Processing method of sweet potato and passion fruit cakes

A processing method and technology of passion fruit are applied in the field of fruit cake processing to achieve the effects of increasing flavor, improving juice yield and improving peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

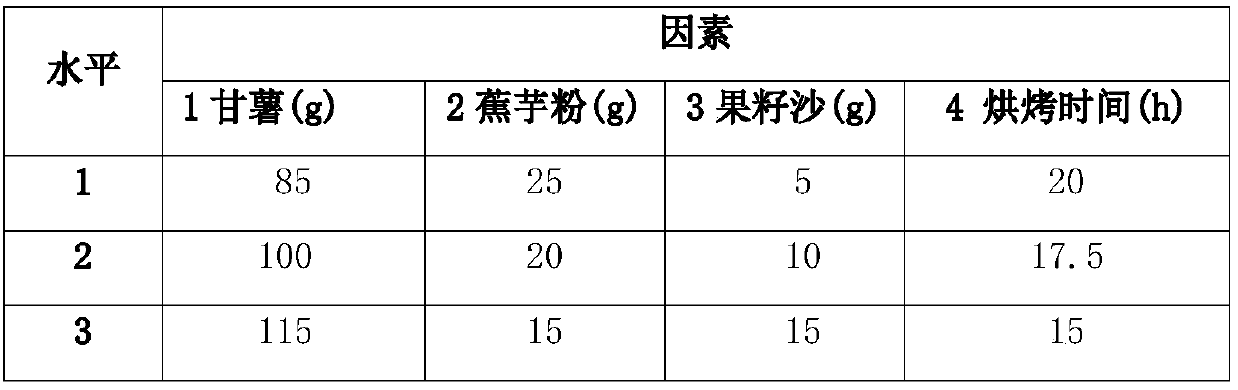

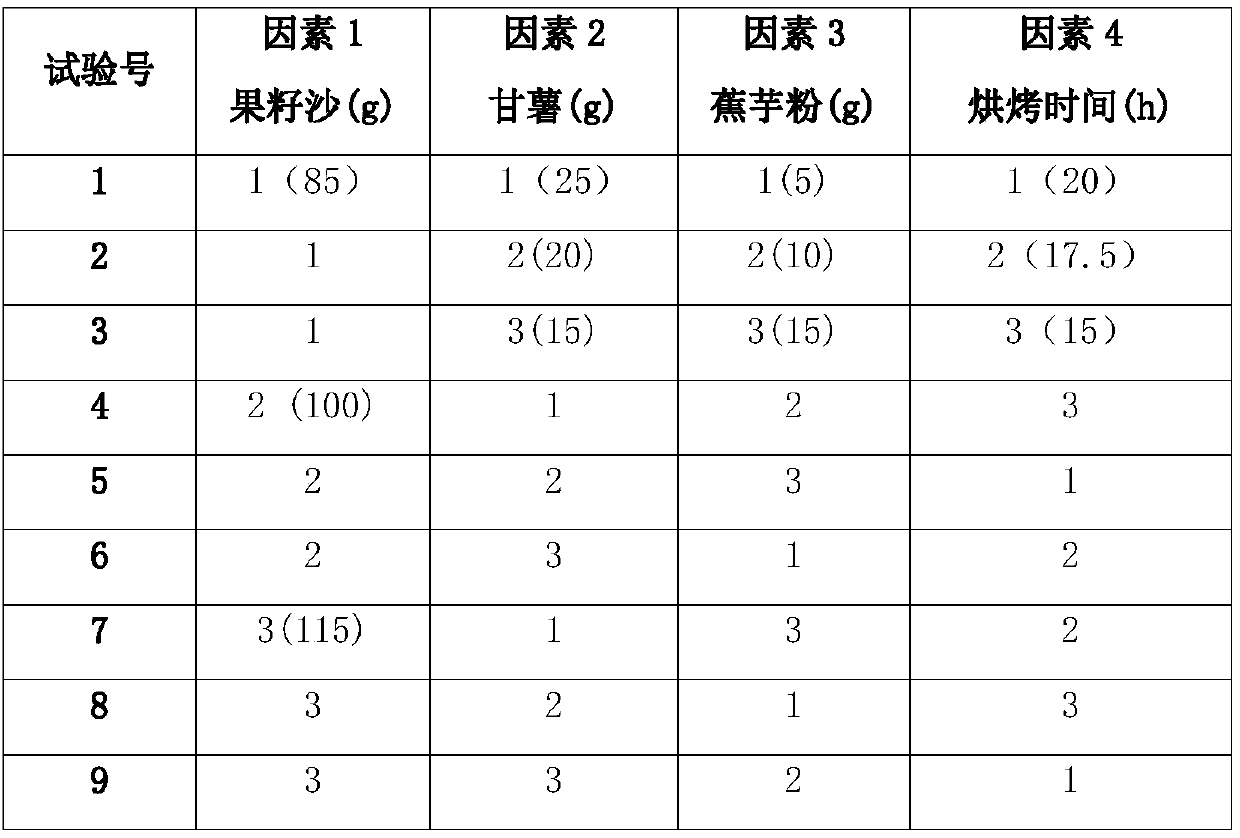

[0039] A processing method of sweet potato passion fruit cake, comprising the following steps:

[0040] (1) Pretreatment of each part of whole passion fruit

[0041] ①Extraction of husk juice

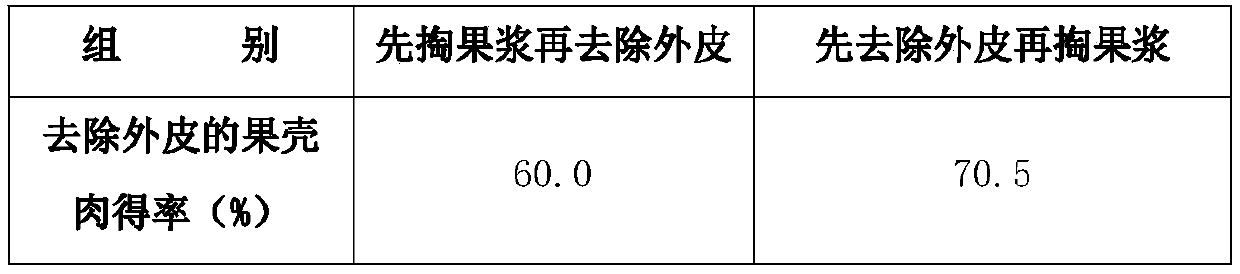

[0042] A, get fresh passion fruit and remove exocarp, take out fruit pulp to obtain fruit pulp and remove the husk meat of exocarp;

[0043] Passion fruit husk contains astringency, which will affect the taste of the product when it is used. If the astringency is removed after squeezing the juice, not only the product process is complicated, but the production cost is high, and the astringency removal will also take away part of the fruit aroma, reducing the need to add passion fruit husk However, the astringency of passion fruit shell is mainly concentrated on the exocarp, and the purpose of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com