Half-leaf curing method for reducing starch content of flue-cured tobacco

A baking method and technology of starch content are applied in the directions of tobacco, tobacco preparation, agricultural machinery and implements, etc., and can solve the problems of shortening the total baking time of a single kang, increasing fuel consumption, increasing environmental pollution, etc., and shortening the baking time. , The effect of increasing smoke capacity and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, "half-leaf" baking method reduces the starch content test of tobacco leaves (Hubei)

[0030] The content of starch in the upper part of the tobacco is relatively high, and the "half-leaf" baking is used to investigate the effect on reducing starch.

[0031] Materials and Methods:

[0032] 1.1 Test location: Xiaoguan Town, Xuanen County, Enshi City, Hubei Province

[0033] 1.2 Test materials: Yunyan 87, upper smoke

[0034] 1.3. Processing settings:

[0035] Baking in a downdraft oven with three treatments:

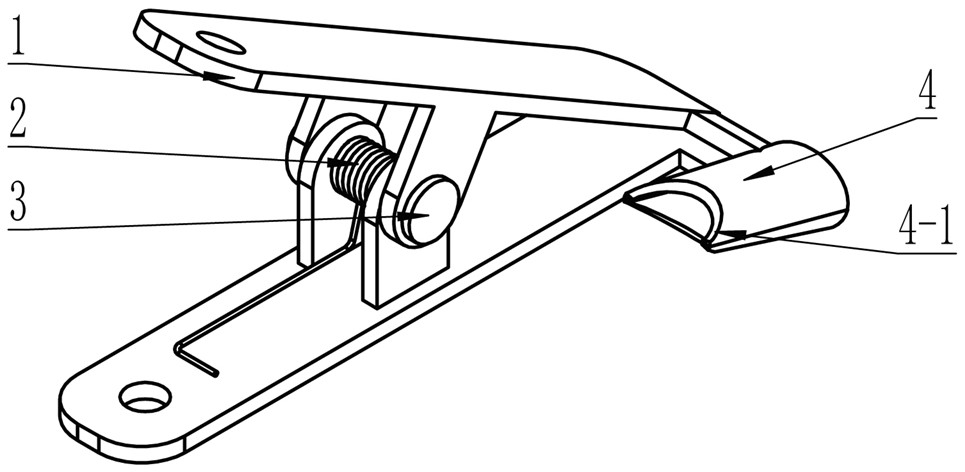

[0036] The complete leaf is along the side of the main tobacco rib, close to the main tobacco rib to divide a complete leaf into two, and bake it on a specially designed special tobacco rod hanging rod, with one side without ribs (treatment 1) and the other side with ribs (treatment 2) ). Conventional whole leaf binding roast (for treatment three).

[0037] Namely: Treatment 1: A1━half leaf is roasted without ribs, and half tobacco leaf is dried;...

Embodiment 2

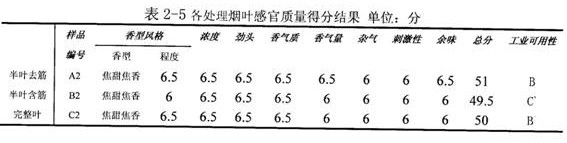

[0062] Example 2. Test of reducing the starch content of tobacco leaves by "half-leaf" baking method (Jia County, Henan Province)

[0063] 1 Materials and methods:

[0064] 1.1 Test site: Ningxian Songkang House, Jia County, Pingdingshan, Henan Province

[0065] 1.2 Test materials: medium smoke 100, upper smoke

[0066] 1.3. Processing settings:

[0067] Baking in a downdraft oven with three treatments:

[0068] The complete leaf is along the side of the main tobacco rib, close to the main tobacco rib to divide a complete leaf into two, and bake it on a specially designed special tobacco rod hanging rod, with one side without ribs (treatment 1) and the other side with ribs (treatment 2) ). Conventional whole leaf binding roast (for treatment three).

[0069] Namely: Treatment 1: A2━half leaf is roasted without ribs, and half tobacco leaf is dried; the roasting is terminated;

[0070] Treatment 2: B2━Roasting half leaves with tendons;

[0071] Treatment 3: C2━conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com