Vertical ultralow-temperature freezer

An ultra-low temperature freezing and vertical technology, which is applied in the field of cryogenic boxes and ultra-low temperature vertical freezing boxes, can solve the problems of inconvenient storage of items in horizontal freezing boxes, great influence on cooling effect, and difficult maintenance and maintenance, and achieve good cooling effect, Flexible aspect layout, the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

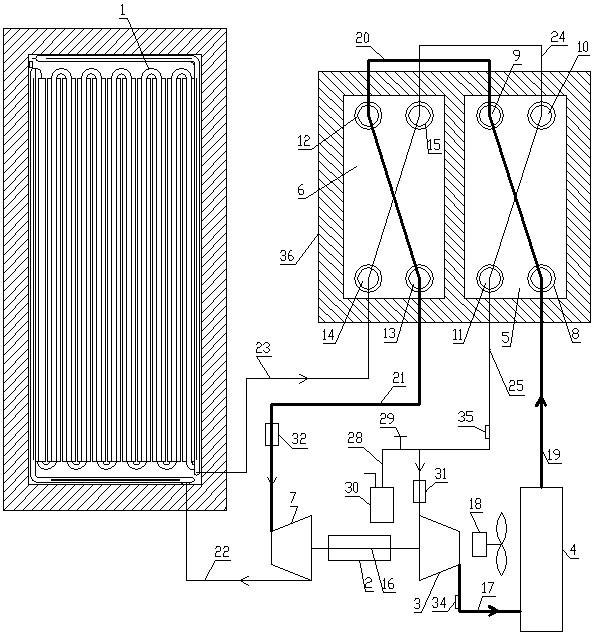

[0031] Such as Figure 1 to Figure 3 As shown, a kind of vertical ultra-low temperature freezer of the present invention comprises a vertical box body, is provided with in the vertical box body and is used for releasing the cooling device 1 of cooling capacity in the vertical box body, and the vertical box body is a low-temperature storage container, It is a conventional technology, not shown in the figure.

[0032] The vertical box is equipped with a nitrogen refrigeration mechanism; the nitrogen refrigeration mechanism includes a high-speed motor 2, a turbo compressor 3, an aftercooler 4, a first regenerator 5, a second regenerator 6 and an expander 7;

[0033] The first regenerator 5 has a first high-temperature inlet 8, a first high-temperature outlet 9, a second low-temperature inlet 10, and a second low-temperature outlet 11; the first high-temperature inlet 8 is connected to the second A high-temperature outlet 9, a second low-temperature inlet 10 connected to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com