recycling, high humidity, and high temperature of waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

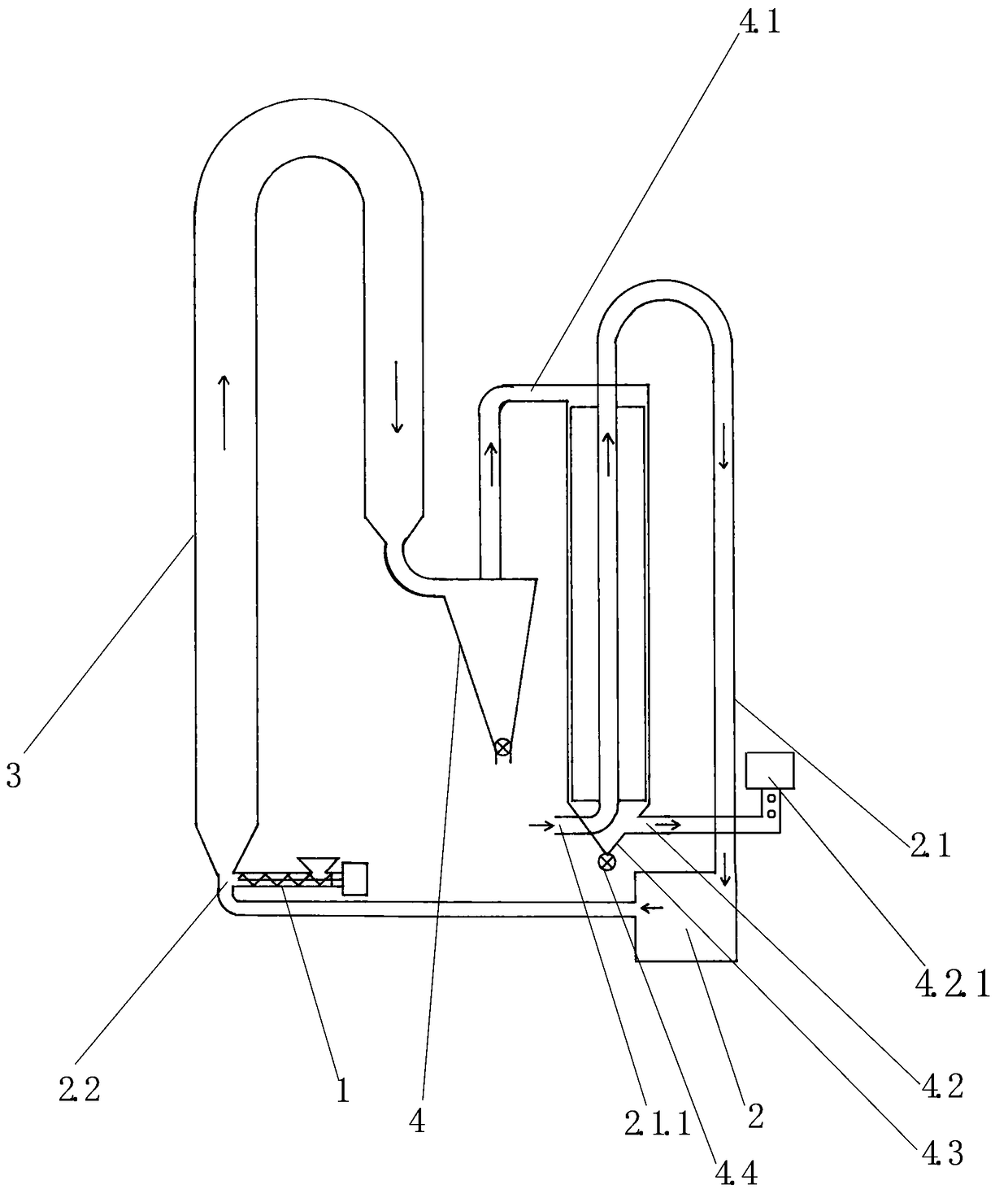

[0008] In the figure, the invention provides a distiller's grain drying device, which is a mechanical device specially used for distiller's grain drying. It includes a feeder, a hot air blower, a drying tower, and a cyclone unloader. The lower part of the drying tower (3) has a feed port of the screw conveyor (1), and there is a hot air blower outlet (2.2) under the feed port of the screw feeder (1), and the air outlet of the drying tower (3) is connected to There is a cyclone unloader (4), the air outlet pipe of the cyclone unloader (4) is wrapped with a hot air inlet pipe (2.1) with fins, and there is a liquid collecting bucket at the lower part of the air outlet pipe (4.1) of the cyclone unloader (4.3), there is a liquid discharge valve (4.4) under the liquid collecting bucket (4.3), there is an air outlet at the lower part of the air outlet pipe (4.1) of the cyclone unloader, and there is an advertising air pipe (4.2.1) on the air outlet to send it to both sides of the road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com