Brayton refrigeration cycle low-temperature box

A refrigeration cycle and low temperature box technology, applied in cooling fluid circulation devices, refrigerators, refrigeration components, etc., can solve the problems of low operation efficiency, complex control system, refrigerant pollution, etc., to improve heat exchange efficiency, system stability and reliability , the effect of enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

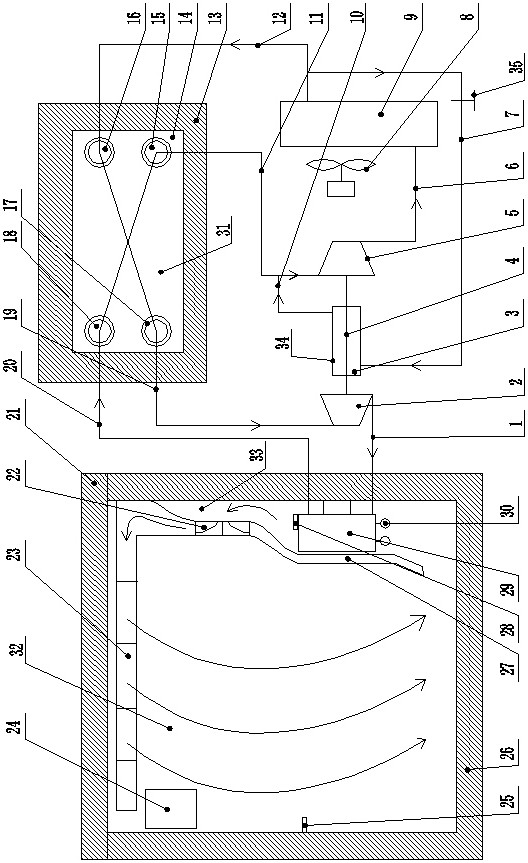

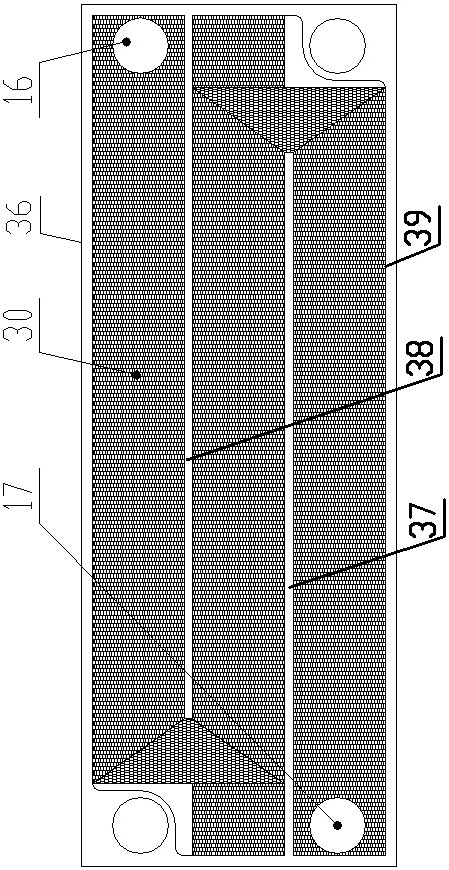

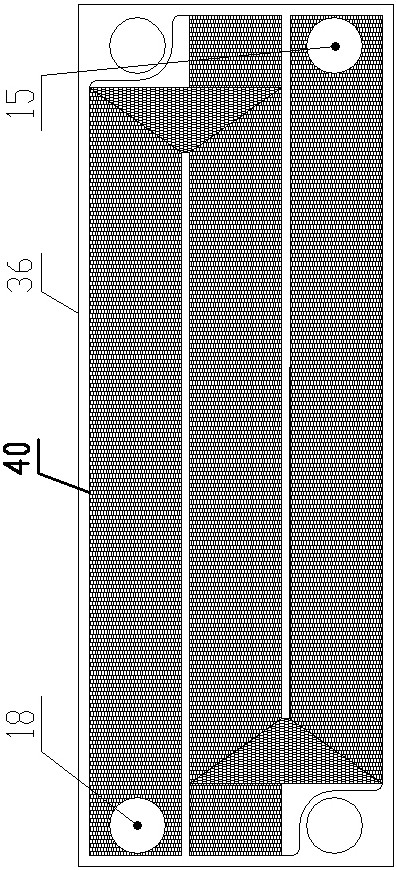

[0030] Such as Figure 1 to Figure 3 As shown, the present invention provides a Brayton refrigeration cycle low-temperature box, including a box body 26, a regenerator 31 for heat exchange between low-temperature nitrogen and high-temperature nitrogen, a turbo compressor 5, an expander 2, and an aftercooler 9 , with cooler 29 and high-speed motor 3, one side of the box body 26 is provided with an air duct cover plate 27, and the air duct cover plate 27 divides the inner cavity of the box body 26 into a storage space 32 and an air duct 33; the top of the box body 26 is provided with several The air outlet 23 for supplying air to the storage space 32 in the box body 26, the bottom end of the air duct 33 communicates with the storage space 32, the lower part of the air duct 33 is provided with the cooler 29, and the air duct cover plate 27 is installed There is a circulating fan for generating circulating air in the box body 26 (the circulating fan is a centrifugal fan);

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com