Herbarium making method

A technology of wax leaf specimens and production methods, which are applied in the fields of botanical equipment and methods, preservation and application of plants, etc., can solve the problems of easy deformation of table paper, easy absorption of moisture and mildew on table paper, and difficulty in distinguishing and repairing, so as to prevent specimens from being repaired. Scattered, easy to distinguish and repair, the effect of uniform dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

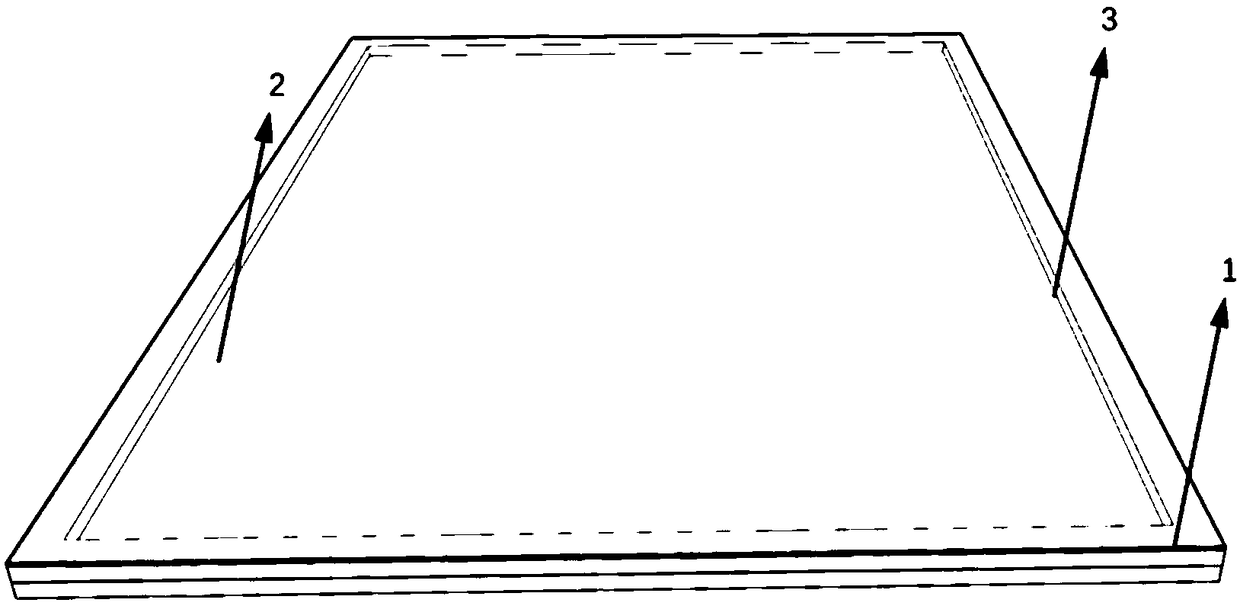

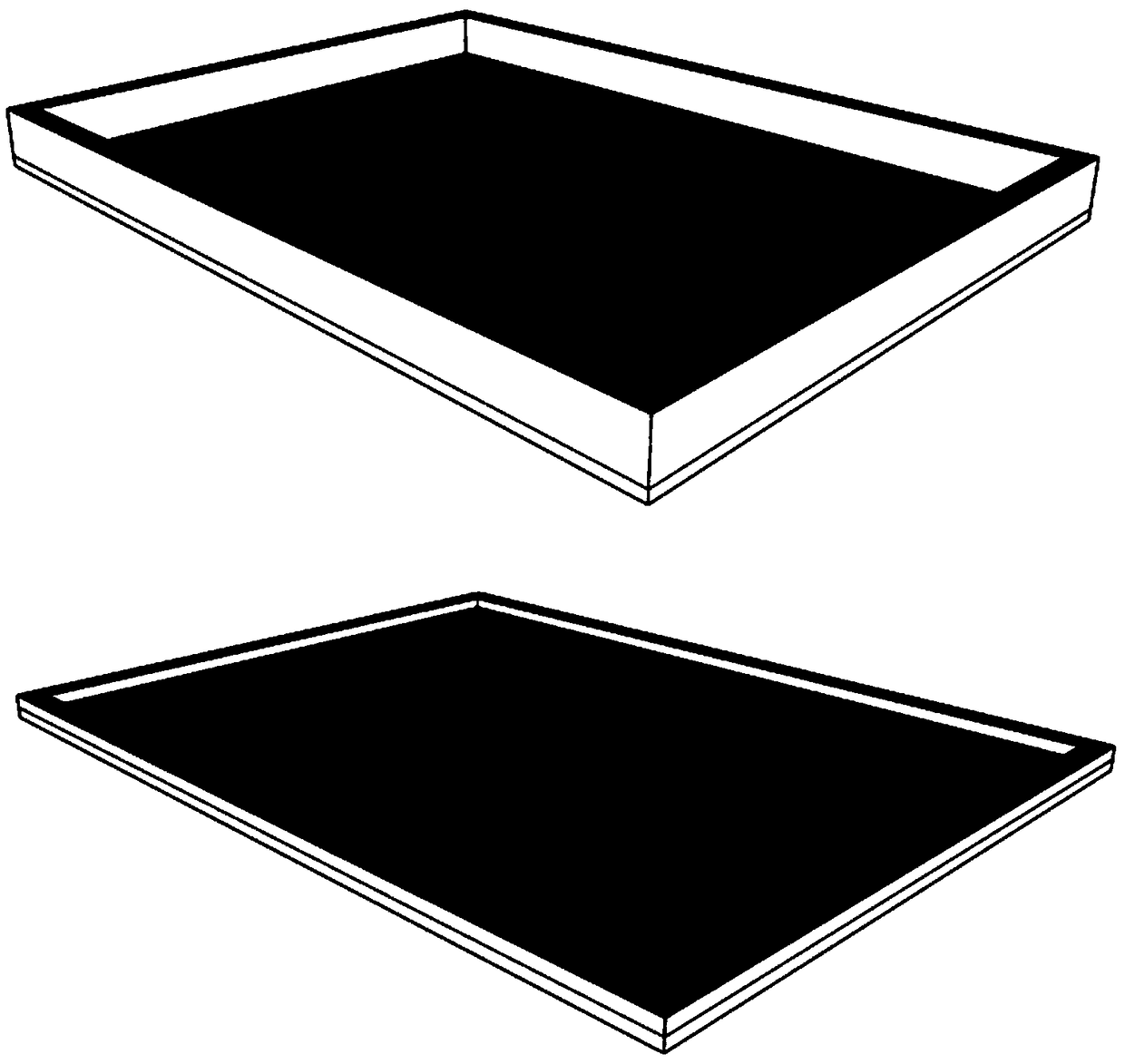

[0020] Such as Figure 1-3 Shown, a kind of preparation method of wax leaf specimen of plant, its step comprises:

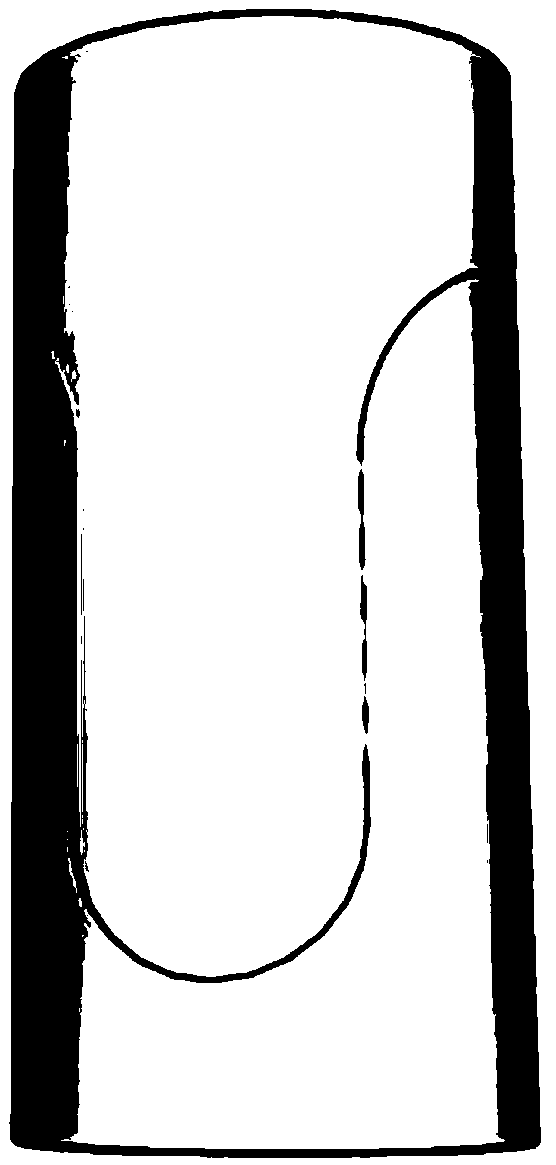

[0021] (1) Use U-shaped scissors to disassemble the plants to be prepared according to the branches, leaves, and flowers and / or fruits, so that the incisions of the disassembled parts present U-shaped and corresponding protrusions;

[0022] (2) Select the appropriate tablet 5 from the polygonal combined tablet press set, press the branches, leaves and flowers on the bottom plate 4 respectively, fix them with rubber bands and wait for air drying, or place them in a blast drying oven at 40°C For drying, the fruit is fixed in the middle with two breathable metal plates, and then dried in a blast drying oven at 40°C; the polygonal combined tablet pressing set includes square bottom plates of different sizes, and different shapes and sizes The pressing sheet is made of glass sheet with a thickness of less than 0.8mm, and the bottom plate is made of glass sheet with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com