Production technology of peanuts

A production process and technology of peanut fruit, applied in the fields of food science, function of food ingredients, food drying, etc., can solve the problems of the surface taste of peanuts, and achieve the effect of consistent color and color as much as possible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

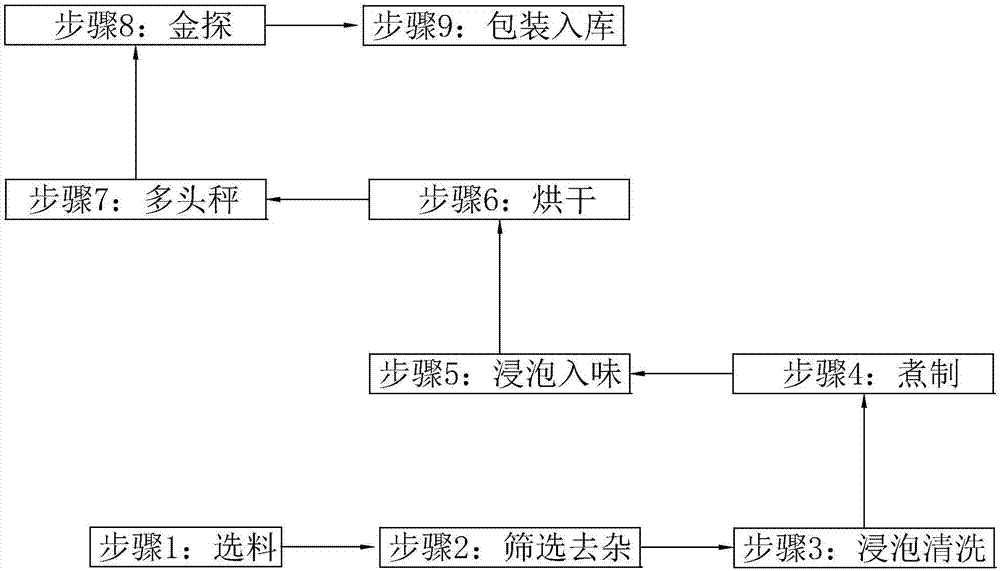

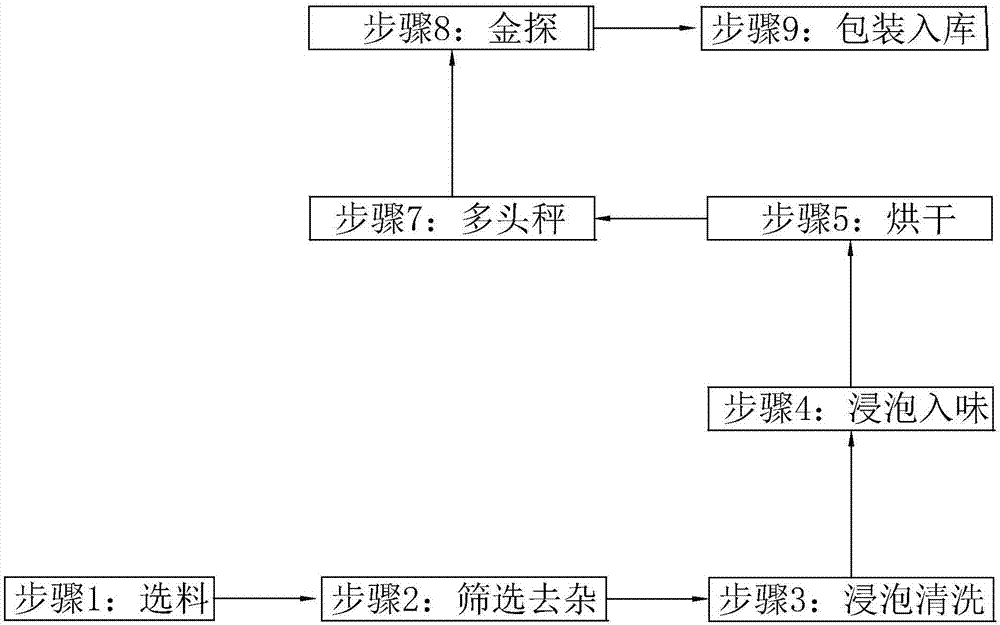

Method used

Image

Examples

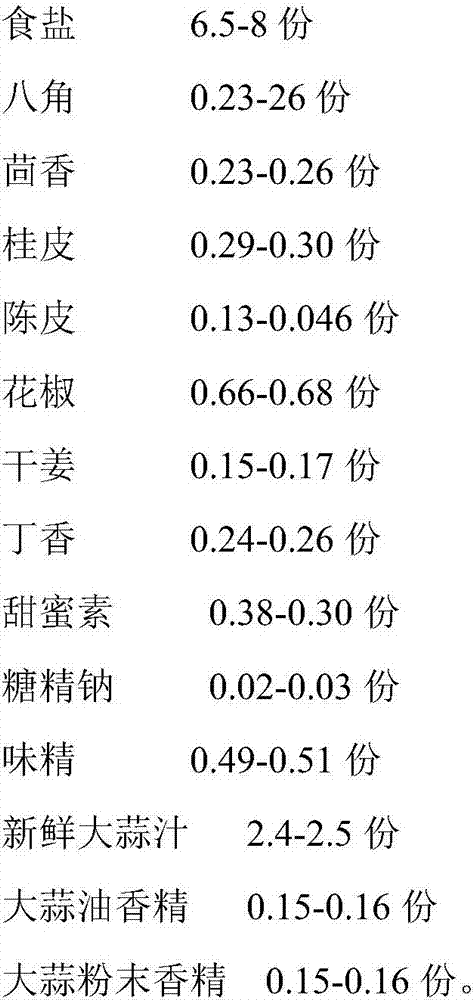

Embodiment 1

[0041] Take a clean container and add 6.5 parts of table salt, 0.15 parts of star anise, 0.15 parts of fennel, 0.25 parts of cinnamon, 0.15 parts of licorice, 0.25 parts of cyclamate, 0.01 parts of sodium saccharin, 0.23 parts of monosodium glutamate, 0.20 parts of fresh creamer, 0.15 parts of eggs After the cream essence and 0.15 parts of acesulfame potassium, stir evenly to form a milk flavor mixed seasoning.

Embodiment 2

[0043] Take a clean container, add 6.8 parts of table salt, 0.16 parts of star anise, 0.16 parts of fennel, 0.30 parts of cinnamon, 0.18 parts of licorice, 0.27 parts of cyclamate, 0.02 parts of sodium saccharin, 0.25 parts of monosodium glutamate, 0.25 parts of fresh creamer, 0.18 parts of eggs After the cream essence and 0.18 parts of acesulfame potassium, stir evenly to form a milk flavor mixed seasoning.

Embodiment 3

[0045] Take a clean container and add 6.7 parts of table salt, 0.15 parts of star anise, 0.15 parts of fennel, 0.28 parts of cinnamon, 0.15 parts of licorice, 0.25 parts of cyclamate, 0.01 parts of sodium saccharin, 0.25 parts of monosodium glutamate, 0.20 parts of fresh creamer, 0.15 parts of eggs After the cream essence and 0.15 parts of acesulfame potassium, stir evenly to form a milk flavor mixed seasoning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com