Concentric pipe layered steam injection system and method

A technology of layered steam injection and concentric tubes, applied in the field of steam injection system, can solve the problems that thermal stress cannot be released and affect the steam injection effect, etc., and achieve the effect of improving steam injection effect, good heat compensation, and uniform steam dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

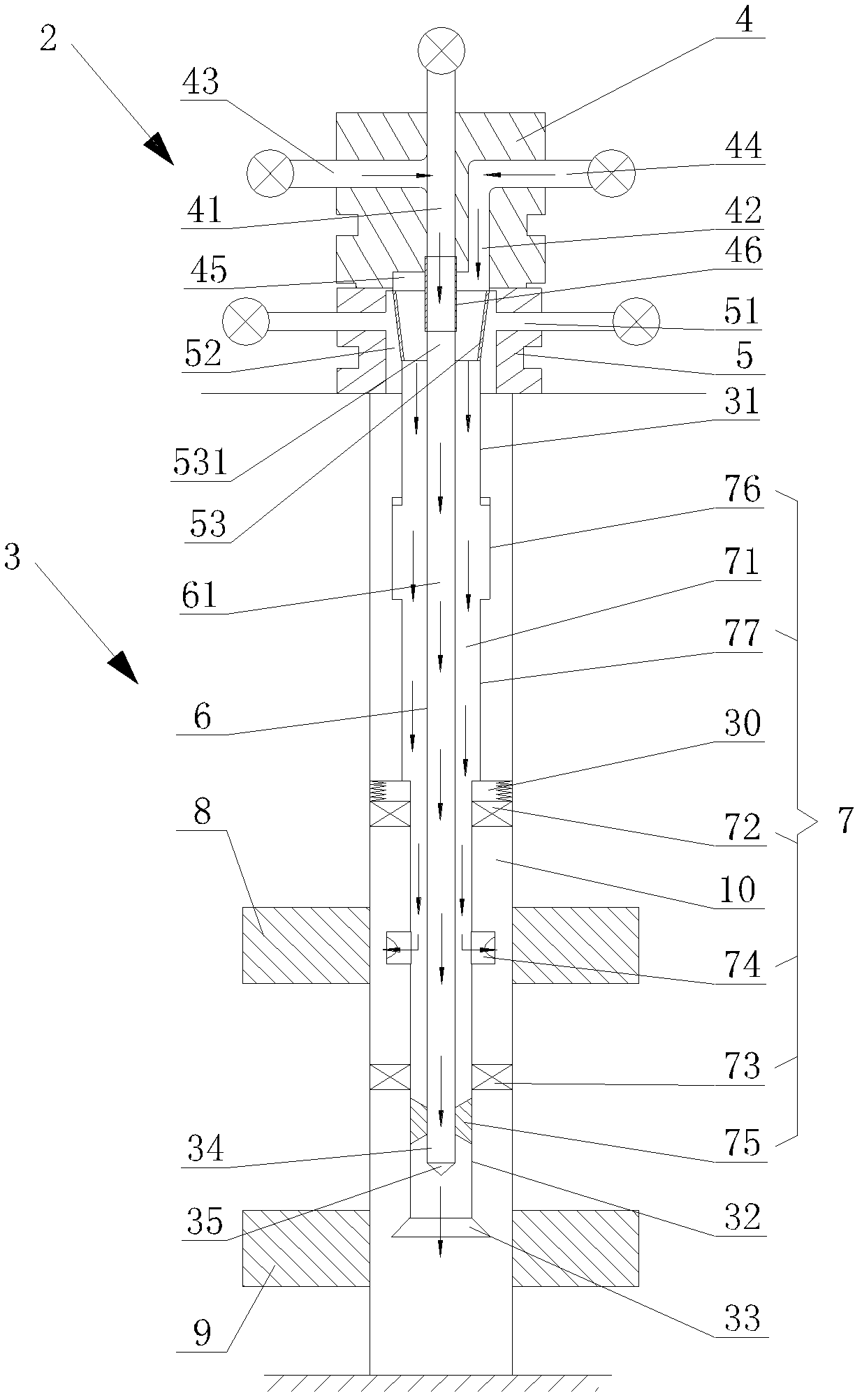

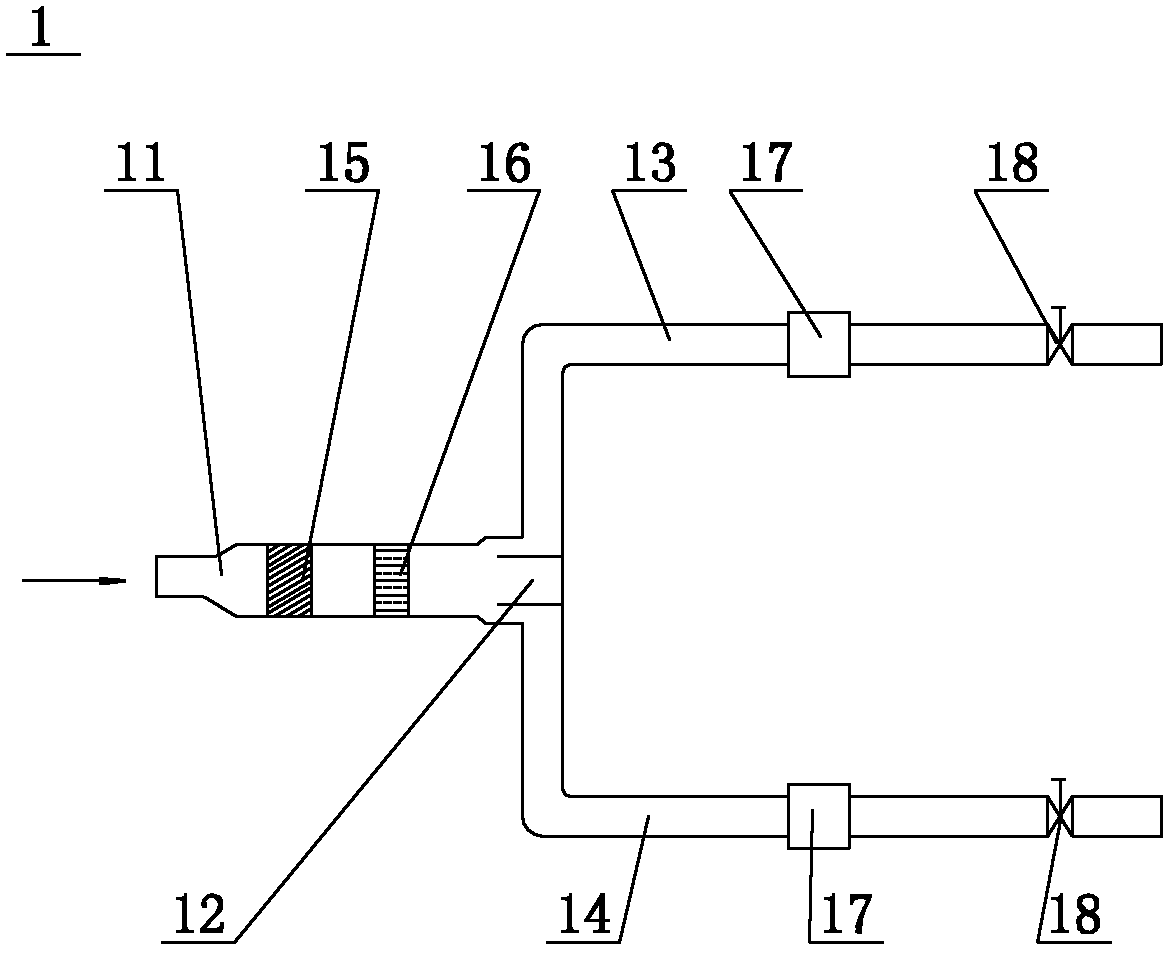

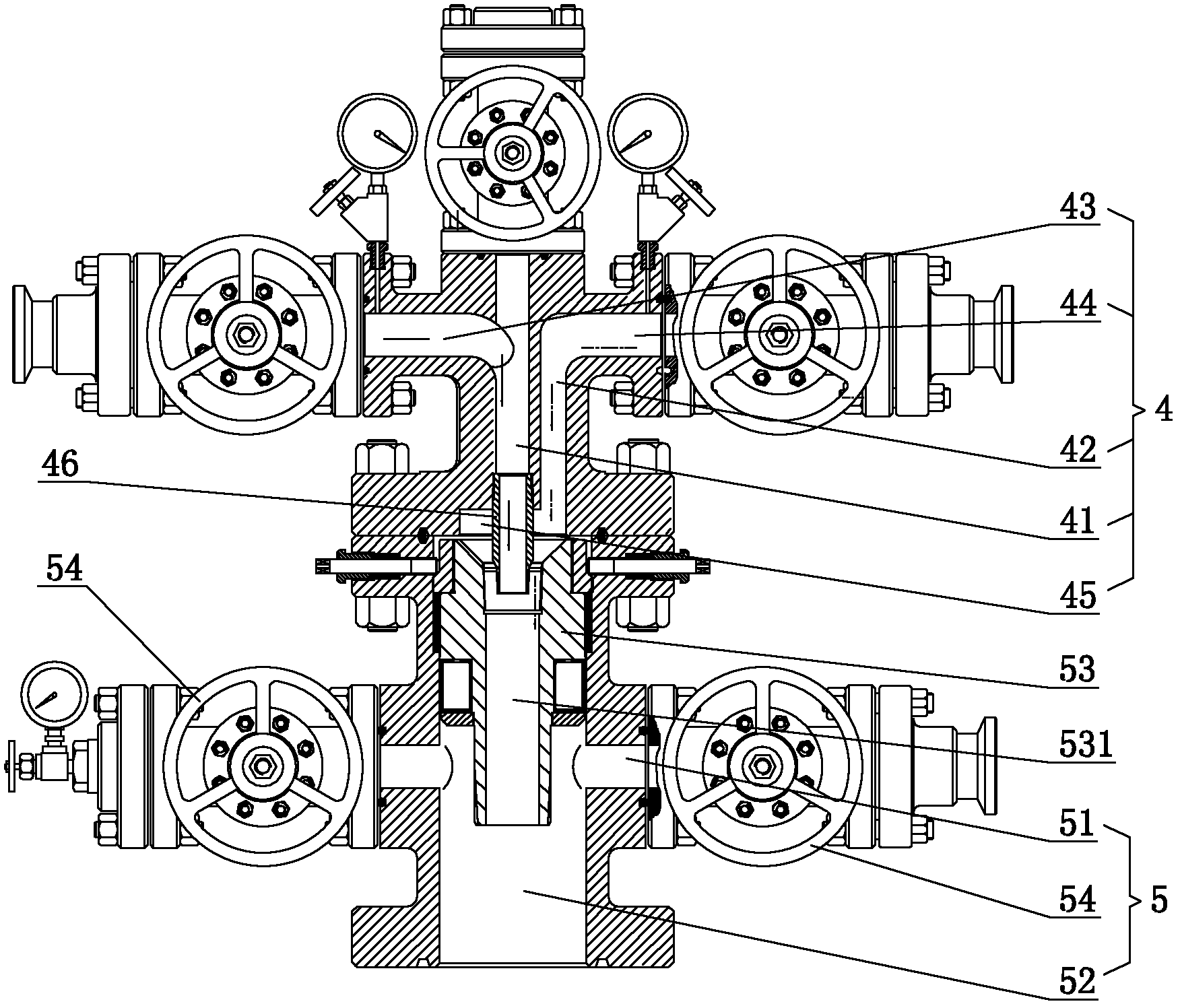

[0047] Such as figure 1 , 2 As shown, the present invention provides a concentric tube layered steam injection system, which includes a steam distribution device 1 , a wellhead device 2 and a concentric layered steam injection string 3 . Wherein, the steam distribution device 1 has a steam inlet channel 11, and the outlet end of the steam inlet channel 11 is respectively connected with a first steam outlet channel 13 and a second steam outlet channel 14 through an equal dryness distribution chamber 12, and at the steam inlet The channel 11 is provided with a swirler 15 and a phase mixer 16 sequentially along the steam inflow direction; the wellhead device 2 includes a double-pipe cross 4, and the double-pipe cross 4 is provided with an internal steam injection channel 41, and the inner The periphery of the steam injection flow channel 41 is provided with an arc-shaped outer steam injection flow channel 42, and the side walls of the double-pipe four-way 4 are respectively prov...

Embodiment approach 2

[0072] Such as Figure 12 As shown, the present invention also provides a concentric tube layered steam injection method, which uses the above-mentioned concentric tube layered steam injection system, which includes the following steps:

[0073] a) Steam distribution: inject steam into the steam inlet channel 11 of the steam distribution device 1, and after the steam flows through the cyclone 15 and the phase mixer 16, steam with uniform dryness is formed, and the steam with uniform dryness is distributed through equal dryness The chamber 12 flows out from the first steam outlet channel 13 and the second steam outlet channel 14 respectively;

[0074] b) Steam delivery: connect the first steam outlet channel 13 of the steam distribution device 1 with the internal steam injection port 43 of the wellhead device 2, connect the second steam outlet channel 14 of the steam distribution device 1 with the external steam injection port 44 of the wellhead device 2 Connected; the steam w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com