Aluminum dihydrogen phosphate and steel fiber reinforced refractory castable and preparation method

A technology of aluminum dihydrogen phosphate and refractory castables, which is applied in the field of refractory materials, can solve the problems of increased corrosion rate, achieve the effects of preventing high-temperature sintering shrinkage, improving high-temperature mechanical properties, maintaining volume stability and creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

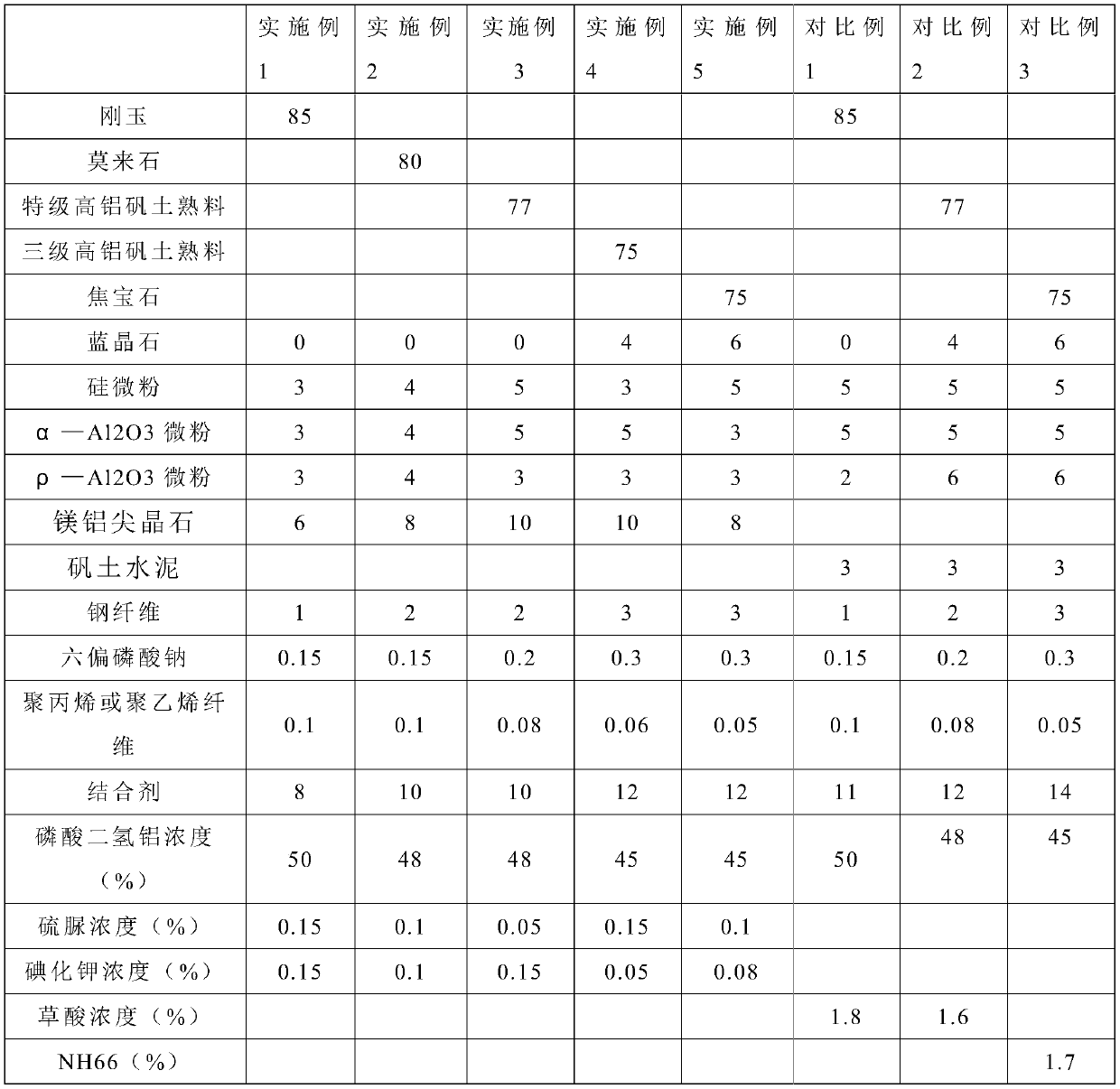

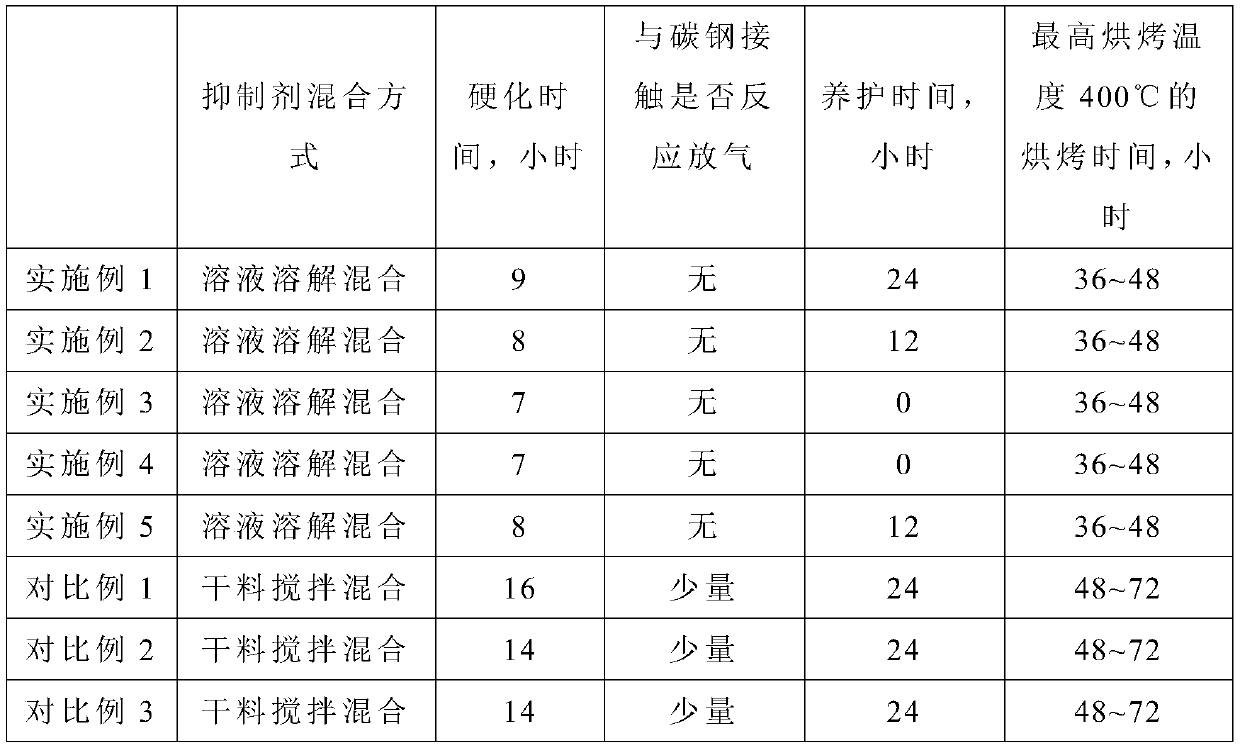

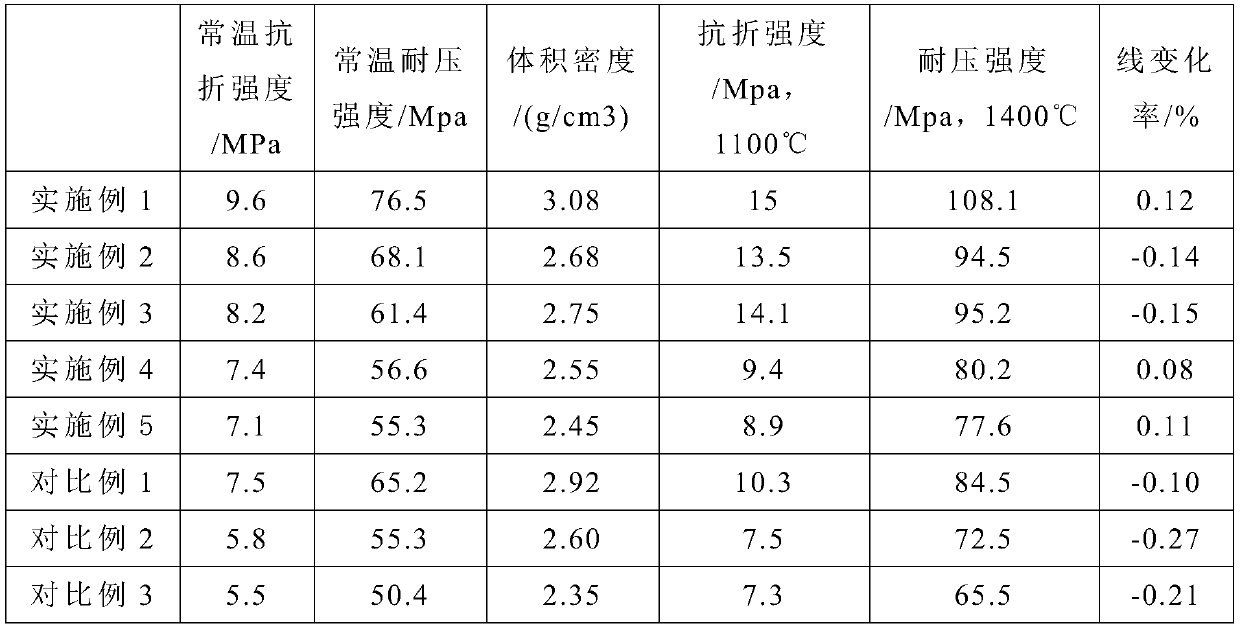

[0024] The present invention will be further described in detail below in conjunction with specific examples and comparative examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0025] By controlling the inhibitor compound composition and concentration in the aluminum dihydrogen phosphate aqueous solution, the selection of the type of aluminum-containing neutral refractory material, the particle size and addition amount of the main refractory material, the addition amount of additives and binders, the mixing time, molding method, and maintenance time, baking time and baking temperature and other process parameters, the prepared aluminum dihydrogen phosphate and inhibitors have less dosage, can be cast in direct contact with carbon steel, have good volume stability, high medium and high temperature strength, and thermal shock stability. Excellent, high density, low porosity, strong erosion resistance and wear res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com