Picking and baking method for reviving tobacco in high-altitude tobacco area

A high-altitude, green tobacco technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of easy browning of dry leaves, loss of use value, poor grade of tobacco leaves, etc., and achieves easy yellowing and dehydration. Improves grade, accelerates water loss and yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

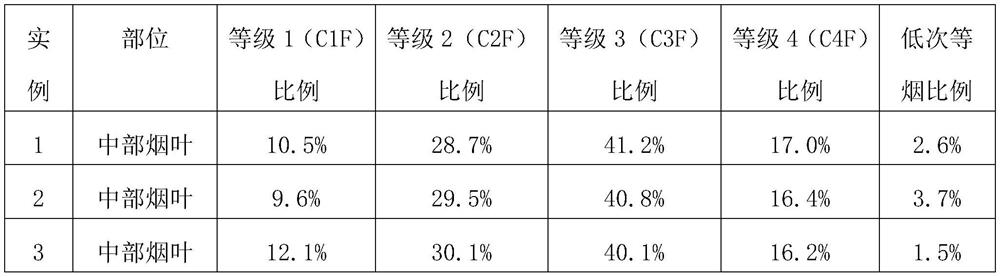

Examples

Embodiment 1

[0025] A method for collecting and roasting green tobacco in a high-altitude tobacco area, comprising the following steps:

[0026] (1) Harvesting

[0027] When the weather is fine, the tobacco leaves are harvested when they show the characteristics of yellowing and maturity again under the conditions of sunlight and ventilation; when the weather is continuously cloudy and rainy, the tobacco leaves are at risk of being water-dried, so they should be harvested immediately;

[0028] (2) smoke

[0029] When the tobacco leaves are loaded into the kang, the distance between the poles of the kang is 28cm;

[0030] (3) Yellowing and stable temperature section

[0031] After filling the tobacco, heat it immediately to make the dry bulb temperature reach 39°C and keep it at this temperature, while keeping the difference between the dry bulb temperature and the wet bulb temperature at 4°C until the tobacco leaves turn yellow completely;

[0032] During the process of heating to make ...

Embodiment 2

[0040] A method for collecting and roasting green tobacco in a high-altitude tobacco area, comprising the following steps:

[0041] (1) Harvesting

[0042] When the weather is fine, the tobacco leaves are harvested when they show the characteristics of yellowing and maturity again under the conditions of sunlight and ventilation; when the weather is continuously cloudy and rainy, the tobacco leaves are at risk of being water-dried, so they should be harvested immediately;

[0043] (2) smoke

[0044] When the tobacco leaves are loaded into the kang, the distance between the poles of the kang is 25cm;

[0045] (3) Yellowing and stable temperature section

[0046] After filling the tobacco, heat it immediately to make the dry bulb temperature reach 40°C and keep it at this temperature, while keeping the difference between the dry bulb temperature and the wet bulb temperature at 3°C until the tobacco leaves turn yellow completely;

[0047] During the process of heating to mak...

Embodiment 3

[0055] A method for collecting and roasting green tobacco in a high-altitude tobacco area, comprising the following steps:

[0056] (1) Harvesting

[0057] When the weather is fine, the tobacco leaves are harvested when they show the characteristics of yellowing and maturity again under the conditions of sunlight and ventilation; when the weather is continuously cloudy and rainy, the tobacco leaves are at risk of being water-dried, so they should be harvested immediately;

[0058] (2) smoke

[0059] When the tobacco leaves are loaded into the kang, the distance between the poles of the kang is 30cm;

[0060] (3) Yellowing and stable temperature section

[0061] After filling the tobacco, heat it immediately to make the dry bulb temperature reach 40°C and keep it at this temperature, while keeping the difference between the dry bulb temperature and the wet bulb temperature at 3°C until the tobacco leaves turn yellow completely;

[0062] During the process of heating to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com